Revolutionize Your Steel Coil Protection Strategy

Discover how our automated packaging systems eliminate production bottlenecks while ensuring superior coil protection during transit and storage.

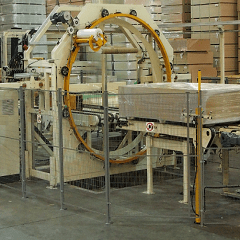

Automated Wrapping Systems

Our horizontal wrapping machine technology streamlines packaging workflows, handling up to 30 coils per hour with precision.

Cost-Efficient Operation

Advanced track wrapping machine solutions reduce labor costs by 60% while minimizing material waste through optimized consumption.

Consistent Quality Assurance

Precision stretch wrapping machine applications ensure uniform tension and coverage, eliminating corrosion and surface damage.

Enhanced Safety Protocols

Automated profile baler integration removes workers from hazardous environments, significantly reducing workplace incidents.

Join global steel manufacturers who trust FHOPE packaging technology for their most demanding coil protection requirements.

Request Custom Solution

Project Overview & Advantages

Explore our specialized capabilities and successful case studies across various manufacturing sectors

Orbital stretch wrapper Manufacturing Excellence

Fhope Machinery, a professional manufacturer of packaging equipment, can customize horizontal winding packaging machine solutions for you. The equipment can achieve good packaging effect, high efficiency, easy operation, affordable price and high machine stability. Is an excellent choice for your product packaging.

Semiauto horizontal wrapper

A Semi-Auto Horizontal Wrapper is a versatile packaging machine designed for wrapping elongated products like pipes, profiles, or panels. Combining manual and automated functions, it provides reliable wrapping with stretch film or other materials, ensuring product protection. Ideal for medium-scale operations, it offers flexibility, efficiency, and cost-effective packaging solutions.

Customize orbital wrapper

A Customized Orbital Wrapper is tailored to meet specific packaging needs for irregular or unique-shaped products. Designed for precision and flexibility, it offers adjustable wrapping parameters, materials, and configurations. Ideal for industries with diverse packaging requirements, it enhances efficiency, protects products, and ensures consistent, high-quality packaging .

Automatic horizontal stretch wrapper

An Automatic Horizontal Stretch Wrapper is an advanced packaging machine designed for efficiently wrapping long or irregularly shaped products, such as pipes, doors, or panels. Featuring automated film application and tension control, it ensures consistent wrapping quality. This machine enhances productivity, reduces material waste, and provides secure packaging for safe transport and storage.

Precision Horizontal Wrapping & Profile Baling Solutions

Our industrial-grade horizontal wrapping machines and profile baler-FHOPE systems deliver unmatched packaging precision for metal profiles, construction materials, and industrial components, featuring intelligent control and robust track wrapping technology.

Multi-Directional Wrapping Capability: Advanced track wrapping machine design enables horizontal and vertical film application for complete material protection.

Intelligent Tension Control: Precision stretch wrapping machine technology maintains optimal film tension across varying load sizes and shapes.

Integrated Baling Technology: Profile baler-FHOPE systems combine compression and wrapping for streamlined material processing and storage optimization.

Faster Operation Cycle

Film Material Savings

Operational Reliability

Global Installations

Aluminum Profile Manufacturer Achieves Packaging Excellence

Production Challenge

A leading European aluminum extrusion company struggled with manual packaging inefficiencies, product damage during transit, and inconsistent bundle stability across their profile manufacturing operations.

Engineering Solution & Results

We implemented a complete horizontal wrapping machine system integrated with our profile baler-FHOPE technology. The automated track wrapping machine solution achieved 28 bundles per hour with zero product damage and reduced film consumption by 22% compared to previous methods.

Request Custom Solution Analysis

SHOWCASE & NEWS

Industrial Packaging Systems: Technical FAQs

Professional Guidance on Horizontal, Track, and Stretch Wrapping Solutions

Our horizontal wrapping machine delivers superior performance for heavy industrial applications with its robust construction and precision engineering. The system features advanced film tension control that ensures consistent wrapping pressure, preventing load shifting during transportation. With customizable programming for different material types, it handles weights up to 30 tons while maintaining optimal film usage. The automated operation reduces labor requirements by 70% compared to manual methods.

The track wrapping machine incorporates intelligent speed synchronization technology that automatically adjusts to your production flow. With variable frequency drives and motion control systems, it maintains consistent wrapping quality at speeds from 5 to 30 loads per hour. The modular design allows for seamless integration with existing conveyor systems, while the programmable logic controller ensures precise film application regardless of production fluctuations.

Our stretch wrapping machine revolutionizes efficiency through patented pre-stretch technology that delivers up to 300% film stretch capability. This advanced system reduces film consumption by 35% while providing superior load containment. The machine features touch-screen controls with pre-set wrapping patterns and real-time monitoring of film usage. With automatic load height detection and tension control, it ensures consistent performance across diverse packaging requirements.

The profile baler-FHOPE system employs adaptive compression technology that automatically adjusts pressure based on material density feedback. Using advanced sensors and hydraulic control systems, it optimizes bale density for various materials from light packaging waste to heavy industrial scrap. The intelligent control system monitors material flow and adjusts compression cycles accordingly, ensuring consistent bale quality while maximizing throughput efficiency.

All our wrapping machines incorporate comprehensive safety systems including emergency stop circuits, safety light curtains, and overload protection. The horizontal wrapping machine features interlocked guarding systems, while the track wrapping machine includes anti-collision sensors. Our stretch wrapping machines come with automatic fault detection and remote monitoring capabilities. The profile baler-FHOPE system includes pressure monitoring and emergency reversal functions for maximum operator protection.

We specialize in customizing our packaging systems to meet unique industry needs. The horizontal wrapping machine can be configured with specialized film types and wrapping patterns. Track wrapping machines are adaptable to various floor layouts and production configurations. Stretch wrapping systems can incorporate specialized film carriage options and integration with existing automation. The profile baler-FHOPE offers modular components that can be tailored to specific material handling requirements and space constraints.

Our Clients Around The World

We are honored to serve outstanding enterprises worldwide, establishing long-term stable partnerships. Below are some of our trusted partners who have chosen our manufacturing solutions.

Ready to Start Your Next Manufacturing Project?

Impressed by our projects? If you have similar requirements or want to discuss your project ideas, contact our expert team immediately for a free initial consultation.

Contact Our Experts