E300 Horizontal stretch wrapping machine

Project Information

The FHOPE Fully Automatic Horizontal Wrapping Machine E300 is an advanced solution for efficiently packaging long, straight items such as pipes, doors, panels, and aluminum profiles. With seamless automation, precise control, and customizable settings, it ensures secure and professional packaging while significantly reducing labor and material costs.

Key Features:

Rotating Ring: Fast, precise control of speed, tension & overlap.

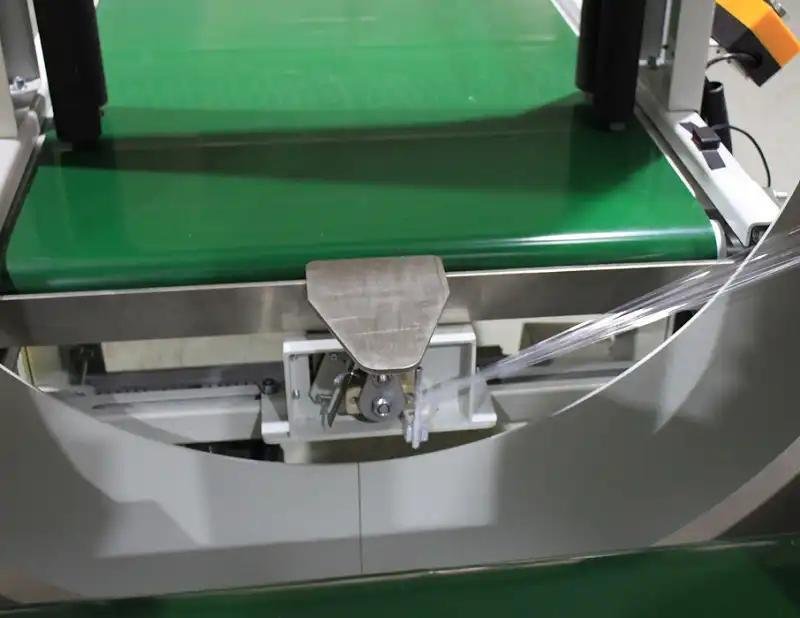

Automated Feed & Cut: PLC-driven with robotic arms.

Variable-Speed Conveyor: Motorized, gentle handling.

Real-Time Alerts: Immediate fault detection & guidance.

Multi-Film Flexibility: Adjustable for all sizes & materials.

Boost Packaging Efficiency and Reduce Operating Costs

The E400 Horizontal Ring Stretch Wrapper features a modular PLC-controlled design, installs on flat floors with no foundation work, and delivers stable, high-speed, unmanned bundle wrapping.

Key Value Drivers

- Consistent Tension: Dual-rubber-wheel drive delivers even film application, cutting material waste.

- High-Speed Automation: PLC-controlled sequences and adjustable speeds optimize cycle times.

- Rapid Deployment: Floor installation avoids civil works—get running fast.

- Comprehensive Safety: CE-rated guards and fault alarms protect personnel and uptime.

- Easy Operation: Touchscreen UI and under-1-hour training make non-technical staffing possible.

Features & ROI Comparison

| Feature / Component | Customer Benefit / ROI |

|---|---|

| Modular Ring & Dual Rubber-Wheel Drive | Stable rotation with adjustable friction ensures uniform tension—reduces film waste and rework. |

| PLC-Controlled Sequences | Sensor-based positioning automates wrap cycles, minimizes manual errors, and increases throughput. |

| Inverter-Driven Speeds (Ring 20–90 RPM; Conveyor 6–12 m/min) | Fine-tune wrap and feed rates to match bundle size and film type—optimize cycle time. |

| Adjustable Tension & Overlap (10%–90%) | Maintain consistent film tension across bundle sizes—prevent loose wraps and secure loads. |

| Soft-Surface Conveyors & Protective Guides | PU/PVC belts and gentle guides protect product surfaces from scratches. |

| Automatic Film Feed & Cut | Unmanned operation handles film loading, clamping, and clean cutting—cuts labor costs. |

| Floor Installation (≥ 1 t/m²) | No foundation needed—speed up installation and ROI. |

| CE-Rated Guards & Press-Down Devices | Enclosed moving parts and alarms ensure safe, compliant operation. |

| Standalone Control Panel & Touchscreen | Intuitive settings panel—under 1 hour training for new operators. |

| Fault Diagnostics & Alarms | Immediate fault display speeds troubleshooting and reduces downtime. |

| Modular Conveyor Integration | 2 × 2 m infeed/outfeed conveyors integrate seamlessly—eliminate bottlenecks. |

| High Annual Uptime & Environmental Compliance | Designed for 7,200 h/year with noise and emissions within regulatory limits. |

Technical Parameters

| Parameter | Specification |

|---|---|

| Bundle OD | 100-300mm |

| Bundle Length | >1000mm |

| Weight | 15-100kg |

| In-Feeding Conveyor Length | 2000mm with motor |

| Out-Feeding Conveyor Length | 2000mm with motor |

| Speed | 6~12m/min |

| Ring Speed | 20-90r/min |

| Wrapping Speed | 5-15m/min |

| Power Output | About 2.5kw |

| Power Voltage | 380v, 3PH, 60Hz |

| Packing Material | Polyethylene Foil OD: 100-200mm, Width: 100-200mm, ID: 50mm |

The E300 Horizontal Stretch Wrapping Machine is built for heavy-duty industrial applications, providing secure and efficient wrapping for long items like pipes, rods, and panels. With advanced features such as adjustable tension, variable speed control, and a robust design, it ensures consistent wrapping performance, enhanced product protection, and optimized packaging efficiency.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

Small Horizontal Stretch Wrappe

The E100 Horizontal Stretch Wrapping Machine is designed for wrapping elongated and irregularly shaped products such as p

View DetailsE200 Automatic Horizontal Orbit

The E200 Horizontal Stretch Wrapping Machine is designed for efficient packaging of elongated items like pipes, profiles,

View DetailsAutomatic Horizontal Spiral Str

The E400 Horizontal Stretch Wrapping Machine is designed for wrapping large and heavy elongated items such as pipes, pane

View DetailsE500 Orbital Ring Stretch Wrapp

Engineered for long, bulky loads—pipes, rods, panels—the E500 Horizontal Wrapping Machine combines high-speed stretch

View DetailsE600 Horizontal stretch wrappin

The E600 Horizontal Stretch Wrapping Machine is designed for heavy-duty wrapping of long and irregular items, such as pip

View DetailsE1000 Orbital Ring Stretch Wrap

The E1000 Horizontal Stretch Wrapping Machine delivers uniform, secure wrapping for oversized panels, pipes, and profiles

View DetailsE1400 Horizontal Orbital Stretc

The Big-Size Orbital Stretch Wrapping Machine is specifically designed for wrapping large items such as doors and panels.

View DetailsE1800 Automatic Horizontal Pane

The E1800 Horizontal Orbital Stretch Wrapper delivers heavy-duty, consistent, uniform wrapping for large items—doors, p

View DetailsE2400 Horizontal stretch wrappi

The E2400 Horizontal Stretch Wrapping Machine specializes in secure packaging of extra-large, heavy-duty items—panels,

View Details