Eliminate These Costly Steel Coil Packaging Problems

From production delays to damaged shipments, inefficient coil wrapping creates multiple operational headaches. Discover how automated solutions tackle these exact industrial challenges head-on.

Slow Production Throughput

Manual wrapping processes create bottlenecks that delay shipments and limit your facility's output capacity.

Rising Packaging Expenses

Excessive material usage and high labor requirements drive up your operational costs unnecessarily.

Unreliable Damage Protection

Inconsistent wrapping coverage leaves coils vulnerable to corrosion, scratches, and impact damage.

Operational Safety Concerns

Manual handling of heavy industrial coils increases workplace accidents and compliance issues.

Project Overview & Advantages

Explore our specialized capabilities and successful case studies across various manufacturing sectors

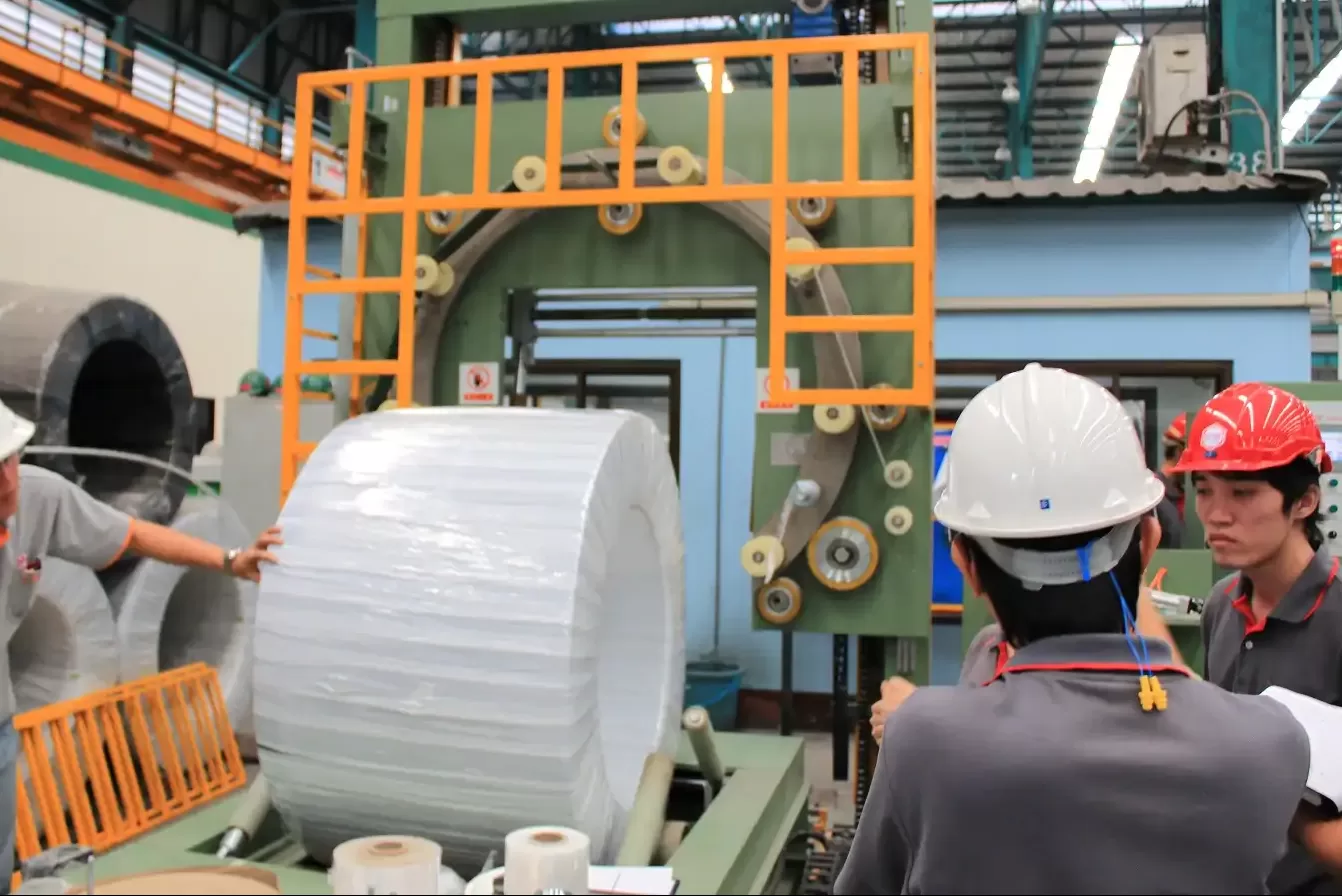

Coil wrapping machine Manufacturing Excellence

Heavy-duty, High Speed Coil wrapping machine manufactured by FHOPEPACK,one of a leading manufacturer of Coil packaging Equipment for different coil shape products, such as steel coil, wire coil, hose, pipe, bearing,tyre...

Steel coil wrapping machine

Discover the ultimate solution for your industrial packaging needs with our Steel Coil Wrapping Machine and advanced Steel Coil Packaging Machinery. Boost efficiency, ensure product safety, and optimize your operations with innovative, reliable equipment designed for high-performance results. Explore the perfect blend of durability and precision for seamless packaging today.

Steel wire wrapping machine

Discover efficient and reliable solutions for your packaging needs with our steel wire wrapping machine and steel wire coil packing machine. Designed to enhance productivity and ensure secure packaging, these advanced machines provide durability and precision for streamlined operations in industrial settings. Optimize your packaging process today with cutting-edge technology.

Hose wrapping machine

Enhance your packaging efficiency with our hose coil wrapping machine and hose packing machine. Engineered for durability and precision, these machines ensure secure and streamlined packaging for hose coils of various sizes. Optimize your workflow and achieve professional-grade results with advanced technology designed to meet your industrial needs.

Copper coil wrapping machine

Streamline your packaging operations with our copper coil wrapping machine and copper coil packing machine. Built for precision and reliability, these machines ensure secure and efficient packaging for copper coils, enhancing product safety and operational efficiency. Upgrade your process with cutting-edge technology designed to meet industrial demands.

Tyre packing machine

Optimize your packaging process with our tyre wrapping machine and tyre packing machine. Designed for durability and precision, these machines provide secure and efficient packaging solutions for tyres of all sizes. Enhance productivity and ensure product protection with advanced technology tailored to your industrial needs.

Cable packing machine

Improve your packaging efficiency with our cable wrapping machine and cable coil packing machine. Designed for reliability and precision, these machines ensure secure and efficient packaging for cable coils of various sizes. Upgrade your operations with advanced technology tailored to meet industrial packaging standards.

Bearing packing machine

Enhance your packaging process with our bearing wrapping machine and bearing packing machine. Engineered for precision and durability, these machines provide secure and efficient packaging solutions for bearings, ensuring product protection and streamlined operations. Optimize your workflow with cutting-edge technology designed for industrial excellence.

Pipe wrapping machine

Boost your efficiency with our advanced pipe coil wrapping machine – the perfect solution for secure, high-speed packing of coils. Designed to handle delicate materials, our plastic pipe coil packing machine ensures superior protection and professional-grade wrapping for optimal transportation. Enhance your operations today!

Advanced Automated Coil Wrapping Systems

Our industrial-grade coil wrapping machines deliver exceptional protection for steel, aluminum, and wire coils through precision-engineered automation. Designed for heavy-duty applications, these systems ensure consistent, secure wrapping that withstands rigorous transportation and storage conditions.

Multi-Material Compatibility: Engineered to handle stretch film, protective paper, and specialty wrapping materials with automatic tension control.

Adaptive Wrapping Technology: Smart sensors automatically adjust to coil dimensions from 500-2500mm diameter, ensuring perfect wrap consistency.

Integrated Safety Systems: Comprehensive protection features including emergency stops, overload protection, and automated safety monitoring.

Faster Wrapping Cycle Times

Reduction in Material Waste

Operational Reliability Rate

Years Average Service Life

European Metal Producer Achieves 300% ROI with Automated Wrapping

Operational Challenge

A prominent European metal manufacturing facility struggled with manual coil wrapping processes that caused production bottlenecks, inconsistent protection quality, and high labor costs affecting their competitive edge in international markets.

Engineering Solution Delivered

We implemented a fully automated coil wrapping system featuring intelligent pattern control and integrated material handling. The solution achieved 28 coils per hour throughput with zero manual intervention, reducing wrapping costs by 60% and eliminating shipping damage claims entirely within six months of operation.

Request Your Custom Solution

SHOWCASE & NEWS

Coil Wrapping Machine FAQ

Expert Answers to Your Industrial Coil Packaging Questions

Our coil wrapping machines are engineered to handle diverse coiled materials including steel coils, aluminum rolls, copper wire, and specialty alloys. Standard configurations accommodate coil weights from 1 to 30 tons, with diameters ranging from 400mm to 2000mm. Custom solutions are available for oversized or non-standard coil specifications. Each machine is calibrated to handle specific material characteristics, ensuring optimal wrapping tension and protection regardless of coil composition or surface finish requirements.

Automated coil wrapping systems typically increase packaging throughput by 300-500% compared to manual methods. Our machines process 15-40 coils per hour with consistent wrap quality, eliminating human variability. The automation reduces labor requirements by up to 75% while ensuring uniform protection across all coils. Advanced features like automatic film cutting and tucking, programmable wrapping patterns, and integrated conveyor systems further streamline operations, minimizing handling time and maximizing production line efficiency.

Our wrapping machines accommodate various protective materials including stretch film, waterproof paper, VCI paper, foam sheets, and composite materials. The systems feature adjustable tension controls and application mechanisms optimized for each material type. Specialized configurations can apply multiple layers of different materials in a single operation, providing comprehensive protection against moisture, corrosion, and physical damage during transportation and storage in diverse environmental conditions.

Yes, our coil wrapping machines are designed for seamless integration with existing production facilities. We engineer custom interfaces for conveyor systems, crane operations, and material handling equipment. The machines support standard industrial communication protocols including Profibus, Ethernet/IP, and Modbus TCP for real-time data exchange with your plant management systems. Our integration specialists work closely with your team to ensure minimal disruption during installation and optimal workflow synchronization post-implementation.

Our coil wrapping machines feature comprehensive safety systems including emergency stop circuits, safety light curtains, interlocked access gates, and overload protection mechanisms. All rotating components are fully guarded, and the control systems include fault detection and automatic shutdown protocols. We comply with international safety standards (CE, UL) and conduct rigorous risk assessments during commissioning. Optional safety enhancements include area scanning systems and remote monitoring for hazardous environment operations.

Most clients achieve complete ROI within 12-24 months through multiple cost-saving channels. Significant savings come from reduced labor costs (typically 2-3 operators replaced by automated system), decreased material waste (15-30% film savings), and minimized product damage during transit (up to 90% reduction). Additional benefits include increased throughput capacity, improved workplace safety, and enhanced customer satisfaction through consistent packaging quality. We provide detailed ROI analysis during consultation based on your specific operational parameters.

Our Clients Around The World

We are honored to serve outstanding enterprises worldwide, establishing long-term stable partnerships. Below are some of our trusted partners who have chosen our manufacturing solutions.

Ready to Start Your Next Manufacturing Project?

Impressed by our projects? If you have similar requirements or want to discuss your project ideas, contact our expert team immediately for a free initial consultation.

Contact Our Experts