Hose Coil wrapping machinery FPH-400

Project Information

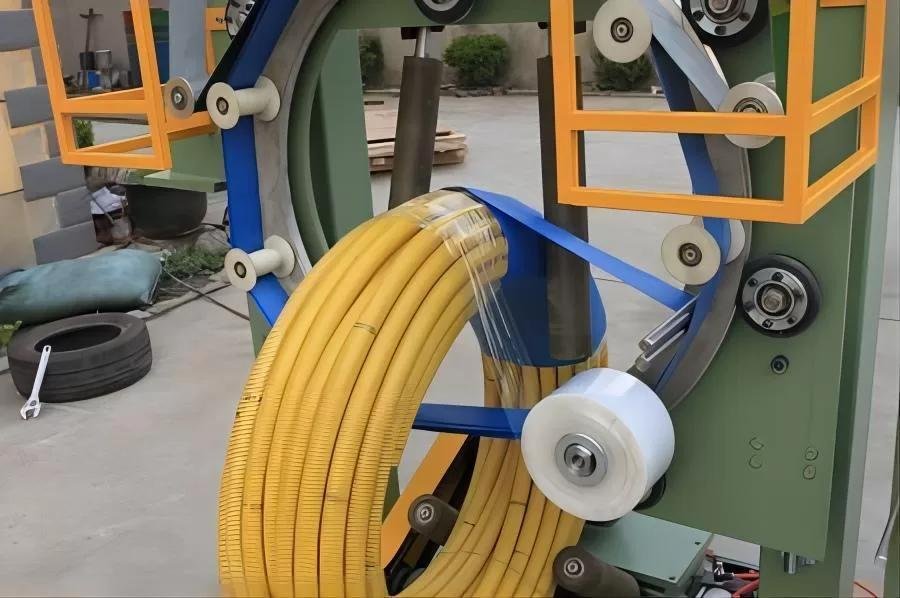

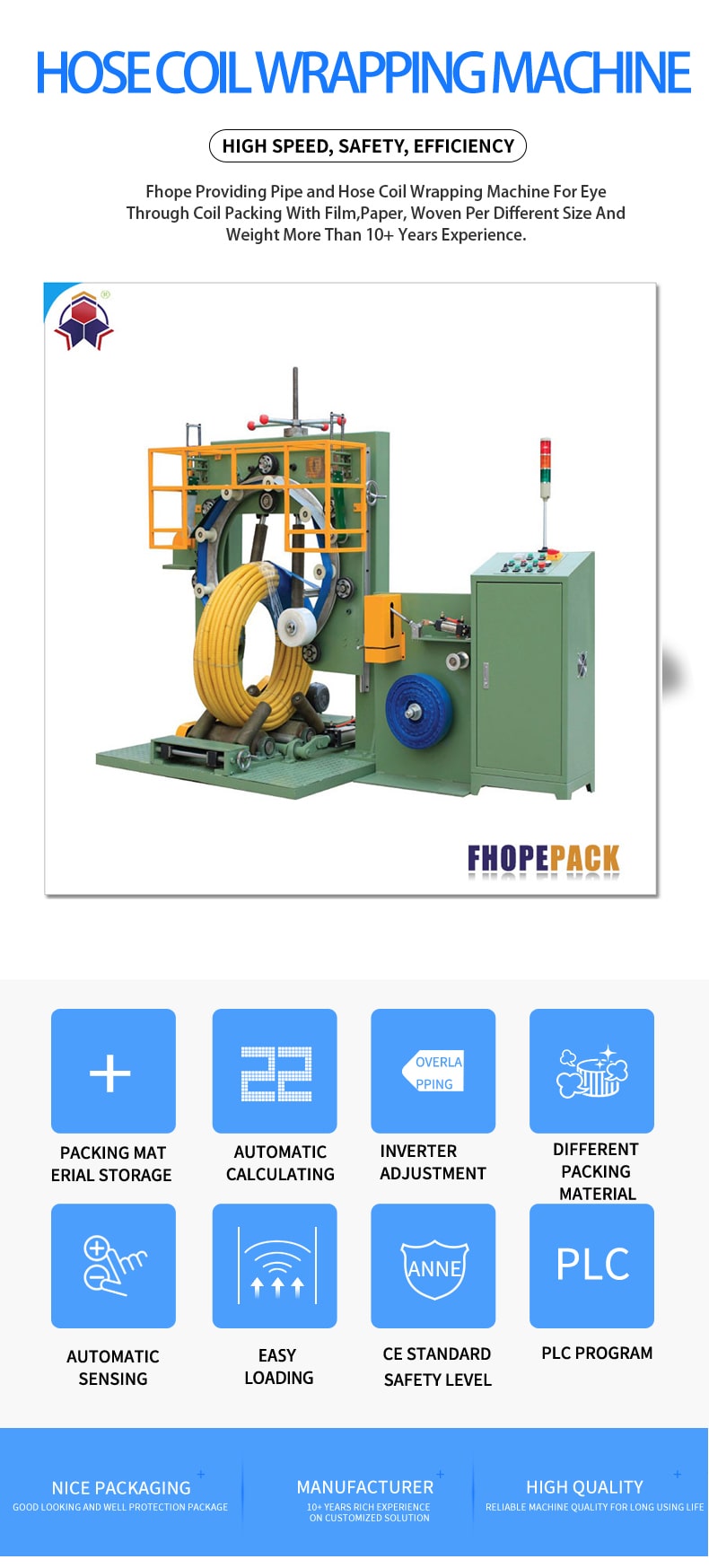

The FPH-400 is a semi-automatic and automatic hose winding packaging machine, tailored for various coiled materials like plastic pipes, rubber hoses, and tires. Designed by Fhope, it ensures efficiency, safety, and enhanced product integrity during transportation, delivering a professional, polished appearance.

Key Features:

Versatile: Rings & shapes

Modes: Manual/Auto, adjustable speed

Customizable: Overlap & materials

Safe: Guards, soft start, tension control

Eliminate moisture, dust and wrap inconsistencies in your hose & plastic pipe coil packaging. Wuxi BuHui’s FPH-400W delivers high-speed vertical-eye wrapping for coil IDs Φ300–Φ1250 mm and ODs up to Φ1500 mm. Adjustable overlap, precise tension control, inverter-driven speed, and multi-material compatibility ensure uniform, protective wraps. Safety guardrails, soft start/stop, and reset-to-origin simplify operation. Boost throughput, cut waste, and protect coil quality with the FPH-400W.

The Challenge: Common Coil Packaging Pain Points

- Environmental Protection: Keep coils dry and clean in storage and transit.

- Wide Size Range: Handle IDs Φ300–Φ1250 mm, ODs up to Φ1500 mm, widths 150–400 mm, weights 10–100 kg in one machine.

- Labor & Cycle Time: Reduce manual handling and hit 20–30 sec/cycle targets.

- Consistent Wraps: Avoid loose or over-tight wraps that damage coils or waste film.

- Safe, Smooth Operation: Prevent sudden stops, coil shifts, and ergonomic strain.

- Flexible Integration: Switch between manual/auto modes; reset to origin for seamless line sync.

- Custom Requirements: Adapt to unique layouts, materials, and coil specs.

The Solution: FPH-400W Features & Benefits

| Feature | Benefit & ROI |

|---|---|

| Vertical-Eye Wrapping | Ensures full-circumference coverage for secure, stable bundles. |

| Adjustable Overlap (20%–90%) | Fine-tunes wrap density to minimize film usage and cost. |

| Tension & Brake Control | Maintains optimal tightness to prevent coil deformation. |

| Inverter-Driven Speed | Optimizes cycle time (30–55 sec) to match production rates. |

| Manual/Auto Modes | Offers operator control for special runs and full automation for volume jobs. |

| Soft Start/Stop & Reset-to-Origin | Protects coil surfaces and streamlines workflow. |

| Multi-Material Compatibility | Use stretch film, paper, woven or HDPE to suit protection needs. |

| Easy Load/Unload | Reduces labor strain and speeds up packaging cycles. |

| 20–30 sec Packaging Speed | Meets high throughput demands without bottlenecks. |

| Custom Configurations | Adapt dimensions, controls, and handling to your facility. |

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | FPH-400W |

| Coil ID | Φ300–Φ1250 mm |

| Coil OD | Φ700–Φ1500 mm |

| Width | 150–400 mm |

| Weight | 10–100 kg |

| Wrap Time | 30–55 sec/package |

| Avg. Speed | 20–30 sec/coil |

| Ring Speed | ≤100 RPM |

| Power | 380 V, 60 Hz, 3-phase; 1.5 kW |

| Materials | Film: OD 100–150 mm, ID 50 mm, W 90–120 mm; Paper/Woven/HDPE: OD 200–450 mm, ID 50 mm, W 90–120 mm |

| Controls | Manual/auto; inverter; reset-to-origin |

| Safety | Guardrails; soft start/stop; special brake |

| Customization | Per client specs |

Ideal Applications & Industries

- Rubber Hose Producers: Safeguard hydraulic and pneuma

The FPH-400 Hose Coil Wrapping Machine offers streamlined packaging for hose coils, improving efficiency and safeguarding products during transportation. With automated wrapping capabilities, it minimizes manual effort and reduces packaging material waste, delivering a cost-effective and reliable solution tailored for high-demand industrial applications.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

PE Corrugated Hose Coil Wrappin

The FPCA-200H coil wrapper offers reliable, automated wrapping for steel and aluminum coils, enhancing both protection an

View DetailsAutomatic Pipe Coiling and Stra

The hose coiling and strapping machine streamlines the process of coiling and packaging hoses with precision and speed. D

View DetailsAutomatic Hose Coil Packing Mac

The automatic hose packing line integrates coiling, strapping, and wrapping into a fully automated process, ensuring spee

View DetailsAutomatic hose wrapper FPCA-300

The automatic hose wrapper streamlines the packaging process by providing fast, consistent wrapping for hoses of various

View DetailsCorrugated hose wrappinging mac

The corrugated hose packing machine streamlines the process of wrapping corrugated hoses, providing durable and secure pa

View DetailsHose Coil wrapping machinery FP

The FPH-500 Hose Coil Wrapping Machine provides streamlined wrapping for hose coils, ensuring consistent protection and s

View DetailsHose wrapping machine FPH-300

The FPH-300 Hose Wrapping Machine offers reliable, high-speed wrapping for hoses of different sizes, ensuring enhanced pr

View DetailsHose Coil packing machinery FPH

The FPH-200 Hose Coil Packing Machinery is a high-performance packaging solution tailored for hose coils. Equipped with a

View DetailsHose film wrapper FPS-300H

A hose film wrapper is an efficient packaging solution designed to wrap hoses tightly with protective film, safeguarding

View DetailsHose Wrap Machine

The hose wrap machine is an advanced packaging tool engineered for wrapping hoses with precision and speed. It provides c

View Details