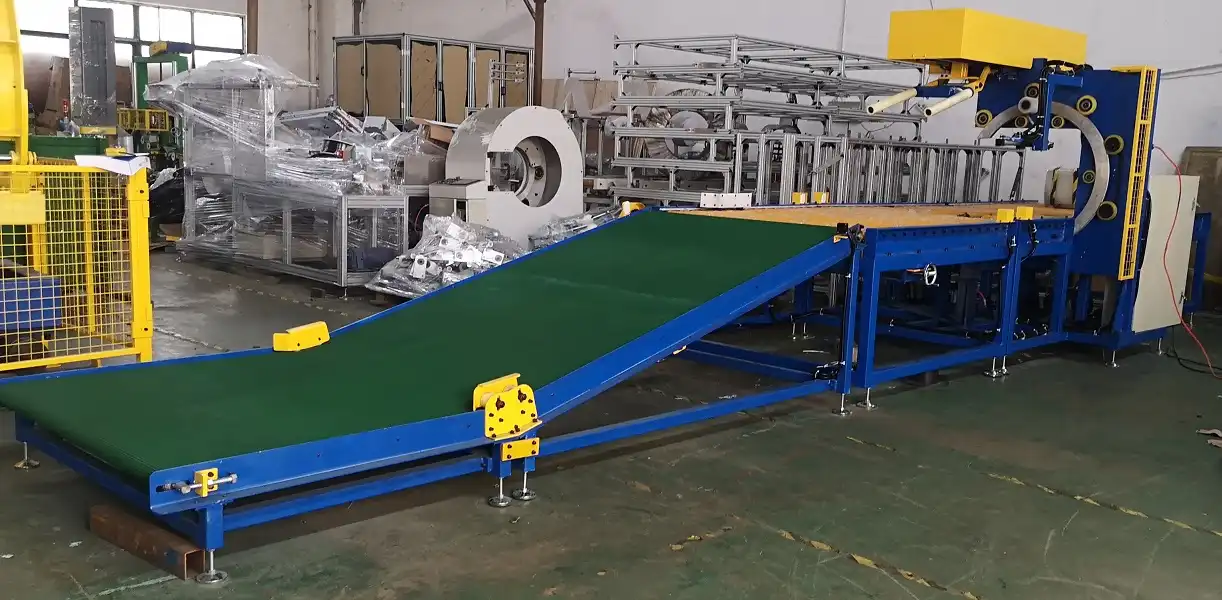

Automatic Hose Coil Packing Machine

Project Information

All equipment can be customized to meet your specific packaging requirements, ensuring efficiency, precision, and reliability in every operation.

Key Features:

Custom: Matches your line

Quality Parts: Brand-backed

PLC: Precise control

VFD: Overlap adjustable

Variable Speed: Adaptable

Reset: Consistent precision

Transform your hose and pipe coil packaging with Wuxi BuHui’s Automatic Hose Coil Packing Machine. This PLC/HMI-driven horizontal line unites conveying, centering, wrapping, cutting and stacking into a single, high-throughput solution. With inverter-adjustable speeds, tension and overlap control, you get uniform, damage-free wrapping—operated by one person for maximum efficiency and safety.

Challenges of Manual Hose Coil Packing

- High Labor Demand: Multiple operators needed for loading, wrapping and unloading heavy coils.

- Inconsistent Coverage: Manual tension and overlap adjustments lead to uneven wraps and rework.

- Safety Risks: Manual handling strains operators and increases injury potential.

- Lengthy Changeovers: Varying coil sizes require frequent, time-consuming resets.

- Throughput Bottlenecks: Separate steps and lack of automation slow overall packing speed.

Features & Benefits

The PLC/HMI-controlled line integrates every step under a single-operator interface, ensuring fast, reliable and safe packaging.

| Feature | Benefit / ROI |

|---|---|

| PLC/HMI with Stored Recipes | Recall settings for different coil sizes in seconds—cuts setup time and errors. |

| Integrated Conveyors | Automates coil infeed/outfeed, freeing one operator for supervision only. |

| Centering Rollers | Aligns coil perfectly for even wrapping, regardless of diameter or width. |

| Adjustable Speeds (Ring & Rollers) | Fine-tune wrap and transport speeds to suit any material or size. |

| Tension & Overlap Control (10–90%) | Guarantees snug, waste-optimized wraps that protect against dust and damage. |

| Auto Film Feeder & Cutter | Feeds and cuts stretch film or paper automatically—eliminates manual steps. |

| Supportive Lifting Rollers | Raises coil smoothly into the wrapping zone—reduces operator strain. |

| Real-Time Alarms & Monitoring | Instant fault alerts minimize downtime and maintain wrap quality. |

| Soft Start/Stop & Auto-Reset | Protects equipment and operator—ensures precise positioning each cycle. |

| Ergonomic Table Height | Adjustable 880–890 mm height and guardrails enhance operator comfort. |

| Front/Back Positioning | Automatically aligns coil pre- and post-wrap for flawless placement. |

| Stacking Conveyor | Transfers finished coils to stack area—streamlines post-wrap handling. |

| Wide Material Compatibility | Handles stretch film, paper, HDPE or woven materials for any protection level. |

Technical Specifications

| Specification | Details |

|---|---|

| Model | Automatic Hose Coil Packing Line |

| Coil ID | Φ300–Φ1200 mm |

| Coil OD | Φ700–Φ1400 mm |

| Width | 120–300 mm |

| Weight | 10–150 kg |

| Wrap Time | 28–45 sec per coil |

| Max Ring Speed | 100 r/min (VFD-controlled) |

| Power | 380 V, 60 Hz, 3-phase (~3.8 kW) |

| Materials | Stretch film (ID 50 mm, OD 100–150 mm, width ~90 mm); paper/HDPE/woven optional |

| Overlap | 10%–90% |

| Controls | PLC & HMI touchscreen; multiple profiles stored |

| Conveyor Length | Customizable |

| Centering Device | Adjustable cylinder-driven rollers |

| Support Rollers | PU-covered lifting rollers |

| Table Height | 880–890 mm; max width 1600 mm |

| Safety | Guardrails, alarms, soft start/stop, auto-reset |

| Environment | Standard plant conditions (consult for extremes) |

| Customization | Special conveyor layouts and handling options |

The automatic hose packing line integrates coiling, strapping, and wrapping into a fully automated process, ensuring speed and precision. Perfect for high-volume production, it reduces labor dependency, enhances packaging consistency, and boosts operational efficiency. This innovative system delivers neatly packed hoses, ready for storage or transport, with minimal effort.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

PE Corrugated Hose Coil Wrappin

The FPCA-200H coil wrapper offers reliable, automated wrapping for steel and aluminum coils, enhancing both protection an

View DetailsAutomatic Pipe Coiling and Stra

The hose coiling and strapping machine streamlines the process of coiling and packaging hoses with precision and speed. D

View DetailsAutomatic hose wrapper FPCA-300

The automatic hose wrapper streamlines the packaging process by providing fast, consistent wrapping for hoses of various

View DetailsCorrugated hose wrappinging mac

The corrugated hose packing machine streamlines the process of wrapping corrugated hoses, providing durable and secure pa

View DetailsHose Coil wrapping machinery FP

The FPH-500 Hose Coil Wrapping Machine provides streamlined wrapping for hose coils, ensuring consistent protection and s

View DetailsHose Coil wrapping machinery FP

The FPH-400 Hose Coil Wrapping Machine offers streamlined packaging for hose coils, improving efficiency and safeguarding

View DetailsHose wrapping machine FPH-300

The FPH-300 Hose Wrapping Machine offers reliable, high-speed wrapping for hoses of different sizes, ensuring enhanced pr

View DetailsHose Coil packing machinery FPH

The FPH-200 Hose Coil Packing Machinery is a high-performance packaging solution tailored for hose coils. Equipped with a

View DetailsHose film wrapper FPS-300H

A hose film wrapper is an efficient packaging solution designed to wrap hoses tightly with protective film, safeguarding

View DetailsHose Wrap Machine

The hose wrap machine is an advanced packaging tool engineered for wrapping hoses with precision and speed. It provides c

View Details