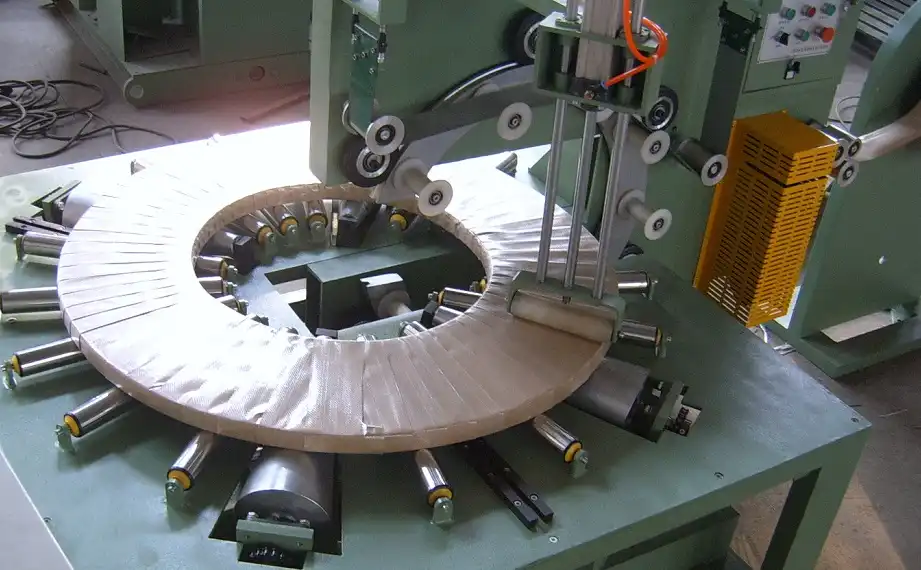

Bearing wrapping machine

Project Information

The bearing wrapping and packing machine is a specialized solution for packaging large bearings and axletrees, offering enhanced protection, efficiency, and cost savings. Its automation capabilities and advanced controls make it ideal for industries requiring consistent and reliable packaging solutions.

Advantages

Secures bearings with tight, uniform wraps to prevent damage in transit

Automates packaging for faster, consistent throughput

Speeds operations and cuts labor to lower overall packaging costs

Manual packaging of large bearings is labor-intensive, inconsistent, and wasteful. Wuxi BuHui’s FPB-300 Bearing Wrapping Machine automates ID-based positioning, tension control, and two-layer wrapping—delivering fast, uniform protection with minimal labor.

The Challenge

- High Labor & Risk: Multiple operators handle heavy bearings, causing strain and inefficiency.

- Uneven Wraps: Manual centering and tension lead to loose or over-tight wraps.

- Material Waste: Imprecise overlap and cuts drive up film and paper costs.

- Slow Changeovers: Varying sizes demand lengthy manual adjustments.

- Flow Disruptions: Manual transfers stall production and increase downtime.

- Safety & Maintenance: No automatic fault detection or easy access prolongs downtime.

The Solution

| Feature | Benefit & ROI |

|---|---|

| PLC/HMI with 6 Programs | Instant recall of wrap recipes—cuts changeover time and ensures consistency. |

| Automatic ID-Based Positioning | Centers bearings precisely—eliminates miswraps and damage risk. |

| Motorized Conveyors | Automates feeding and discharge—reduces manual handling and speeds flow. |

| Two-Layer Wrap | Combines film plus paper/belt in one cycle—enhances protection with minimal steps. |

| Adjustable Tension & Overlap (20%–80%) | Secures bearings tightly while minimizing material use. |

| Soft Start/Stop & Alarms | Smooth operation and real-time alerts—protects equipment and reduces downtime. |

| Flexible Manual/Auto Modes | Adapts to varying production needs—maximizes uptime and operator control. |

Technical Specifications

| Parameter | Specification |

|---|---|

| Machine Model | FPB-300 Bearing Wrapping Machine |

| Bearing ID Range | 300–900 mm |

| Bearing OD Range | 600–1200 mm |

| Width Range | 20–300 mm |

| Weight Range | 10–500 kg |

| Power Supply | AC 380V, 50Hz, 3-phase |

| Power Consumption | 2.5 kW |

| Wrapping Speed | 40–50 sec/piece |

| Ring Speed | 30–70 RPM |

| Overlap Rate | 20%–80% |

| Packing Materials | Film, paper, woven belt, knit belt, PVC, etc. |

| Program Storage | Up to 6 sets |

| Conveyors | Motorized infeed/outfeed |

| Tension Control | Adjustable via inverter |

| Cut-Off System | Automatic after wrap |

| Control Interface | PLC/HMI touchscreen or keypad |

| Safety Features | Guardrails, E-stop, fault detection |

| Construction | Heavy-duty frame |

| Integration | Upstream/outbound conveyor interfaces |

| Maintenance Access | Quick-open panels |

Request Your Customized FPB-300 Solution

Contact Wuxi BuHui with your bearing specs to configure a turnkey wrapping system that boosts throughput, cuts labor, and delivers uniform, high-quality protection.

The bearing wrapping machine is designed to provide efficient and protective packaging for bearings. It ensures a secure wrap, safeguarding bearings from external elements like dust and moisture. With its automated operation and user-friendly design, it enhances productivity while maintaining high-quality packaging standards for industrial applications.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

Bearing packing machine FPB-400

The FPB-400 bearing packing machine offers a streamlined solution for secure and efficient bearing packaging. Designed fo

View DetailsBearing packing machine

A bearing packing machine streamlines the packaging of bearings by utilizing automated systems for accuracy and speed. It

View DetailsBearing packing line

The bearing packing line is a comprehensive solution for efficient and reliable bearing packaging. It automates processes

View DetailsBig size bearing packing machin

The big-size bearing packing machine is a specialized solution for packaging large bearings with precision and care. It o

View DetailsBearing bag packing machine

The bearing bag packing machine provides an efficient solution for sealing bearings in protective bags. It ensures secure

View Details