Copper Tube Coil

Project Information

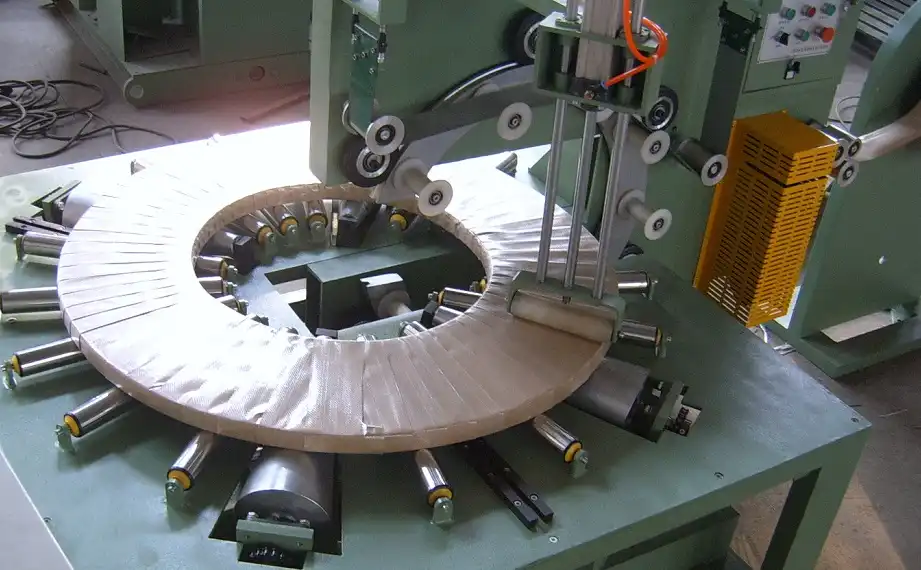

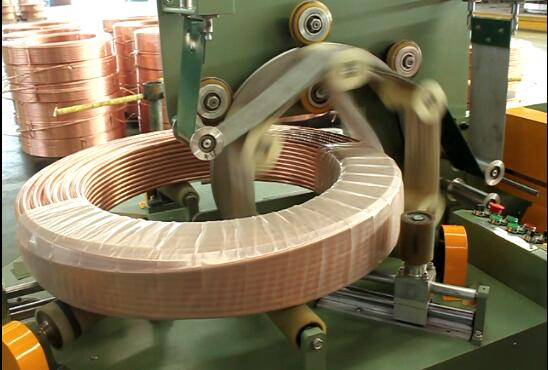

Copper tube coil packing machines are specialized equipment designed to wrap and secure copper tubing coils with protective materials such as paper, woven fabric, PE, or stretch film. These machines are widely used in the manufacturing and distribution sectors to ensure that copper tubing remains safe from damage and contamination during transportation and storage.

Key Features:

Horizontal feeding for effortless coil loading

Versatile material compatibility

Inverter-controlled ring and tension for flexible wrapping

Secure fixation with tape or fasteners

Automatic conveyor for smooth transfer

Protect copper tube and metal coils from damage, dust, and moisture with an efficient horizontal wrapping solution. The Copper Tube Coil Packing Machine handles 50–300 kg coils (10–300 mm wide) and delivers uniform, tight wraps in 25–45 seconds each.

The Challenge

- Multiple Coil Types: One machine for copper, steel, wire or cable coils—cuts footprint and cost.

- Consistent Protection: Uniform tension and overlap seal out contaminants and prevent deformation.

- Fast Changeovers: Adjustable for OD 600–1200 mm & ID 500–800 mm to keep throughput at 25–45 sec/coil.

- Operator-Friendly: Intuitive controls, PU surfaces and alarm indicators minimize training and downtime.

- Material Efficiency: Optimize overlap (20–90 %) and tension to reduce film or belt waste.

- Seamless Integration: Auto conveyor hookup for smooth transfer to stackers.

- High Uptime: Premium components and clear faults keep production running.

Features & Benefits

| Feature | Benefit & ROI |

|---|---|

| Horizontal Wrapping Design | One machine wraps all coil types—reduces capex and saves floor space. |

| Inverter-Controlled Speeds | Fine-tune ring (20–110 RPM) and roller (2–4 m/min) speeds for perfect wraps. |

| Adjustable Overlap (20 %–90 %) | Seal out dust/moisture and minimize material use to lower costs. |

| Tension Control | Maintain uniform tension to protect coil shape and finish. |

| PU-Covered Surfaces | Prevent abrasion and preserve coil quality. |

| Auto Trouble Alarms | Instant fault alerts speed troubleshooting and boost uptime. |

| Easy Operation & Maintenance | Non-technical staff run and maintain with minimal training. |

| Conveyor Integration | Hands-free transfer of wrapped coils cuts manual handling. |

| Auto Material Cut-Off | Precise end-of-wrap finish reduces labor. |

| Quick Reset System | Fast ring repositioning slashes changeover time. |

| Premium Components | Siemens, Autonics, Delta, AIRTEC parts ensure reliability and long life. |

| Wide Size Range | OD 600–1200 mm, ID 500–800 mm, width 10–300 mm, weight 50–300 kg in one setup. |

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | Copper Tube Coil Packing Machine |

| Coil Weight | 50–300 kg |

| Width Range | 10–300 mm |

| ID Range | 500–800 mm |

| OD Range | 600–1200 mm |

| Wrap Cycle | 25–45 sec/coil |

| Ring Speed | 20–110 RPM (inverter) |

| Roller Speed | 2–4 m/min (inverter) |

| Overlap | 20 %–90 % |

| Power | 380 V, 50/60 Hz, 3-phase |

| Air | 5–8 kgf/cm² |

| Materials | Woven belt, paper, PE, stretch film (ID 50 mm, OD 150–400 mm, W 90 mm) |

| Controls | PLC, HMI, inverter, sensors, encoder, pneumatics |

| Safety | Guardrails, overload protection, auto-stop on fault |

| Mode | Automatic |

| Customization | Configure conveyor length, ring height, wrap parameters, integration |

Ideal for

- Copper tube producers and metal coil packagers

- Service providers offering versatile wrapping

- Logistics & warehousing for secure stacking

- OEMs & integrators building automated lines

- Maintenance teams repackaging replacement coils

Why Wuxi BuHui?

Wuxi BuHui’s Copper Tube Coil Packing Machine pairs inverter-controlled flexibility, premium components, and easy operation. It delivers uniform, protective wraps at 25–45 sec/coil, minimizes material waste, and integrates seamlessly into your line—boosting throughput and safeguarding coil quality.

Request Your Quote

Share your coil specs and integration needs with Wuxi BuHui to get a tailored wrapping solution that maximizes efficiency and protects your products.

Copper tube coils are essential for heat transfer and fluid systems, offering superior thermal conductivity and resistance to corrosion. Widely used in HVAC, refrigeration, and industrial applications, they ensure efficiency and durability. Available in various specifications, these coils are designed for reliable performance in demanding environments, meeting diverse operational needs.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

Copper coil packing machine

The copper coil packing machine offers streamlined and secure wrapping solutions for copper coils, ensuring protection fr

View DetailsFPC-300 Copper coil wrapper

The FPC-300 Copper Coil Wrapper is a specialized packaging machine designed for efficient and secure wrapping of copper c

View DetailsFPC-200 Copper coil wrapper

The FPC-200 Copper Coil Wrapper provides robust and efficient wrapping solutions for copper coils, enhancing protection a

View DetailsCopper coil packing line

The copper coil packing line is a specialized system for efficiently packaging copper coils. It offers automated processe

View Details