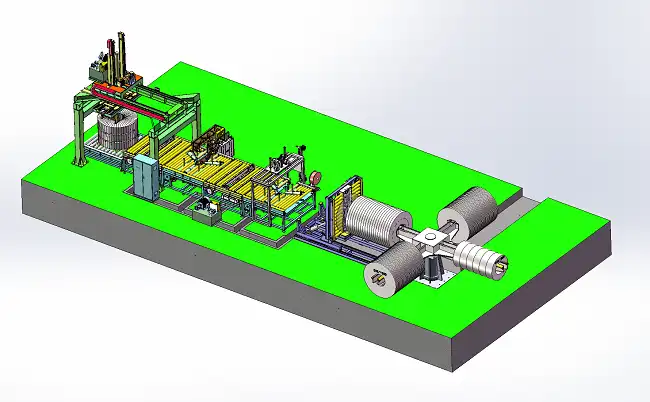

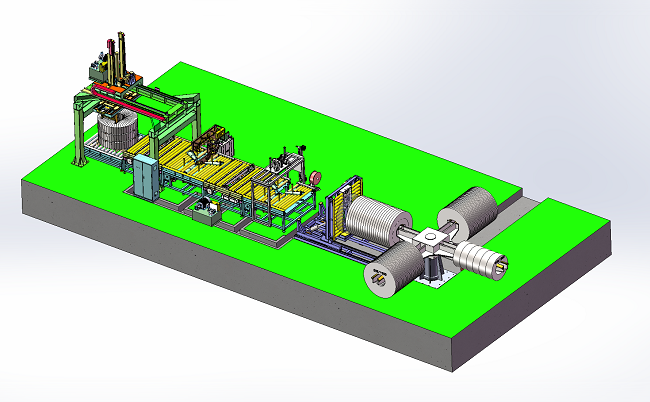

Copper coil packing line

Project Information

Copper tube coil packing machines are specialized equipment designed to wrap and secure copper tubing coils with protective materials such as paper, woven fabric, PE, or stretch film. These machines are widely used in the manufacturing and distribution sectors to ensure that copper tubing remains safe from damage and contamination during transportation and storage.

Key Features:

Horizontal feeding for faster, hassle-free coil loading

Versatile material support to ensure optimal protection

Inverter-driven controls for precise wrap speed and tension

The copper coil packing line is a specialized system for efficiently packaging copper coils. It offers automated processes like wrapping, strapping, and sealing to ensure secure and damage-free handling. Designed for industrial demands, it improves productivity, minimizes material waste, and provides reliable protection during storage or transportation.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

Copper coil packing machine

The copper coil packing machine offers streamlined and secure wrapping solutions for copper coils, ensuring protection fr

View DetailsFPC-300 Copper coil wrapper

The FPC-300 Copper Coil Wrapper is a specialized packaging machine designed for efficient and secure wrapping of copper c

View DetailsFPC-200 Copper coil wrapper

The FPC-200 Copper Coil Wrapper provides robust and efficient wrapping solutions for copper coils, enhancing protection a

View DetailsCopper Tube Coil

Copper tube coils are essential for heat transfer and fluid systems, offering superior thermal conductivity and resistanc

View Details