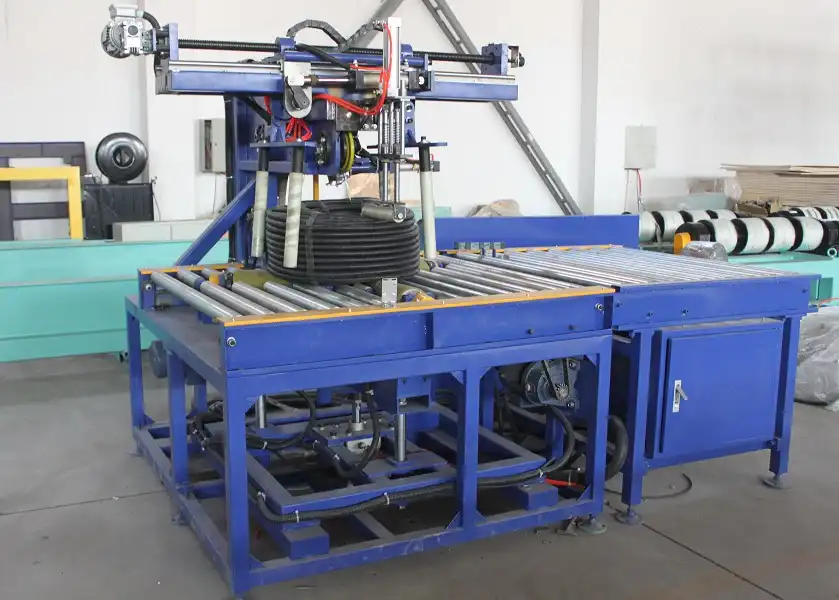

Bearing packing line

Project Information

Fhopepack specializes in custom automatic bearing packaging solutions designed to meet diverse industry requirements. With a focus on advanced technology, precision, and durability, Fhopepack offers high-quality machinery to streamline packaging processes, ensuring product safety during shipping and handling.

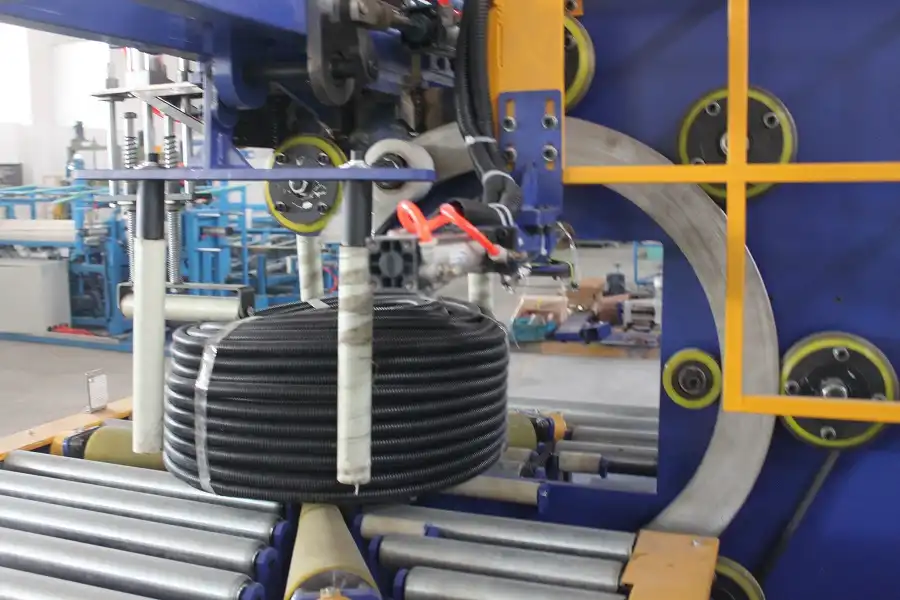

Wrapping Station

Top-brand components for reliable, long-lasting performance

Manual alignment for pinpoint positioning

Adjustable speed, overlap, tension, and friction for any wrap material

Support rollers, guards, and soft start/stop for safer operation

Indicator lights & separate electrical cabinet for quick maintenance

Manual or semi-auto bearing packaging demands multiple operators, yields uneven wraps, and wastes material. Wuxi BuHui’s Automatic Online Bearing Packing Machine automates positioning, transfer, tensioning, and overlap—delivering fast, consistent protection with minimal labor.

The Challenge

- Labor & Inconsistency: Multiple operators and imprecise wraps risk damage and uneven protection.

- Material Waste: Inaccurate overlap and cut-off inflate film and tape costs.

- Changeover Delays: Varying bearing sizes require manual setup—extends downtime.

- Flow Disruptions: Manual transfers stall production and increase handling risks.

- Maintenance Delays: No real-time fault alarms or easy component access slows troubleshooting.

- Safety Risks: Handling heavy bearings without reliable conveyors, soft start/stop, and guards increases accidents.

- Customization Needs: Flexible two-layer options demand automated control.

The Solution

| Feature | Benefit & ROI |

|---|---|

| PLC/HMI with Program Storage | Store 6 bearing profiles—one-touch changeovers and consistent results. |

| Automatic ID-Based Positioning | Centers each bearing for uniform wrapping—eliminates manual misalignment. |

| Infeed/Outfeed Conveyors | Automates transfer (manual or motorized)—reduces handling labor and speeds flow. |

| Adjustable Tension & Overlap (20%–90%) | Fine-tune wrap tightness and overlap—secures bearings with minimal waste. |

| Material Flexibility | Supports film, paper, woven/knit belts, PVC, etc.—match protection to budget. |

| Two-Layer Packaging Capability | Add secondary layer (paper/belt) over film in one cycle—enhances protection. |

| Soft Start/Stop & Real-Time Alarms | Smooth cycles and immediate fault alerts—protects equipment and cuts downtime. |

| Variable Speed Control (20–90 RPM) | Adjust cycle time (~40–50 sec) to balance throughput and wrap quality. |

| Automatic Cut-Off System | Precise cuts after each wrap—prevents waste and ensures clean edges. |

| Line Integration | Interfaces for upstream conveyors—synchronizes flow and avoids bottlenecks. |

| Fault Monitoring & Diagnostics | Sensors detect misfeeds or jams; HMI displays fault codes for quick fixes. |

| Safety Guards & Maintenance Access | Guardrails, E-stop, and quick-access panels ensure safe, fast servicing. |

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | Automatic Online Bearing Packing Machine |

| ID Range | 200–500 mm |

| OD Range | 300–800 mm |

| Width Range | 20–200 mm |

| Weight Range | 20–500 kg |

| Power | AC 380 V, 50 Hz, 3-phase |

The bearing packing line is a comprehensive solution for efficient and reliable bearing packaging. It automates processes like wrapping, sealing, and stacking, ensuring optimal protection against dust and damage. Designed for industrial-scale operations, it enhances productivity, reduces labor costs, and delivers consistent, high-quality packaging results.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

Bearing packing machine FPB-400

The FPB-400 bearing packing machine offers a streamlined solution for secure and efficient bearing packaging. Designed fo

View DetailsBearing packing machine

A bearing packing machine streamlines the packaging of bearings by utilizing automated systems for accuracy and speed. It

View DetailsBearing wrapping machine

The bearing wrapping machine is designed to provide efficient and protective packaging for bearings. It ensures a secure

View DetailsBig size bearing packing machin

The big-size bearing packing machine is a specialized solution for packaging large bearings with precision and care. It o

View DetailsBearing bag packing machine

The bearing bag packing machine provides an efficient solution for sealing bearings in protective bags. It ensures secure

View Details