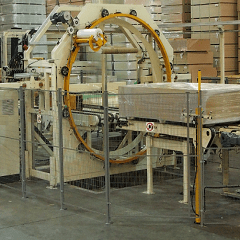

Six Sided Horizontal Orbital Stretch Wrapper for Board

Project Information

The Six-Sided Orbital Horizontal Stretch Wrapper is a cutting-edge packaging machine designed for comprehensive protection of products like plywood boards, MDF boards, and recyclable materials. Offering full six-sided coverage, it ensures products are safeguarded against moisture, dust, and environmental damage while promoting eco-friendly packaging practices with recyclable materials.

Key Features:

Six-sided coverage wraps edges and corners uniformly.

Circular ring with adjustable overlap maximizes material use.

Inverter-controlled speed and tension ensure precise wrapping.

Six-Sided Horizontal Orbital Stretch Wrapper

Protect plywood and MDF on all six faces and corners. Cut film waste, lower labor, and boost throughput—rain or shine.

Technical Data: Sealing Part

| Parameter | Specification |

|---|---|

| Control | PLC |

| Structure Material | Carbon steel |

| Packing Objects (L × W × H) | 900–2400 mm × 200–1200 mm × 100–800 mm |

| Weight | 20–100 kg |

| Height of Working Table | Approx. 800 mm |

| Conveyor Speed | Approx. 4–9 m/min |

| Packing Material | Bubble film + stretch film |

| Sealing Part Power Consumption | Approx. 6.5 kW |

| Power Supply | 230 V, 3 phase, 50 Hz |

| Air Supply | 6–8 kgf/cm² |

The Challenge

- Exposed Corners: Traditional wraps leave edges vulnerable to moisture and dust.

- Uneven Tension: Inconsistent speed or friction causes tight spots or loose film.

- High Volume: Simple methods stall when demand surges.

- Film Handling: Hoisting and swapping heavy rolls is slow and risky.

- Labeling Steps: Separate marking adds workflow complexity.

- Line Sync: Mismatched conveyors and stations trigger stoppages.

- Safety & Maintenance: Heavy parts need clear alerts and quick access.

- Sustainability: Demand for recyclable films and lower energy use is growing.

Solution & Benefits

- Orbital Ring Wrap: Uniformly covers all faces and corners—no gaps, no weak points.

- Adjustable-Friction Wheels: Precise tension control slashes film usage and prevents board deformation.

- Soft Start/Stop: Smooth ring acceleration avoids jerks and film tears.

- Auto Position Reset: Photoelectric sensors guarantee perfect alignment each cycle.

- Support Rollers & Press-Down: Hold boards steady to eliminate shifting and vibration.

- Elevated Platform & Hoist: Load heavy rolls safely in seconds—no strain, no delays.

- Quick-Change Film Cassette: Swap recyclable films in under a minute to keep lines moving.

- Inline Label Integration: Apply barcodes or labels during wrap to streamline traceability.

- PLC/HMI Control: Intuitive touchscreen cuts setup and training time.

- Tear & Fault Detection: Instant stop and alert on film breaks—zero defective packs.

- Energy-Efficient Drives: Inverter control reduces power draw and lowers operating costs.

- Modular, Compact Frame: Fits existing lines with minimal foundation work.

- Clear Diagnostics: HMI fault codes speed maintenance and reduce downtime.

Request a Quote

Ready for full six-sided protection with recyclable film and inline labeling? Contact us for custom specs, drawings, and pricing today.

The Six-Sided Horizontal Orbital Stretch Wrapper for Board offers complete wrapping coverage for boards and flat items, ensuring secure and durable packaging. Designed for efficiency, it wraps all six sides with adjustable tension to meet diverse needs. Its sturdy construction and easy operation make it ideal for industries requiring reliable protection during transport and storage.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

Pipe Horizontal Orbital Wrappin

The Pipe Horizontal Orbital Wrapping Machine is engineered for efficient and secure packaging of pipes and cylindrical it

View DetailsHorizontal Orbital Wrapping Mac

The Horizontal Orbital Wrapping Machine for Rod and Bar is designed to provide efficient and secure packaging of long, sl

View DetailsAluminum Horizontal Orbital Wra

Optimize aluminum profile packaging with PLC/HMI-controlled centering rollers and quick material change. Request a quote

View DetailsProfile Horizontal Orbital Wrap

The Profile Horizontal Orbital Wrapping Machine E1400 is designed for efficient and secure wrapping of profiles, rods, an

View DetailsSpiral Orbital Wrapper

The Spiral Orbital Wrapper is a versatile packaging machine designed for wrapping elongated items like pipes, rods, and p

View DetailsHorizontal Ring Stretch Wrapper

The Horizontal Ring Stretch Wrapper is a high-performance packaging machine designed for wrapping long and irregular item

View DetailsHorizontal Stretch Wrapping Mac

The Horizontal Stretch Wrapping Machine for Pallets is designed to securely wrap palletized loads horizontally, ensuring

View DetailsHorizontal Orbital Stretch Wrap

The Horizontal Orbital Stretch Wrapper is engineered for wrapping long and irregularly shaped items with a secure stretch

View DetailsFurniture stretch wrapping mach

The Furniture Stretch Wrapping Machine is designed for securely packaging furniture and bulky items with stretch film. Id

View DetailsEPS Panel Wrapping Machine

The EPS Packing Machine is designed for efficient and secure packaging of expanded polystyrene (EPS) products. Ideal for

View DetailsPanel Horizontal Orbital Stretc

The Panel Horizontal Orbital Wrapping Machine is specifically designed for wrapping flat panels, boards, and similar larg

View Details