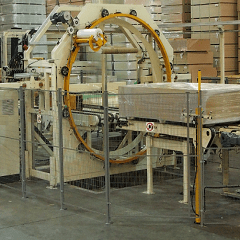

Aluminum Horizontal Orbital Wrapping Machine

Project Information

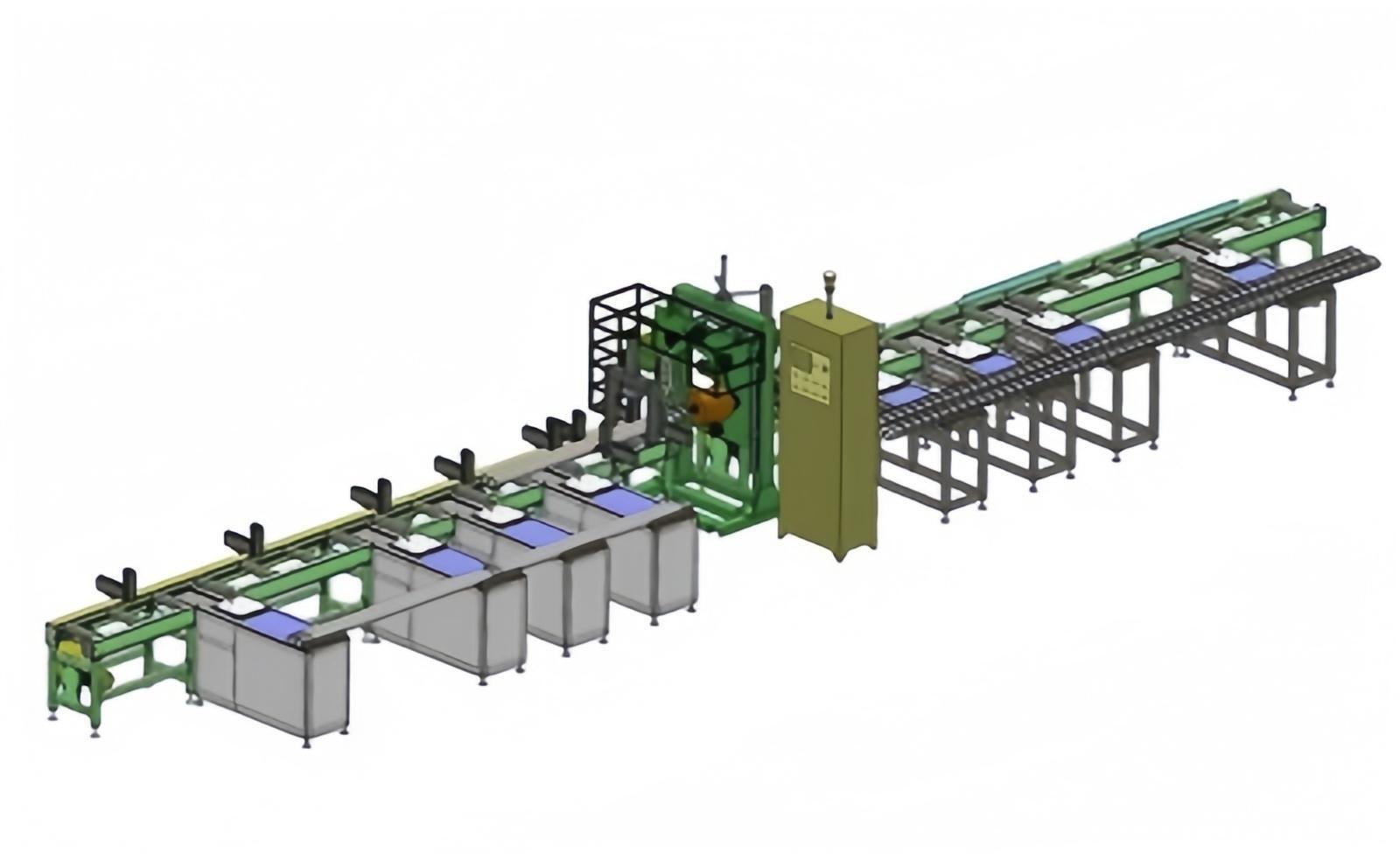

The Aluminum Profile Wrapping Machine is a cutting-edge solution designed for efficient and secure packaging of aluminum profiles, rods, and bars. With advanced automation, customizable features, and seamless integration options, it ensures high-quality packaging while reducing labor and material costs.

Key Features:

PLC/HMI Control: Auto/manual

Ring Speed: 100 RPM

Wrap Settings: Speed & tension

Film Handling: Auto feed & cut

Conveyor: Continuous

Protection: Secure packaging

Aluminum Profile Wrapping Machine

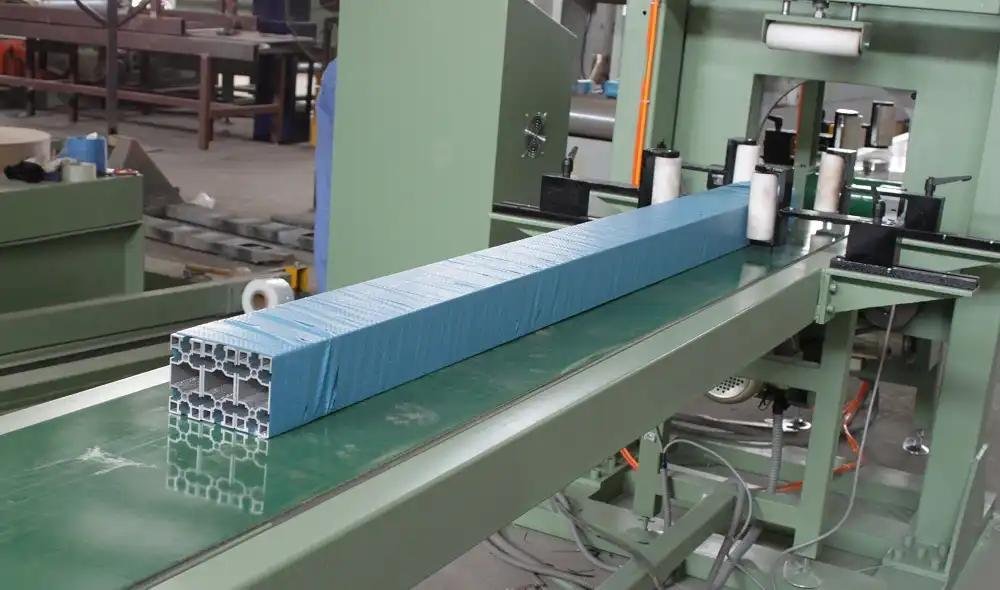

Eliminate inconsistent tension, surface scratches, and high labor costs. Our compact horizontal stretch wrapper handles profiles Ø 300–1500 mm and lengths 2000–8000 mm. Intuitive PLC/HMI control syncs ring and conveyor speeds. Quick-change film frames and adjustable overlap reduce downtime and waste. Soft-surface conveyors protect delicate finishes. Modular design installs on any flat, hard floor—no foundation required. Automatic feeding & cutting minimize manual work. Boost throughput, cut costs, and guarantee damage-free wraps.

Why Decision-Makers Choose It

- Consistent Tension: Precise film control ensures uniform wraps—no rework.

- Surface Protection: PU/PVC conveyors and guides safeguard profiles.

- Labor Savings: Fully automatic cycles free operators for critical tasks.

- Fast Changeovers: Swap PE film, knit belt, or VCI paper in under 1 minute.

- Seamless Integration: PLC interfaces prevent bottlenecks and align with existing lines.

- Energy Efficiency: Inverter drives optimize power use and lower operating costs.

- Safety First: Guardrails, soft start/jog, and automatic alarms protect staff.

Features & ROI

| Feature / Component | Benefit / ROI |

|---|---|

| PLC/HMI-Controlled Programs | Auto/manual modes with intuitive touchscreen—non-technical staff set sequences in seconds, reducing errors. |

| Centering Rollers | Automatically align Ø 300–1500 mm profiles—uniform film application, no scratches. |

| Inverter-Driven Speeds | Match ring (30–60 r/min) and conveyor (2–16 m/min) speeds to profile size—optimize cycle time & energy. |

| Quick-Change Frame | Swap materials in under 60 seconds—minimize downtime and labor costs. |

| Adjustable Overlap (10–90%) | Fine-tune coverage—secure profiles tightly while cutting film use. |

| Soft-Surface Conveyors & Guides | PU/PVC belts and protective rails prevent finish damage. |

| Automatic Feeding & Cutting | Unmanned wrap cycles—film feed, clamp, cut and reset without operator input. |

| Modular, Flat-Floor Installation | No foundations needed—install quickly on existing floors, reducing CAPEX. |

| Error Detection & Alarms | Instant alerts on film tear or misfeed—stop, troubleshoot, and restart fast. |

| Energy-Saving Inverters | Optimize motor power draw—lower utility bills and heat output. |

| Online/Offline Integration | Seamless PLC links to upstream/downstream equipment—eliminate bottlenecks. |

Request a Quote

Ready to transform your aluminum profile packaging? Contact us today with your profile dimensions and throughput goals. We’ll deliver a tailored proposal, technical drawings, and competitive pricing—so you can start saving time, labor, and film costs immediately.

| Parameter | Specification |

|---|---|

| Voltage | AC 380/50 (or your requirement) |

| Power (KW) | 4.8 |

| OD (mm) | 300-1500 |

| Length (mm) | 2000-8000 |

| Weight (Kg) | 100-2500 |

| Packing Material | PE/Stretch film/Knit belt/VCI paper |

| Ring Speed (r/min) | 30-60 |

| Wrapping Speed | 2-16 m/min |

| Overlapping Rate | 10-90% |

Optimize aluminum profile packaging with PLC/HMI-controlled centering rollers and quick material change. Request a quote now!

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

Pipe Horizontal Orbital Wrappin

The Pipe Horizontal Orbital Wrapping Machine is engineered for efficient and secure packaging of pipes and cylindrical it

View DetailsHorizontal Orbital Wrapping Mac

The Horizontal Orbital Wrapping Machine for Rod and Bar is designed to provide efficient and secure packaging of long, sl

View DetailsProfile Horizontal Orbital Wrap

The Profile Horizontal Orbital Wrapping Machine E1400 is designed for efficient and secure wrapping of profiles, rods, an

View DetailsSpiral Orbital Wrapper

The Spiral Orbital Wrapper is a versatile packaging machine designed for wrapping elongated items like pipes, rods, and p

View DetailsHorizontal Ring Stretch Wrapper

The Horizontal Ring Stretch Wrapper is a high-performance packaging machine designed for wrapping long and irregular item

View DetailsHorizontal Stretch Wrapping Mac

The Horizontal Stretch Wrapping Machine for Pallets is designed to securely wrap palletized loads horizontally, ensuring

View DetailsHorizontal Orbital Stretch Wrap

The Horizontal Orbital Stretch Wrapper is engineered for wrapping long and irregularly shaped items with a secure stretch

View DetailsFurniture stretch wrapping mach

The Furniture Stretch Wrapping Machine is designed for securely packaging furniture and bulky items with stretch film. Id

View DetailsEPS Panel Wrapping Machine

The EPS Packing Machine is designed for efficient and secure packaging of expanded polystyrene (EPS) products. Ideal for

View DetailsSix Sided Horizontal Orbital St

The Six-Sided Horizontal Orbital Stretch Wrapper for Board offers complete wrapping coverage for boards and flat items, e

View DetailsPanel Horizontal Orbital Stretc

The Panel Horizontal Orbital Wrapping Machine is specifically designed for wrapping flat panels, boards, and similar larg

View Details