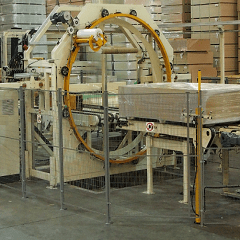

Horizontal Orbital Wrapping Machine for Rod and Bar

Project Information

The Steel Tube Wrapping Machine is a robust and efficient packaging solution designed for steel tubes, bars, sheets, and bundles. It ensures secure and professional wrapping, reducing costs and improving protection during transportation.

Key Features:

Warranty: 5-Year ring reliability

Modes: Manual & semi-automatic

Speed: 1-minute wrap cycle

Protection: Tight film tension

Integration: Plug-and-play automation

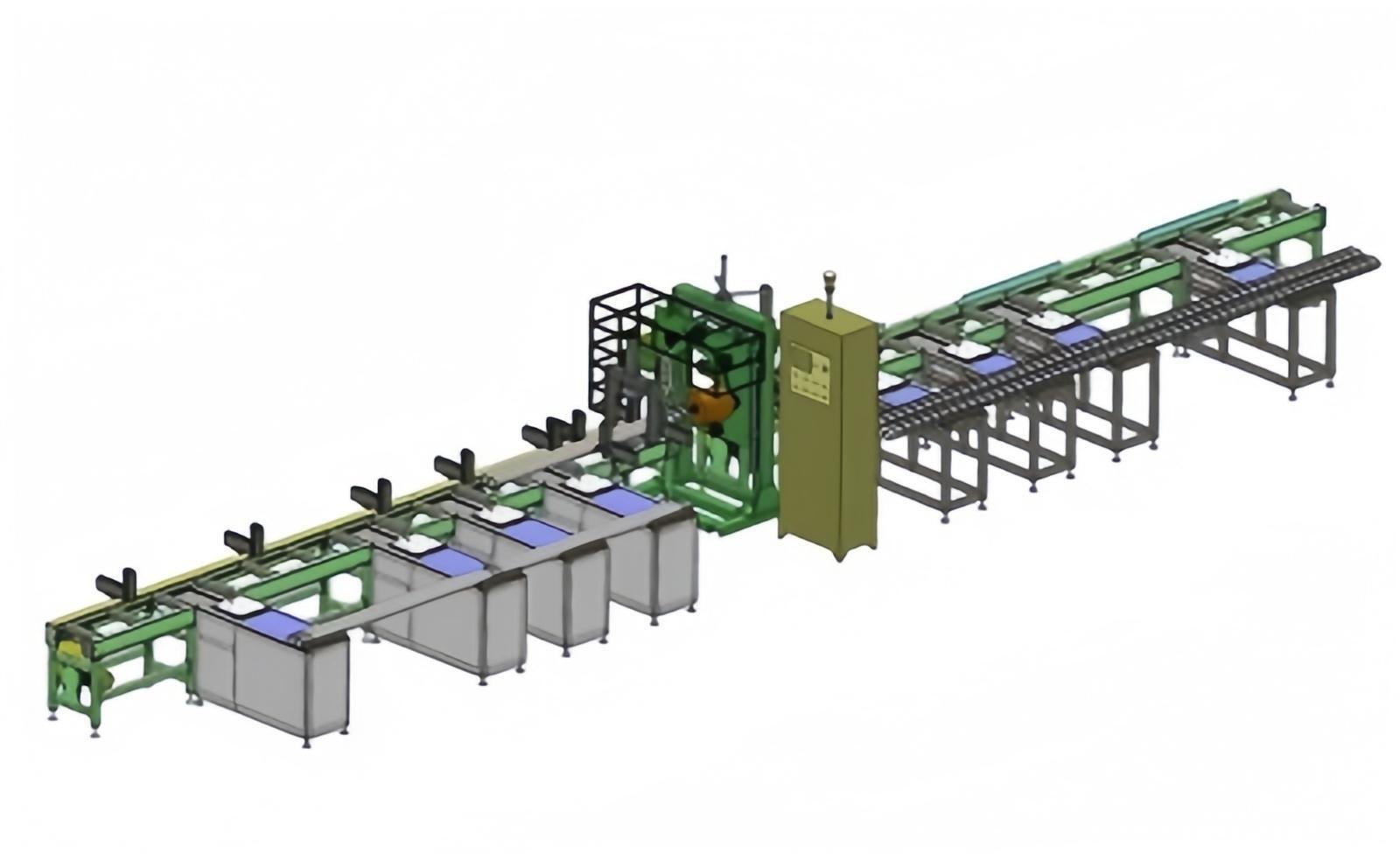

Automated Rod Bundle Wrapping Solution

Manual wrapping causes uneven film tension, misaligned wraps, high labor costs, and surface damage risks. Our Rod Wrapping Machine offers a turnkey automated solution to boost throughput, cut costs, and protect your products.

| Parameter | Specification |

|---|---|

| Product Name / Model | Rod Wrapping Machine |

| Supported Bundle OD | 200–500 mm |

| Bundle Length | 2000–10000 mm |

| Bundle Weight | 2–50 kg (per bundle group) |

| Power Supply | AC 380 V/50-60 Hz (or per requirement) |

| Power (Motor Rating) | 6.8 kW |

| Ring Speed | 30–60 r/min (inverter-controlled) |

| Wrapping Speed | 2–12 m/min |

| Overlap Rate | 20%–90% |

| Tension Control | Automatic via special breaker |

| Material Compatibility | Stretch film, paper, knit belt, VCI paper |

| Infeed/Outfeed Tables | Powered roller tables with rubber-coated rollers; speed adjustable via inverter |

| Positioning System | Pneumatic support rollers and photocell sensing |

| Control System | PLC with HMI touchscreen; automatic alarms and diagnostics display |

| Installation Requirements | Flat, hard ground load ≥1 ton/m²; no foundation required; standard utilities |

| Operation Training | Non-technical personnel can operate within 1 hour |

| Safety Features | Protective guards around moving parts; automatic fault alarms |

| Maintenance & Diagnostics | Clear HMI alerts; easy access to components |

| Effective Throughput | Cycle time optimized (bundle-dependent), enabling higher throughput compared to manual wrapping |

| Integration Options | Online/offline operation; conveyor integration via PLC interfaces |

Challenges

- Unstable Tension: Loose or overly tight film wastes material and increases rework.

- Misalignment: Bundles shift during wrap, causing scratches or dents.

- Labor-Intensive: Requires skilled operators, slowing cycle times and raising costs.

- Line Bottlenecks: Unsynchronized conveyors and wrap cycle lead to downtime.

- Variable Sizes: OD 200–500 mm, lengths 2–10 m demand manual setup changes.

- Complex Maintenance: No fault alerts; longer unplanned stoppages.

- Safety Risks: High-speed moving parts pose hazards without proper guards.

Solution & Benefits

| Key Component | Customer Benefit |

|---|---|

| Pneumatic Support Rollers | Auto-centers bundles for uniform film coverage and surface protection. |

| PLC/HMI Control | One-touch operation; non-technical staff trained in under 1 hour. |

| Inverter Drives | Adjust speed to match production pace, reducing cycle times and energy use. |

| Automatic Tension Adjustment | Consistent film tension minimizes waste and secures loads. |

| Adjustable Overlap | Optimizes protection vs. material use, lowering consumable costs. |

| Powered Roller Tables | Seamless line integration eliminates manual handling delays. |

| Photo-eye Sensing | Detects bundle position for error-free wrap initiation. |

| Safety Guards & Alarms | Enclosed design and immediate alerts protect operators and uptime. |

| Quick Installation | No foundation needed—install on flat floor and start production fast. |

| Multi-Film Compatibility | Supports stretch film, paper, VCI wraps, etc., for various protection needs. |

Wrapping Process Overview

- Feed & Centering: Roller table moves bundle in; pneumatic rollers center it.

- Automated Wrap: PLC starts ring rotation; film carriage applies preset tension and overlap.

- Monitoring & Alerts: Photo-eye confirms position; PLC monitors tension and stops on fault.

- Clamp & Cut: Film is clamped and cut automatically; ring returns to start.

- Discharge & Repeat: Wrapped bundle exits; system resets for the next cycle.

The Horizontal Orbital Wrapping Machine for Rod and Bar is designed to provide efficient and secure packaging of long, slender items like rods and bars. With adjustable settings and durable construction, it ensures consistent wrapping performance. Ideal for industrial applications, it enhances product protection and streamlines packaging processes.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

Pipe Horizontal Orbital Wrappin

The Pipe Horizontal Orbital Wrapping Machine is engineered for efficient and secure packaging of pipes and cylindrical it

View DetailsAluminum Horizontal Orbital Wra

Optimize aluminum profile packaging with PLC/HMI-controlled centering rollers and quick material change. Request a quote

View DetailsProfile Horizontal Orbital Wrap

The Profile Horizontal Orbital Wrapping Machine E1400 is designed for efficient and secure wrapping of profiles, rods, an

View DetailsSpiral Orbital Wrapper

The Spiral Orbital Wrapper is a versatile packaging machine designed for wrapping elongated items like pipes, rods, and p

View DetailsHorizontal Ring Stretch Wrapper

The Horizontal Ring Stretch Wrapper is a high-performance packaging machine designed for wrapping long and irregular item

View DetailsHorizontal Stretch Wrapping Mac

The Horizontal Stretch Wrapping Machine for Pallets is designed to securely wrap palletized loads horizontally, ensuring

View DetailsHorizontal Orbital Stretch Wrap

The Horizontal Orbital Stretch Wrapper is engineered for wrapping long and irregularly shaped items with a secure stretch

View DetailsFurniture stretch wrapping mach

The Furniture Stretch Wrapping Machine is designed for securely packaging furniture and bulky items with stretch film. Id

View DetailsEPS Panel Wrapping Machine

The EPS Packing Machine is designed for efficient and secure packaging of expanded polystyrene (EPS) products. Ideal for

View DetailsSix Sided Horizontal Orbital St

The Six-Sided Horizontal Orbital Stretch Wrapper for Board offers complete wrapping coverage for boards and flat items, e

View DetailsPanel Horizontal Orbital Stretc

The Panel Horizontal Orbital Wrapping Machine is specifically designed for wrapping flat panels, boards, and similar larg

View Details