PE Corrugated Hose Coil Wrapping Machine FPCA-200H

Project Information

Our Automatic Hose Coil Packing Machine expertly wraps hoses and other ring-shaped products with a high-efficiency method that delivers uniform, attractive packaging. By automating the process, it significantly reduces labor and material waste, while providing multi-layer protection against moisture, dust, and corrosion. The result is a neat, durable package that safeguards your products through storage and transport.

Key Benefits

Labor reduction

Material saving

Multi-layer protection

Damage prevention

Professional finish

The FPCA-200 PE Corrugated Hose Coil Wrapping Machine delivers uniform, deformation-free wrapping with minimal manual effort. Its rugged horizontal support and turnkey PLC/HMI controls ensure consistent, professional packages—every time.

The Challenge: Manual Wrapping Risks

- Coil Flattening: Soft hoses distort under poor support, causing uneven tension and rework.

- Variable Wrap Quality: Generic tension control leads to loose ends, inconsistent overlap, and wasted material.

- High Labor Demand: Manual handling and frequent size changes slow throughput and increase training needs.

- Complex Maintenance: Disparate hardware and wiring raise downtime risks and upkeep costs.

- Spec Variety: Different IDs, ODs and widths require flexible support and quick adjustments.

- Lengthy Installation: Separate switchgear, sensors and wiring extend commissioning time.

The Solution: FPCA-200 Key Advantages

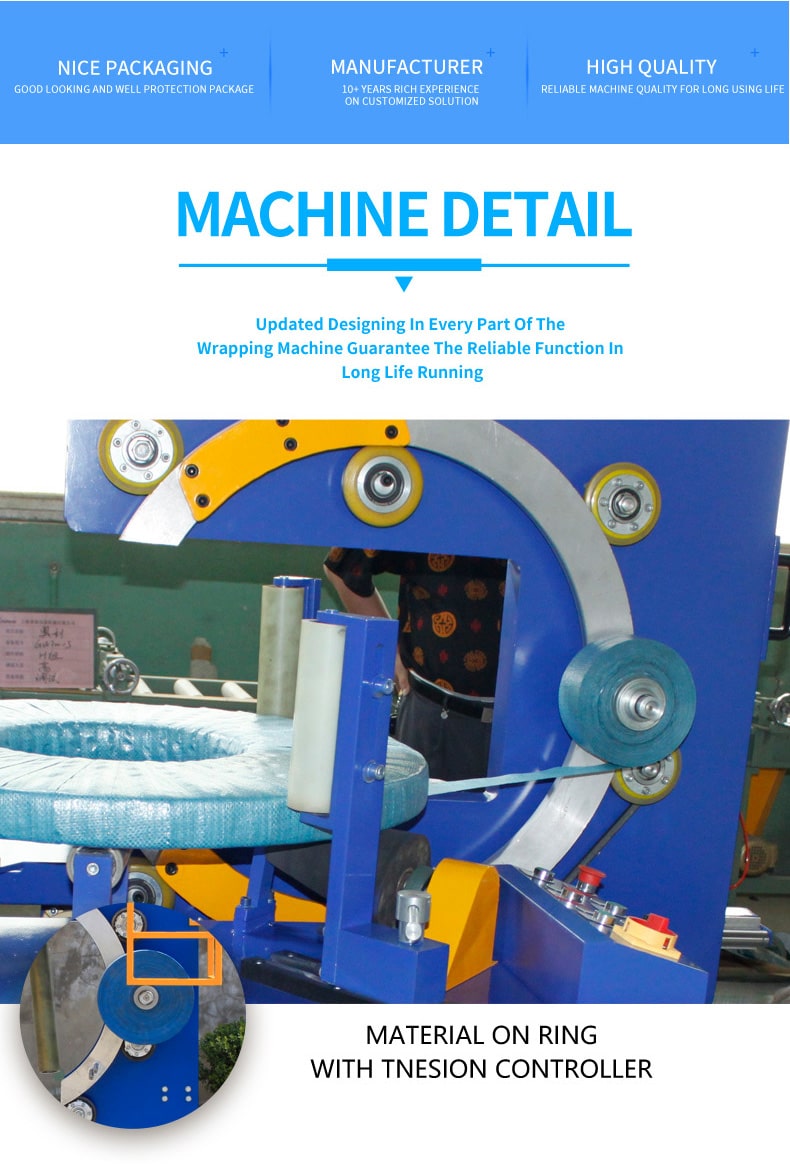

Wuxi BuHui’s FPCA-200 combines robust cradle support, inverter-adjustable tension and speed, plus a pre-housed PLC/HMI panel for a turn-key, semi-automatic wrapping solution.

| Feature | Benefit / ROI |

|---|---|

| Robust Horizontal Cradle | Maintains coil shape for uniform tension and perfect seals. |

| Adjustable Rollers & Cradles | Fits Φ200–350 mm ID, Φ500–650 mm OD, 150–300 mm width—quick setup. |

| Eye-Through Stretch Film | Delivers dust- and moisture-resistant finish; add paper/HDPE layer. |

| Auto Clamper & Cutter | Eliminates loose tails, cuts precisely—cuts waste and cycle time. |

| Pre-housed PLC/HMI Panel | Turnkey wiring and sensors ensure reliable operation, faster startup. |

| Inverter-Controlled Speed & Tension | Fine-tune wrap parameters for consistent overlap and minimal film use. |

| Semi-Auto Size Versions | Optimized for specific coil sizes—reduces training and changeover. |

| ISO9001 & CE Certified | Guaranteed durability, predictable performance, minimal downtime. |

| Ergonomic Single-Operator Flow | One person loads, wraps and unloads—lowers labor needs and improves safety. |

Technical Specifications

| Specification | Details |

|---|---|

| Model | FPCA-200 |

| Coil ID | Φ200–350 mm |

| Coil OD | Φ500–650 mm |

| Width | 150–300 mm |

| Weight | 10–50 kg |

| Wrap Time | 25–35 s/coil |

| Max Speed | 100 r/min (inverter) |

| Power | 380 V, 60 Hz, 3 ph; ~2 kW |

| Film | Stretch film 90 mm w; optional paper/HDPE layer |

| Overlap | 10–90 % |

| Control | PLC & HMI with pre-wired switchgear |

| Safety | Emergency stop, alarms, guardrails |

| Certifications | ISO9001, CE |

Ideal For

- PE Hose Makers: Immediate, deformation-free wrapping post-extrusion.

- Pipe Extruders: Semi-auto wrapping for soft, small-to-medium coils.

- Industrial Hose Plants: Consistent quality with minimal manual work.

- Line Integrators: Inline install with turnkey controls for fast commissioning.

- High-Mix Operations: Rapid changeover via stored semi-auto presets.

- Low-Upkeep Facilities: Proven design maximizes uptime, minimizes service.

Request a Quote

Ready to eliminate deformation and boost packaging consistency? Contact Wuxi BuHui today to customize FPCA-200 for your production needs and streamline your hose coil packaging.

The FPCA-200H coil wrapper offers reliable, automated wrapping for steel and aluminum coils, enhancing both protection and presentation. Designed for durability and ease of use, it ensures consistent wrapping quality, reducing manual handling and boosting operational efficiency. Ideal for industrial settings requiring robust and efficient coil packaging solutions.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

Automatic Pipe Coiling and Stra

The hose coiling and strapping machine streamlines the process of coiling and packaging hoses with precision and speed. D

View DetailsAutomatic Hose Coil Packing Mac

The automatic hose packing line integrates coiling, strapping, and wrapping into a fully automated process, ensuring spee

View DetailsAutomatic hose wrapper FPCA-300

The automatic hose wrapper streamlines the packaging process by providing fast, consistent wrapping for hoses of various

View DetailsHose Coil wrapping machinery FP

The FPH-500 Hose Coil Wrapping Machine provides streamlined wrapping for hose coils, ensuring consistent protection and s

View DetailsHose Coil wrapping machinery FP

The FPH-400 Hose Coil Wrapping Machine offers streamlined packaging for hose coils, improving efficiency and safeguarding

View DetailsHose Coil packing machinery FPH

The FPH-200 Hose Coil Packing Machinery is a high-performance packaging solution tailored for hose coils. Equipped with a

View DetailsHose film wrapper FPS-300H

A hose film wrapper is an efficient packaging solution designed to wrap hoses tightly with protective film, safeguarding

View Details