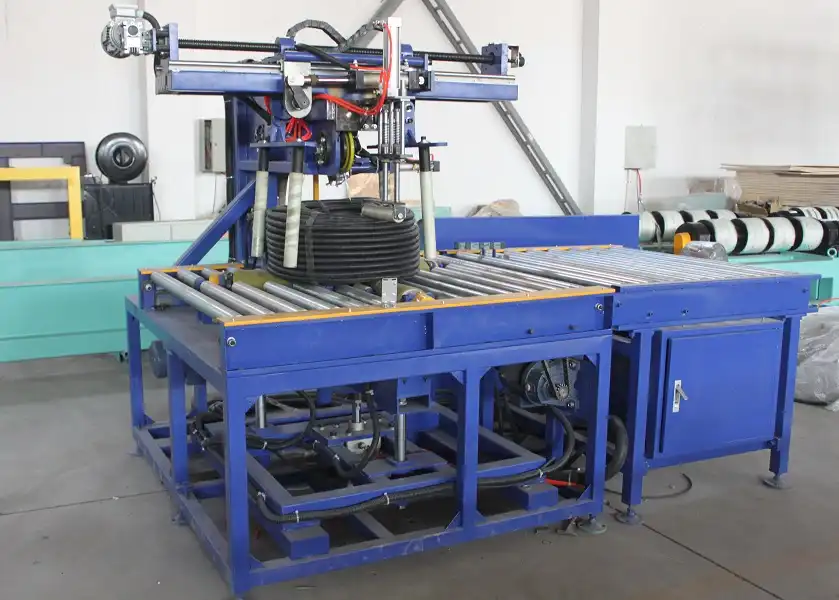

Automatic hose wrapper FPCA-300H

Project Information

The FPH Series Hose Wrapping Machine by Fhope Machinery is an advanced, automated solution for efficient and reliable hose packaging. Designed for industries like plastic and rubber pipes, metallurgy, and more, this machine offers superior moisture-proof and dust-proof capabilities, saving labor and materials while delivering excellent packaging results. With adjustable features and online coiling capabilities, it meets diverse industrial needs and enhances operational efficiency.

Key Features:

Moisture & Dust Protection

High-Efficiency Packaging

Adjustable Tension & Coverage

Broad Wrapping Range (pipes, hoses, tires, belts)

Inline Coiling Integration

Streamline hose and pipe coil packaging with Wuxi BuHui’s Automatic Hose Coil Packing Machine (FPCA-300). A single operator can load, wrap, and unload inline, ensuring consistent tension and overlap while reducing labor and setup time.

The Challenge

- Labor intensive: Multiple operators required, driving up costs and complexity.

- Inconsistent quality: Uneven tension and overlap lead to waste and rework.

- Integration issues: Separate coiler, downender, wrapping, and strapping stations create bottlenecks.

- Lengthy setups: Changing coil sizes demands time-consuming adjustments.

- Safety risks: Manual handling strains workers and increases injury potential.

- Material waste: Loose tails and manual cutting add scrap and extra steps.

- Capacity constraints: Lack of inline automation limits throughput.

The Solution

FPCA-300 integrates conveyors, centering, two-layer wrapping, automatic tail management and stacking under PLC/HMI control. Seamlessly link to upstream coiler, downender, and strapping lines for a turnkey, high-throughput workflow.

| Feature | Benefit / ROI |

|---|---|

| PLC/HMI Control with Stored Coil Profiles | Recall settings for varied coil sizes (ID Φ300–1000 mm, OD Φ600–1200 mm, width 150–300 mm), slashing setup time and errors. |

| Horizontal Inline Conveyor Integration | Automate infeed/outfeed to coiler, downender, stacking—one operator manages end-to-end safely. |

| Centering Device with Adjustable Rollers | Ensure uniform wrap by precisely aligning coils of any size. |

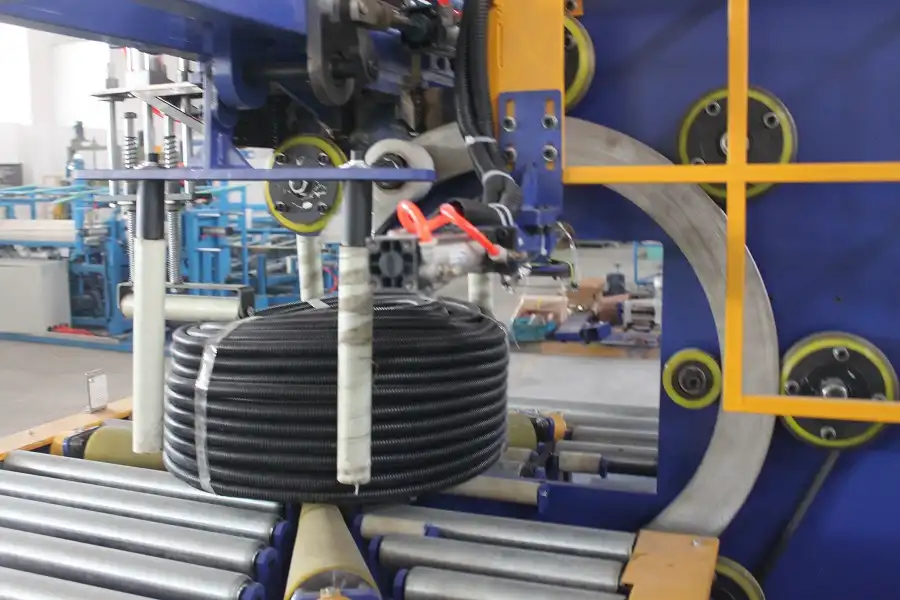

| Two-Layer Wrapping (Inner Stretch Film + Outer Paper/HDPE/Woven) | Deliver robust dust and moisture protection with a clean “no-tail” finish. |

| Automatic Film/Material Feeder, Clamper & Cutter | Eliminate manual tail tap—feed, clamp, and cut material automatically to reduce waste and cycle time. |

| Inverter-Adjustable Ring & Roller Speeds | Fine-tune tension and overlap for optimal wrap quality across materials. |

| Adjustable Tension & Overlap (10–90%) | Secure coils tightly while minimizing material usage. |

| Supportive Rollers Lifting Coil for Wrapping | PU-covered rollers protect surfaces and simplify loading. |

| Automatic Coil Positioning (Front & Back) | Precisely stop coils at wrap and outfeed positions, reducing manual intervention. |

| Indicator Alarms & Real-Time Monitoring | Alert operators to deviations instantly, maximizing uptime. |

| Soft Start/Stop and Ring Reset | Protect equipment and personnel with smooth operation and reliable positioning. |

| Stacking Conveyor for Finished Coils | Automatically transfer wrapped coils to the stacking area, reducing labor. |

| Wide Material Compatibility | Supports a full range of films and outer layers to fit varied coil specs. |

| Seamless Integration | Connects coiler, downender, and strapping line for an end-to-end inline solution. |

| Customizable Solutions | Tune parameters and options to meet unique production requirements. |

Technical Specifications

| Specification | Details |

|---|---|

| Machine Model | FPCA-300 |

| Coil ID Range | Φ300–1000 mm |

| Coil OD Range | Φ600–1200 mm |

| Coil Width Range | 150–300 mm |

| Coil Weight Range | 10–100 kg |

| Wrapping Speed | 25–35 sec/coil |

| Max Ring Speed | Up to 100 r/min |

| Power Supply | 380 V, 60 Hz, 3-phase |

| Power Consumption | ~3.5 kW |

| Packing Materials | Stretch film & paper/HDPE/woven options |

| Overlap Rate | 10–90 % |

| Control System | PLC & HMI touchscreen, stored profiles |

| Conveyor & Stacking | Inline conveyors, customizable length |

| Centering Device | Adjustable, cylinder-driven rollers |

| Supportive Rollers | PU-covered lifting rollers |

| Working Height | ~880–890 mm adjustable |

| Safety Devices | Guardrails, alarms, soft start/stop |

| Environmental Conditions | Standard environments (consult for extremes) |

| Customization Options | Special conveyors, handling, coil specs |

Ideal Applications & Industries

- Corrugated Hose Manufacturers: Inline coil wrapping with minimal intervention.

- PVC/PE Pipe Extrusion Lines: Immediate, consistent protection post-extrusion.

- Industrial Hose Producers: Efficient horizontal packaging for varied diameters.

- Packaging Facilities: Flexible handling of diverse coil sizes and materials.

- High-Mix, Single-Operator Lines: Rapid changeovers via stored PLC profiles.

- Safety-Critical Environments: Automated handling reduces injury risk.

Why Wuxi BuHui?

Our turnkey inline solution combines advanced PLC/HMI control, ergonomic design, and seamless integration to reduce labor, minimize waste, and boost throughput—delivering consistent, high-quality packaging for modern hose and pipe production.

Request a Quote

Ready to optimize your coil packaging? Contact Wuxi BuHui today for a customized solution that enhances efficiency, safety, and reliability.

The automatic hose wrapper streamlines the packaging process by providing fast, consistent wrapping for hoses of various sizes. Designed to enhance efficiency, it minimizes handling time and protects products during transit. This machine is versatile and easy to operate, making it a valuable addition to any industrial packaging setup.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

PE Corrugated Hose Coil Wrappin

The FPCA-200H coil wrapper offers reliable, automated wrapping for steel and aluminum coils, enhancing both protection an

View DetailsAutomatic Pipe Coiling and Stra

The hose coiling and strapping machine streamlines the process of coiling and packaging hoses with precision and speed. D

View DetailsAutomatic Hose Coil Packing Mac

The automatic hose packing line integrates coiling, strapping, and wrapping into a fully automated process, ensuring spee

View DetailsCorrugated hose wrappinging mac

The corrugated hose packing machine streamlines the process of wrapping corrugated hoses, providing durable and secure pa

View DetailsHose Coil wrapping machinery FP

The FPH-500 Hose Coil Wrapping Machine provides streamlined wrapping for hose coils, ensuring consistent protection and s

View DetailsHose Coil wrapping machinery FP

The FPH-400 Hose Coil Wrapping Machine offers streamlined packaging for hose coils, improving efficiency and safeguarding

View DetailsHose wrapping machine FPH-300

The FPH-300 Hose Wrapping Machine offers reliable, high-speed wrapping for hoses of different sizes, ensuring enhanced pr

View DetailsHose Coil packing machinery FPH

The FPH-200 Hose Coil Packing Machinery is a high-performance packaging solution tailored for hose coils. Equipped with a

View DetailsHose film wrapper FPS-300H

A hose film wrapper is an efficient packaging solution designed to wrap hoses tightly with protective film, safeguarding

View DetailsHose Wrap Machine

The hose wrap machine is an advanced packaging tool engineered for wrapping hoses with precision and speed. It provides c

View Details