HDPE pipe packing machine

Project Information

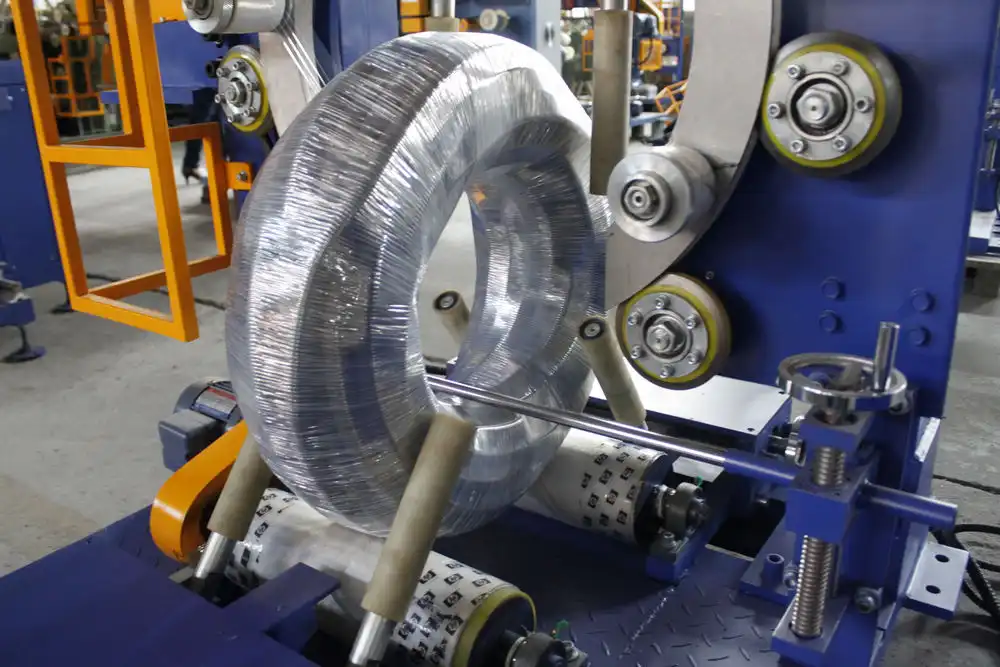

The vertical winding packaging machine is an advanced solution specifically designed for packaging HDPE hose coils, addressing the challenges associated with both light and heavy coiled materials. Its user-friendly vertical design with the opening facing upward simplifies feeding and discharge processes, making it ideal for efficient and reliable operation.

Key Features

Vertical Design:

The upward-facing opening streamlines material feeding and discharge, enhancing operational convenience.

Material Versatility:

Capable of handling both light and heavy HDPE hose coils with precision.

Durable Packaging:

Ensures hose coils are securely wrapped, preventing damage during storage and transportation.

Automate consistent, protective wrapping of pipes and cylindrical products with Wuxi BuHui’s Pipe Wrapping Station. Inverter-controlled speed and adjustable tension handle 5–100 kg workpieces (OD 600–1400 mm, ID 300–1200 mm, width 100–350 mm) in end-of-line wrapping.

The Challenge: Overcoming Pipe Wrapping Issues

- Size & Changeovers: OD 600–1400 mm, ID 300–1200 mm, width 100–350 mm require frequent manual setups and downtime.

- Uneven Seals: Manual tension and speed lead to gaps, moisture ingress, and surface damage.

- Low Throughput: Semi-automatic methods struggle to hit 12–30 sec/pcs targets, wasting labor hours.

- Material Waste: Inaccurate overlap or tension boosts film and belt costs.

- Safety & Equipment Life: Abrupt starts/stops stress components; lack of soft start affects product integrity.

- Integration & Maintenance: Stations must fit existing lines, offer clear fault alerts, and allow quick servicing.

- Media Flexibility: Must support LLDPE, PVC, knit belt, compound paper without complex retooling.

The Solution: Features & Benefits of the Pipe Wrapping Station

| Feature | Benefit & ROI |

|---|---|

| Inverter-Controlled Speed & Tension | Fine-tune wrap speed (20–120 RPM) and tension for tight, uniform seals—cuts rework and waste. |

| Soft Start/Stop & Jog Functions | Smooth acceleration protects machine and product—extends equipment life. |

| Sensor/Manual Reset Positioning | Rapid, repeatable changeovers—minimizes downtime between sizes. |

| Adjustable Protective Rollers | Securely guide varied diameters—prevents shifting and surface marks. |

| Reinforced Rotating Ring & PU Wheels | Durable core and precise grip maintain consistent wrap tension under load. |

| Overlap Control (10%–90%) | Balance protection and film use—reduces material cost. |

| Media Support & Optional HMI/Frame | Handle LLDPE, PVC, knit belt, compound paper; clean auto cut-off and touchscreen ease operation. |

| Branded Components | Siemens PLC/HMI, Schneider inverters, Autonics sensors ensure reliable uptime. |

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | Wuxi BuHui Pipe Wrapping Station |

| Workpiece Weight | 5–100 kg |

| Width Range | 100–350 mm |

| OD Range | 600–1400 mm |

| ID Range | 300–1200 mm |

| Wrap Cycle | 12–30 sec/pcs |

| Ring Speed | 20–120 RPM (inverter) |

| Power | Approx. 2.0 kW, 380 V/50 Hz |

| Control | PLC/HMI, sensor/manual reset, jog, soft start/stop |

| Materials | LLDPE, PVC, knit belt, compound paper |

| Safety | Guardrails, emergency stop, overload protection |

| Customization | Adjustable speeds, tension, roller spacing, media frame |

Ideal Applications & Industries

- Pipe & Tube Manufacturers: Automated, protective wrapping to prevent corrosion and damage.

- Tire & Cylindrical Component Packaging: Secure wrapping for varied diameters and materials.

- Hose & Cable Producers: Consistent seals on reels and coils.

- Contract Packaging: Flexible station for multiple media and sizes.

- Logistics & Warehousing: End-of-line integration for stable, damage-free loads.

- OEMs & System Integrators: Plug-and-play into automated lines.

Why Wuxi BuHui?

Wuxi BuHui’s Pipe Wrapping Station combines inverter precision, sensor reliability, and branded components for fast (12–30 sec), uniform wrapping. It reduces waste, cuts labor, and protects products—delivering safe, high-throughput end-of-line performance.

Request a Quote

Contact Wuxi BuHui with your pipe specifications and layout needs. We’ll configure a customized Pipe Wrapping Station that maximizes efficiency, minimizes waste, and ensures consistent protection.

The vertical winding packaging machine specially designed for fhose of hdpe coiled materials is introduced, which can be applied to light and heavy coiled materials. The design with the opening facing up is convenient for feeding and discharging, and convenient for operation.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

Plastic pipe packing

Plastic pipe packing ensures secure and efficient transportation by protecting pipes from damage during handling and ship

View Details