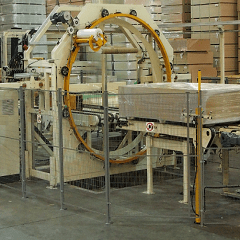

EPS Panel Wrapping Machine

Project Information

The EPS Packing Machine is a specialized solution for efficiently and securely packaging EPS panels, insulation boards, and foam products. Designed for durability and precision, it ensures surface protection, stabilization during wrapping, and streamlined operations for various production needs.

Key Features:

Adjustable-speed belt conveyor with sensors for smooth flow

Stabilizers and rollers for secure, uniform wrapping

Dual presses to prevent shifting and maintain alignment

Side holders to protect packages during wrapping

EPS Panel Wrapping Machine

Automate your EPS panel packaging to eliminate shifting, uneven tension and surface damage—while cutting waste and labor.

The Challenge

- Shifting & Misalignment: Lightweight panels vibrate and move during wrap cycles.

- Uneven Tension: Inconsistent friction leads to over-compression or loose wraps.

- High Throughput: Manual methods bottleneck as demand rises.

- Material Waste: Poor overlap settings drive up film costs.

- Line Integration: Mismatched conveyors and sensors cause stoppages.

- Downtime: Lack of automated diagnostics delays fixes.

- Size Variability: Panels from 1 000–1 250 mm W, 600–1 200 mm H demand quick changeover.

- Safety & Reliability: Film tears and faults must trigger safe stops.

Solution & Benefits

| Feature / Component | Benefit / ROI |

|---|---|

| Dual-Ring, Adjustable-Friction Wheels | Locks panels in place and maintains precise tension—no shifting or over-compression. |

| Inverter-Controlled Ring Speed & Soft Start/Stop | Delivers smooth ramp-up/down (20–60 r/min) and consistent start position—no jerks. |

| Automatic Position Reset & Sensors | Detects panel entry and auto-resets ring—ensures perfect wrap alignment every cycle. |

| Support Rollers & Press-Down Devices | Secures panels from all sides—eliminates vibration and protects edges. |

| Adjustable Conveyor System | Adapts to panel widths 1 000–1 250 mm and syncs speed with wrap cycle—flawless throughput. |

| Material Compatibility | Handles LLDPE film, PE film, knit belt, or paper—flexible protection options. |

| Automatic Tear & Fault Detection | Stops on film tear or roll end—prevents defective wraps and rework. |

| PLC/HMI Wrap Cycle Control | Set ring speed, tension and overlap (20–90%) with an intuitive interface—minimize errors. |

| Quick Changeover & Adjustability | Tool-free adjustments for friction wheels and conveyor—cut setup time. |

| Safety & Diagnostics | Enclosed moving parts, emergency stop and clear HMI alerts—protect operators and uptime. |

| Seamless Line Integration | PLC I/O syncs conveyors and upstream/downstream devices—eliminate bottlenecks. |

| Energy-Efficient Operation | Inverter drives and precise tension reduce power use and film waste—lower operating costs. |

| High Throughput & Reliability | Continuous, stable wrapping at speeds far above manual—maximize ROI. |

Technical Specifications

| Parameter | Specification |

|---|---|

| Model / Product Name | EPS Panel Wrapping Machine |

| Supported Panel Size | W: 1000–1250 mm; H: 600–1200 mm; L: >2000 mm |

| Conveyor Length | Infeed/Outfeed: 3000 mm each (inverter-driven) |

| Ring Speed Range | 20–60 r/min (soft start/stop, position reset) |

| Power Output | ≈ 3.5 kW |

| Power Supply | AC 220 V/380 V, 50/60 Hz, 3-Phase |

| Machine Weight | ≈ 1850 kg |

| Material Compatibility | LLDPE stretch film, PE film, knit belt, paper |

| Film Width | 200–250 mm |

| Mandrel OD/ID | OD: 100–200 mm; ID: 76 mm |

| Support & Press Devices | Two sets of side & top press-down and rollers |

| Sensors & Control | Photoelectric panel & film detectors; PLC/HMI |

| Adjustability | Friction wheels & conveyor speed via inverter |

| Overlap Rate | 20–90% adjustable |

| Safety Features | Enclosed parts, emergency stop, auto-fault stop |

| Installation | Flat hard floor, standard power, minimal foundation |

| Integration Interfaces | PLC I/O for full line sync |

| Operating Environment | Indoor; per EPS handling standards |

| Maintenance & Diagnostics | HMI fault messages; modular access panels |

| Throughput Capability | Continuous automated cycles outperform manual |

Ideal Applications & Industries

- EPS Panel Manufacturing: Prevent edge damage and deformation.

- Construction Materials: Secure insulation and structural boards.

- Furniture & Fixtures: Protect inserts and cushioning panels.

- Appliance & Electronics: Wrap protective inserts consistently.

- 3PL & Contract Packaging: Offer turnkey EPS wrapping services.

- Logistics & Distribution: Streamline dispatch and cut damage claims.

- Modular Building Systems: Maintain panel integrity in prefab builds.

Request a Quote

Ready to boost efficiency and protect your EPS panels? Contact us for custom configurations, drawings and competitive pricing today.

The EPS Packing Machine is designed for efficient and secure packaging of expanded polystyrene (EPS) products. Ideal for delicate and lightweight items, it ensures consistent wrapping or sealing to protect against damage during storage and transportation. With adjustable settings and robust construction, it enhances packaging efficiency and product safety.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

Pipe Horizontal Orbital Wrappin

The Pipe Horizontal Orbital Wrapping Machine is engineered for efficient and secure packaging of pipes and cylindrical it

View DetailsHorizontal Orbital Wrapping Mac

The Horizontal Orbital Wrapping Machine for Rod and Bar is designed to provide efficient and secure packaging of long, sl

View DetailsAluminum Horizontal Orbital Wra

Optimize aluminum profile packaging with PLC/HMI-controlled centering rollers and quick material change. Request a quote

View DetailsProfile Horizontal Orbital Wrap

The Profile Horizontal Orbital Wrapping Machine E1400 is designed for efficient and secure wrapping of profiles, rods, an

View DetailsSpiral Orbital Wrapper

The Spiral Orbital Wrapper is a versatile packaging machine designed for wrapping elongated items like pipes, rods, and p

View DetailsHorizontal Ring Stretch Wrapper

The Horizontal Ring Stretch Wrapper is a high-performance packaging machine designed for wrapping long and irregular item

View DetailsHorizontal Stretch Wrapping Mac

The Horizontal Stretch Wrapping Machine for Pallets is designed to securely wrap palletized loads horizontally, ensuring

View DetailsHorizontal Orbital Stretch Wrap

The Horizontal Orbital Stretch Wrapper is engineered for wrapping long and irregularly shaped items with a secure stretch

View DetailsFurniture stretch wrapping mach

The Furniture Stretch Wrapping Machine is designed for securely packaging furniture and bulky items with stretch film. Id

View DetailsSix Sided Horizontal Orbital St

The Six-Sided Horizontal Orbital Stretch Wrapper for Board offers complete wrapping coverage for boards and flat items, e

View DetailsPanel Horizontal Orbital Stretc

The Panel Horizontal Orbital Wrapping Machine is specifically designed for wrapping flat panels, boards, and similar larg

View Details