Revolutionize Your Production Line with Intelligent Coiling

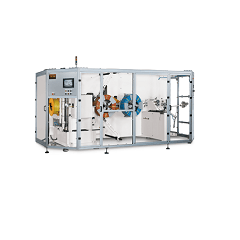

Our automatic coilers seamlessly integrate into your manufacturing process, transforming pipe handling into efficient, space-saving ribbon coils with unmatched reliability.

Seamless Automation Integration

Connect directly to your production line with automatic length counting and cutting capabilities for complete process automation.

Enhanced Operator Safety

Front-side unloading with protective door systems ensures complete operator safety during coil ejection and retrieval.

Smart Material Handling

Automated coil transfer to trolleys or receiving tables optimizes workflow and reduces manual handling requirements.

Customized Coiling Solutions

Multiple series available for different product specifications, ensuring perfect coiling performance for your specific application.

Maximize your production efficiency with our engineered coiling systems that bridge manufacturing and automated storage logistics.

Optimize Your Coiling Process

Project Overview & Advantages

Explore our specialized capabilities and successful case studies across various manufacturing sectors

Automatic pipe coiler Manufacturing Excellence

Automatic hose and pipe coiler and strapping machine line manufacutrer in China helps you find the automation solution after extruding machine with good price. Not man required for coiling process anymore...

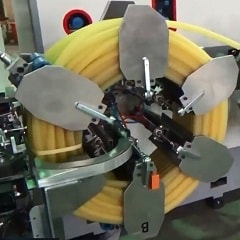

Horizontal Automatic Coiler

The Horizontal Automatic Coiler is an innovative machine designed for efficient wire coiling and packaging. With precise tension control, high-speed automation, and customizable settings, it ensures consistent coil formation and secure bundling. Ideal for industrial applications, it enhances productivity, reduces labor dependency, and delivers reliable, high-quality results for wire management.

Vertical Automatic Coiler

A Vertical Automatic Coiler is a specialized machine designed for efficiently coiling materials like wires, cables, or hoses into precise, compact rolls. Ideal for industrial applications, it automates the coiling process, enhancing speed, accuracy, and productivity. With customizable settings, it ensures consistent coil dimensions while minimizing labor efforts. Perfect for streamlining packaging

Precision Automatic Coiling Systems

Our advanced automatic coiling equipment transforms pipe processing with seamless integration into production lines, featuring automated length counting, precision cutting, and safe coil ejection for complete workflow automation.

Seamless Production Integration: Direct connection to manufacturing lines with automatic measurement and cutting capabilities for continuous operation.

Enhanced Operator Safety: Protected unloading system with safety doors that isolate winding zones while enabling front-access coil retrieval.

Versatile Material Handling: Multiple series available for different product specifications with automatic ejection to trolleys or receiving tables.

Production Speed Increase

Labor Reduction

Operation Accuracy

Safety Compliance

Selecting Your Optimal Automatic Coiling System

Critical Production Link

Automatic coilers serve as the vital connection between manufacturing processes and automated storage systems, ensuring smooth material transition while maintaining production continuity through precise length counting and cutting functions.

Customized Coiling Solutions

Our engineering team designs specialized coiling systems for various industrial applications, each featuring safe front-unloading mechanisms, operator protection systems, and compatibility with different receiving equipment for optimal workflow integration.

Request Coiling System Consultation

SHOWCASE & NEWS

Automatic Coiler Systems FAQ

Expert Answers to Your Automatic Coiling Equipment Questions

An automatic coiler is an industrial machine designed to transform continuous pipe or tubing into perfectly wound ribbon coils. It integrates seamlessly with your production line, automatically counting lengths and executing precise cuts. This advanced equipment ensures consistent coil formation while maintaining product integrity. By automating the coiling process, manufacturers achieve higher throughput, reduce labor costs, and minimize product damage. The system's intelligent design allows for smooth material transfer and reliable operation throughout extended production runs.

Our automatic coiler prioritizes operator safety through multiple protective features. The system includes interlocked safety doors that separate operators from the winding mechanism during operation. When the coiling cycle completes, the machine automatically ejects finished coils onto designated trolleys or receiving tables through the front unloading system. This design eliminates manual handling of heavy coils and prevents exposure to moving parts. Safety sensors and emergency stop systems provide additional protection, ensuring compliance with international industrial safety standards for pipe coiling equipment.

Our automatic coiling machines accommodate diverse material types and dimensional specifications. They efficiently process various piping materials including PVC, polyethylene, copper tubing, and flexible metal conduits. Standard models handle pipe diameters from 6mm to 50mm, with custom solutions available for specialized applications. The coiling systems can produce ribbon coils with diameters ranging from 800mm to 2000mm, tailored to your storage and shipping requirements. Each machine is engineered to maintain consistent coil tension and prevent material deformation throughout the winding process.

Choosing the optimal automatic coiler requires evaluating several key factors. Consider your production volume, pipe material characteristics, required coil dimensions, and integration needs with existing equipment. Our engineering team assesses your specific application to recommend the most suitable coiler series. We analyze your automation goals, available floor space, and desired connection to downstream processes like automated storage systems. With multiple coiler configurations available, we ensure perfect compatibility with your production chain while maximizing automation benefits and return on investment.

Yes, our automatic coilers feature advanced integration capabilities for seamless connection to your production automation ecosystem. They communicate with upstream and downstream equipment using standard industrial protocols including PROFIBUS, Ethernet/IP, and Modbus TCP. The coiler's control system interfaces with production line computers for automatic length counting, cutting commands, and production data logging. This integration enables complete automation from raw material feeding through to coiled product handling, including connection to automated storage and retrieval systems for uninterrupted material flow throughout your facility.

Automatic coilers require minimal but regular maintenance to ensure optimal performance. Daily maintenance involves visual inspections and cleaning of critical components (approximately 10-15 minutes). Weekly tasks include checking tension systems, verifying sensor alignment, and lubricating moving parts (30-45 minutes). Monthly maintenance encompasses thorough inspection of wear components, electrical system verification, and software updates (2-3 hours). We provide comprehensive maintenance schedules, operator training, and remote support services. Most maintenance activities can be performed during planned production breaks, minimizing impact on your manufacturing operations.

Our Clients Around The World

We are honored to serve outstanding enterprises worldwide, establishing long-term stable partnerships. Below are some of our trusted partners who have chosen our manufacturing solutions.

Ready to Start Your Next Manufacturing Project?

Impressed by our projects? If you have similar requirements or want to discuss your project ideas, contact our expert team immediately for a free initial consultation.

Contact Our Experts