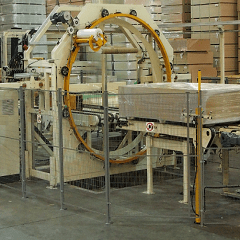

Pipe Horizontal Orbital Wrapping Machine

Project Information

The Steel Tube Wrapping Machine is a robust and efficient packaging solution designed for steel tubes, bars, sheets, and bundles. It ensures secure and professional wrapping, reducing costs and improving protection during transportation.

Key Features:

Durable Ring Design: 5-Year Warranty

Flexible Modes: Manual/Semi-Auto

Fast Wrapping: 1-Min Wrap

Enhanced Protection: Anti-Shift

Custom Integration: Easy Fit

Why Manual Wrapping Falls Short

Drains Productivity: 10+ minutes per bundle erodes throughput and inflates labor costs.

Unpredictable Tension: Uneven wrap leads to film waste or damaged bundles.

Surface Damage: Scratches and dents compromise quality—especially for coated tubing.

One-Size-Does-Not-Fit-All: Wide OD (300–2000 mm) and weight (100–5000 kg) range overwhelms manual methods.

Slow, Complex Setup: Foundations and specialist installers delay deployment.

High Consumable Use: Excess film, banding, and cartons drive up material spend.

Safety Risks: Manual handling exposes operators to pinch points and fatigue.

Technical Specifications

| Parameter | Specification |

|---|---|

| Product Name / Model | Steel Tube Horizontal Orbital Wrapping Machine |

| Supported Bundle OD | 300–1800 mm |

| Bundle Length | 2000–8000 mm |

| Bundle Weight | 100–5000 kg |

| Power Supply | AC 380 V, 50/60 Hz (or per requirement) |

| Power (Motor Rating) | 6.0 kW |

| Film Width | Up to 500 mm stretch film (PE) or compatible paper/knit belt |

| Turning Speed | 20–60 r/min (inverter-controlled) |

| Wrapping Speed | 2–12 m/min |

| Overlap Rate | 20%–90% |

| Tension Control | Automatic film draw-back device |

| Installation Requirements | Flat, hard ground ≥1 ton/m²; no foundation needed; standard utilities |

| Operation Training | Non-technical personnel up to speed within 1 hour |

| Safety Features | Electro-welded mesh guards; protective rails; automatic alarms |

| Warranty | Ring structure: 5 years |

| Throughput & ROI | Wrap cycle ~1 minute vs. ~10 minutes manually; reduces labor by ~50% |

| Integration Options | Optional conveyors, PLC interfaces for automatic line connection |

| Environmental & Compliance | Meets noise and emission standards for industrial equipment |

| Maintenance Access | Clear diagnostics; easy access to components |

Introducing the Steel Tube Horizontal Orbital Wrapper

Rock-Solid Ring with 5-Year Warranty – Ensures continuous operation under heavy loads.

Auto Tension-Control – Delivers uniform wrap, reduces film use, and eliminates loose ends.

Wide Range Handling – Covers OD 300–2000 mm, lengths to 8000 mm, weights up to 5000 kg in one system.

Quick, Foundation-Free Install – Mounts on flat, hard ground; up and running in under an hour.

PLC-Driven, Photocell-Guided – Automates cycles, syncs conveyors, and guarantees precise start/stop.

Variable Speed & Overlap – Adapt turn (20–60 rpm) and wrap (2–12 m/min) speeds plus 20–90% overlap for optimal cycle time.

Material Flexibility – Accepts PE film, VCI paper, knit belt, or combinations for corrosion and moisture protection.

Built-In Safety & Diagnostics – Mesh guards, alarm indicators, and clear error messages keep staff safe and uptime high.

Forklift-Ready Station – Simple bundle loading/unloading accelerates workflow.

Benefits You’ll Measure

50% Less Labor – Wrap cycle drops from ~10 min to ~1 min.

Lower Material Costs – Precise tension and overlap cut film consumption.

Faster ROI – Rapid deployment and minimal training deliver payback in weeks.

Enhanced Safety – Automated operation reduces manual handling and associated risks.

Seamless Integration – PLC interfaces plug into existing lines, boosting end-of-line throughput.

Perfect For

Steel Tube & Pipe Manufacturers

Metal Bar & Section Producers

Structural Steel Assemblers

Heavy Equipment Parts Suppliers

Logistics & Distribution Centers

Shipyards & Offshore Suppliers

Contract Packaging Providers

Request Your Quote

Ready to boost safety, cut costs, and accelerate throughput? Contact our team with your bundle specs and production goals. We’ll tailor a solution and deliver detailed drawings and competitive pricing—fast.

The Solution: Features & Benefits of the Steel Tube Horizontal Orbital Wrapping Machine

| Feature / Component | Benefit / ROI |

|---|---|

| Robust Ring Structure with 5-Year Warranty | Durable, long-lasting performance under heavy loads; minimizes downtime and maintenance costs. |

| Automatic Tension-Control Film Draw-Back Device | Maintains consistent wrap tension across varied bundle sizes; prevents loose wraps and excessive film consumption. |

| Wide Size Range Capability | Handles OD 300–2000 mm, lengths 2000–8000 mm, weights 100–5000 kg in one machine; avoids need for multiple wrappers. |

| Quick Installation & Operation (<1 Hour Training) | Mounts on flat, hard ground without foundations; intuitive controls let non-technical staff start wrapping bundles quickly, reducing commissioning time. |

| PLC-Driven Operation & Photocell Positioning | Automates wrap cycles, synchronizes conveyors and ring rotation; ensures accurate start/stop positions, avoids miswraps, and increases line throughput. |

| Inverter-Controlled Ring & Conveyor Speeds | Adjustable turn speed (20–60 r/min) and wrapping speed (2–12 m/min) adapt to bundle dimensions and film type for optimized cycle times. |

| Adjustable Overlap Rate (20%–90%) | Fine-tunes wrap coverage for secure protection and minimized film use, lowering material costs. |

| Support for Multiple Packing Materials | Accepts PE/stretch film, knit belt, VCI paper, or combinations; provides flexibility for corrosion protection or specialized needs. |

| Safety Guards & Easy Maintenance | Electro-welded mesh guards and protective rails shield operators; clear indicator alarms and diagnostics simplify troubleshooting and upkeep. |

| Forklift-Compatible Wrapping Station | Allows straightforward loading/unloading of tray or bundle by forklift; supports manual or semi-auto orientation for varied workflows. |

| Seamless Production Line Integration | Can connect to automatic packing lines; PLC interfaces enable smooth material flow from bundle prep through wrapping, boosting throughput. |

| Labor & Material Savings | Reduces wrapping time from ~10 minutes manually to ~1 minute per cycle; cuts labor costs by ~50% and reduces need for banding/cartons. |

Ideal Applications & Industries

Steel Tube & Pipe Fabricators: Secure stretch-wrap or paper wrap of tube bundles for storage and sea transport, preventing shifting and corrosion.

Metal Bar & Section Producers: Wrap bundles of bars, sections, or rods with consistent tension for handling and shipping.

Structural Steel & Tube Assemblers: Protect welded assemblies or bundled profiles during transit.

Heavy Equipment & Machinery Parts: Wrap large or heavy cylindrical parts to safeguard surfaces and facilitate handling.

Logistics & Distribution Centers: Automate end-of-line wrapping of heavy bundles to increase throughput and reduce labor.

Shipyards & Offshore Suppliers: Provide sea-worthy wrapping for bundles destined for marine environments, reducing corrosion risk and movement.

Contract Packaging Providers: Offer reliable, fast wrapping services for clients with diverse bundle sizes and materials.

Industrial Manufacturing Plants: Integrate robust orbital wrapping into production lines for large-scale bundle protection and cost savings.

The Pipe Horizontal Orbital Wrapping Machine is engineered for efficient and secure packaging of pipes and cylindrical items. Designed to handle various pipe sizes, it ensures consistent wrapping with adjustable tension and speed settings. Its robust construction and user-friendly operation make it an excellent choice for industries focused on durability and protection during transport.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

Horizontal Orbital Wrapping Mac

The Horizontal Orbital Wrapping Machine for Rod and Bar is designed to provide efficient and secure packaging of long, sl

View DetailsAluminum Horizontal Orbital Wra

Optimize aluminum profile packaging with PLC/HMI-controlled centering rollers and quick material change. Request a quote

View DetailsProfile Horizontal Orbital Wrap

The Profile Horizontal Orbital Wrapping Machine E1400 is designed for efficient and secure wrapping of profiles, rods, an

View DetailsSpiral Orbital Wrapper

The Spiral Orbital Wrapper is a versatile packaging machine designed for wrapping elongated items like pipes, rods, and p

View DetailsHorizontal Ring Stretch Wrapper

The Horizontal Ring Stretch Wrapper is a high-performance packaging machine designed for wrapping long and irregular item

View DetailsHorizontal Stretch Wrapping Mac

The Horizontal Stretch Wrapping Machine for Pallets is designed to securely wrap palletized loads horizontally, ensuring

View DetailsHorizontal Orbital Stretch Wrap

The Horizontal Orbital Stretch Wrapper is engineered for wrapping long and irregularly shaped items with a secure stretch

View DetailsFurniture stretch wrapping mach

The Furniture Stretch Wrapping Machine is designed for securely packaging furniture and bulky items with stretch film. Id

View DetailsEPS Panel Wrapping Machine

The EPS Packing Machine is designed for efficient and secure packaging of expanded polystyrene (EPS) products. Ideal for

View DetailsSix Sided Horizontal Orbital St

The Six-Sided Horizontal Orbital Stretch Wrapper for Board offers complete wrapping coverage for boards and flat items, e

View DetailsPanel Horizontal Orbital Stretc

The Panel Horizontal Orbital Wrapping Machine is specifically designed for wrapping flat panels, boards, and similar larg

View Details