Tired of Costly and Risky Manual Pallet Transfer?

Manual pallet handling is slow, labor-intensive, and a leading cause of product damage and workplace injuries. It's time for a smarter solution.

Slow Load Transfers

Manual pallet swapping and product transfer create significant bottlenecks in your warehouse or production line.

High Product Damage Risk

Unstable manual handling during pallet rotation or exchange often leads to costly product loss and damage.

Labor-Intensive Operations

Relying on heavy manual labor for pallet management increases operational costs and limits your workforce's potential.

Inflexible Workflow

Lack of adaptable equipment like mobile pallet changers restricts your ability to respond to dynamic logistics needs.

Project Overview & Advantages

Explore our specialized capabilities and successful case studies across various manufacturing sectors

Pallet Inverter Manufacturing Excellence

Efficiently streamline material handling with our Pallet Inverter and Pallet Changer solutions. Designed for safety, durability, and precision, these systems simplify pallet rotation and replacement, reducing labor costs and minimizing product damage. Ideal for warehouses, logistics, and manufacturing industries. Explore customizable options to meet your specific needs.

Mobile Pallet Inverter

A mobile pallet inverter is a versatile machine designed to rotate or invert pallet loads for easy access, replacement, or reorganization. Its mobility allows for flexible use across different locations, improving efficiency in warehouses and manufacturing facilities. It enhances safety, reduces manual labor, and ensures smooth handling of heavy or delicate goods.

Pallet Changer

A pallet changer is a specialized machine used to transfer loads from one pallet to another efficiently. It streamlines operations in warehouses and logistics by enabling easy pallet replacement without manual lifting. Ideal for industries requiring hygiene compliance or pallet standardization, it enhances productivity, safety, and workflow efficiency.

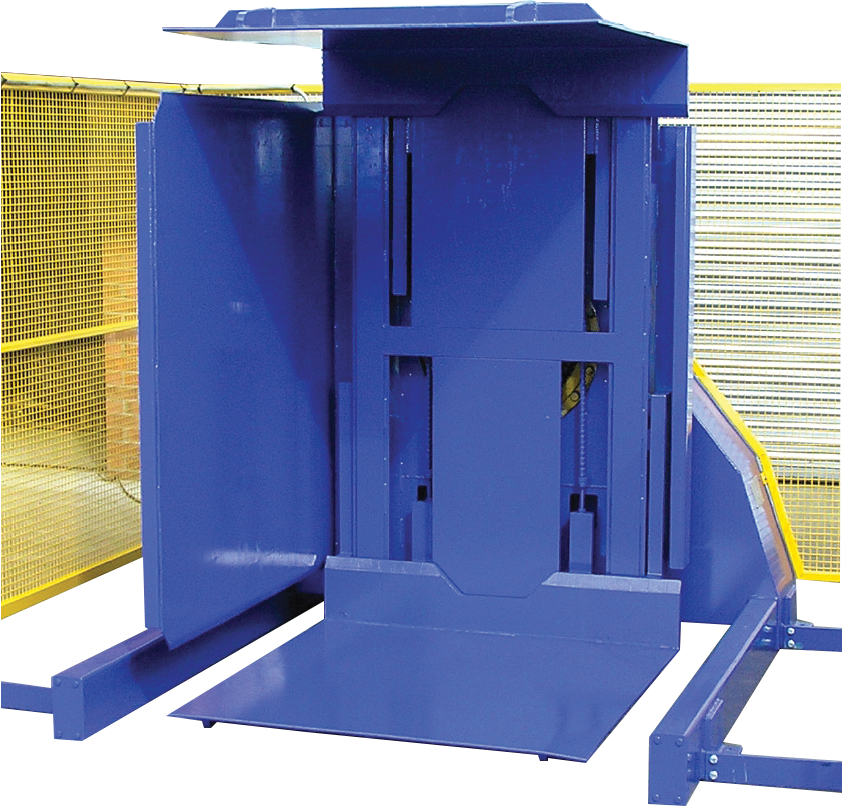

Stationary Pallet Inverter

There are several types stationary pallet inverters and pallet changing system to help to quickly rotate, swap, and transfer the heavy objects with minimal effort in safety way.

Inline Pallet Changer

The Automatic Pallet Changer is an inline system that seamlessly integrates with pallet stackers and conveyors to automate pallet loading, exchange, accumulation and load transfer—eliminating manual handling, boosting throughput and ensuring continuous, synchronized material flow.

Heavy-Duty Pallet Inverter Systems

Fhope's industrial pallet inverters deliver precision load transfer solutions with robust engineering, enabling seamless pallet exchange and product rotation while maintaining complete load integrity throughout the handling process.

Multi-Angle Rotation Capability: Advanced 95° pallet exchangers and V-shape changers accommodate diverse load configurations and warehouse layouts.

Damage Prevention Technology: Patented clamping systems ensure zero product compression during transfer operations.

Mobile & Stationary Configurations: Flexible deployment options including electric, hydraulic, and hybrid power systems for various industrial environments.

Labor Reduction in Load Transfer

Product Damage Prevention Rate

Average Pallet Exchange Time

Global Installations

Logistics Center Achieves 300% ROI with Pallet Inverter Implementation

Operational Challenge

A major European logistics provider faced significant product damage and labor costs during manual pallet transfers, with annual losses exceeding $280,000 from damaged goods and inefficient material handling processes.

Fhope Engineering Solution

We installed a customized pallet inverter system with automated positioning and intelligent clamping technology. The implementation eliminated manual handling, reduced transfer time by 75%, and achieved complete product protection during pallet exchanges across their distribution network.

Request Your Custom Solution

SHOWCASE & NEWS

Pallet Inverter Systems: Essential Questions Answered

Expert Insights on Automated Pallet Handling and Load Transfer Solutions

A pallet inverter is an industrial machine designed to transfer loads between pallets while maintaining product integrity. This innovative equipment securely grips the load and rotates it to a new pallet base, eliminating manual handling. For warehouse operations, it significantly reduces labor costs by up to 70% and minimizes product damage during pallet replacement. The system streamlines operations by enabling quick pallet swaps for damaged bases, efficient product rotation, and seamless transfers between different pallet types, making it an essential tool for modern logistics and storage facilities.

We provide three main pallet inverter configurations to suit different operational needs. The 95° pallet exchanger is ideal for standard warehouse applications, offering smooth load transfers with minimal space requirements. V-shape changers provide exceptional stability for fragile or unstable loads, while mobile inverters deliver flexibility for operations across multiple locations. For high-volume facilities, we recommend our heavy-duty models capable of handling up to 3,000kg loads. Our engineering team conducts facility assessments to recommend the optimal solution based on your pallet types, load characteristics, and operational workflow requirements.

Automated pallet inversion technology eliminates the primary causes of product damage inherent in manual handling. Our systems feature precision hydraulic controls that maintain consistent pressure distribution throughout the transfer process, preventing load shifting and compression damage. Advanced clamping systems with pressure sensors ensure secure grip without excessive force, while smooth 180-degree rotation mechanisms prevent sudden movements that can destabilize loads. Facilities implementing our pallet inverters typically report 85-90% reduction in product damage claims and significantly lower insurance premiums due to improved safety records.

Our pallet inverters incorporate multiple safety systems to protect both operators and products. Standard safety features include emergency stop buttons at multiple access points, anti-trap protection on all moving parts, and overload detection systems that automatically halt operation if weight limits are exceeded. Additional safety measures include safety light curtains that stop machine operation when breached, mechanical locking systems during rotation cycles, and fail-safe hydraulic valves that prevent unexpected movements. All our equipment meets international safety standards including CE certification and includes comprehensive operator training programs to ensure safe usage.

Yes, our pallet inverter systems are designed with adaptability in mind. Standard models accommodate Euro pallets (800x1200mm), industrial pallets (1000x1200mm), and custom sizes up to 1600x1600mm. The adjustable clamping systems handle load heights from 500mm to 2200mm and weights from 500kg to 3000kg. Specialized configurations are available for challenging loads including unstable stacks, cylindrical items, and temperature-sensitive products. Our quick-change adapters allow facilities to switch between different pallet types within minutes, maximizing operational flexibility without requiring multiple specialized machines.

Most facilities achieve complete ROI within 12-18 months through multiple cost-saving channels. Labor cost reduction typically accounts for 40-50% of savings by eliminating 2-3 manual workers per shift. Product damage reduction contributes 25-30% in saved materials and insurance costs. Additional savings come from reduced pallet replacement expenses (15-20%) and improved operational efficiency (10-15%). High-volume operations processing 50+ pallets daily often see faster returns, with some clients reporting full ROI in under 10 months. We provide detailed ROI analysis during the consultation phase based on your specific operational metrics and volume projections.

Still have questions about our pallet handling solutions?

Get Personalized AdviceOur Clients Around The World

We are honored to serve outstanding enterprises worldwide, establishing long-term stable partnerships. Below are some of our trusted partners who have chosen our manufacturing solutions.

Ready to Start Your Next Manufacturing Project?

Impressed by our projects? If you have similar requirements or want to discuss your project ideas, contact our expert team immediately for a free initial consultation.

Contact Our Experts