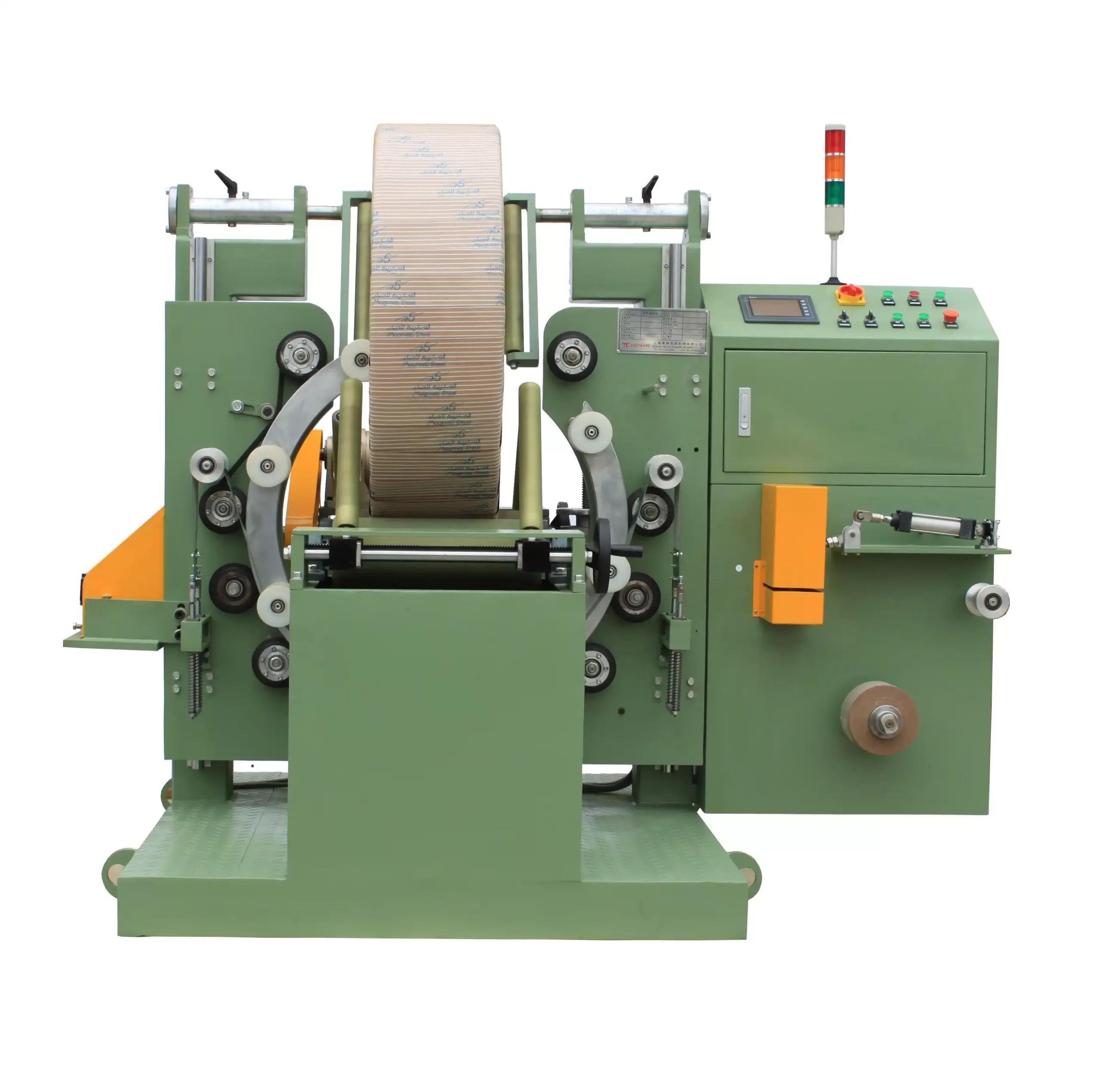

Tyre Packing Machine FPT-300

Project Information

The automatic packaging machine is a specialized solution for packing large tires and rolls, tailored to meet the demands of industries like manufacturing, distribution, and logistics. Its advanced features and high-speed operation make it a valuable tool for streamlining the packing process.

Key Features:

Fully automatic operation boosts efficiency and consistency

Handles large tyres and rolls with ease

Auto material fixing and cutting for precision

Calculates material length to optimize usage and cut waste

Manual wrapping of large truck tyres is slow, inconsistent, and risky—workers strain to secure heavy tyres, materials get wasted, and safety hazards arise. The FPT-300 Truck Tyre Wrapping Machine from Wuxi BuHui automates the process, delivering uniform, high-quality wraps in just 35–50 seconds per tyre. Simply power on, connect the air supply, and start efficient, reliable packaging for tyre IDs 750–1,200 mm, ODs 1,000–1,400 mm, and widths 80–400 mm.

Key Challenges

- High Labor, Low Output: Multiple operators and slow manual cycles limit throughput.

- Tyre Movement Risks: Unstable tyres wobble during wrapping, causing uneven tension and potential injuries.

- Frequent Adjustments: Switching tyre sizes requires time-consuming mechanical setup.

- Inconsistent Quality: Manual tension control yields uneven coverage and subpar protection.

- Material Waste: Hand-measuring and cutting films or belts leads to excess scrap.

- Deployment Delays: Complex installs and poor fault feedback extend downtime.

- Ergonomic Concerns: Handling bulky tyres without proper guarding strains operators.

Features & Benefits

| Feature | Benefit / ROI |

|---|---|

| Fixed feed & auto length calculation | Eliminates waste and cuts setup time by measuring and cutting wrap material automatically. |

| PLC-controlled ring height | Adapts instantly to tyre IDs 750–1,200 mm; slashes adjustment effort and downtime. |

| Inverter-driven soft start/stop | Smooth ring and roller movement protects tyres and equipment; enhances operator safety. |

| 35–50 sec per tyre | Delivers rapid, consistent wraps—boosts daily output and lowers labor cost per unit. |

| Multi-material compatibility | Supports stretch film, PE/LDPE, knit belt, PP, silver paper, and more to meet all packaging needs. |

| Adjustable overlap (10%–90%) | Tailors coverage and tightness for optimal protection and branding. |

| Guardrails & robust support | Prevents tyre wobble; ensures stable wrapping and safeguards operators. |

| Sensor feedback & auto reset | Maintains consistent cycle start/stop; real-time error display speeds troubleshooting. |

| Plug-and-play design | Ships ready to run—just power on and connect air to start packaging immediately. |

| Precise tension control | Customizes wrap tightness per tyre and material, ensuring reliable protection. |

| Indicator alarms | Alerts operators instantly; minimizes downtime by pinpointing faults. |

| Durable friction wheels | Engineered for long-term use with minimal maintenance. |

| Non-skilled operator friendly | Intuitive HMI and automated functions enable easy operation after brief training. |

Technical Specifications

| Specification | Details |

|---|---|

| Model | FPT-300 |

| Voltage | AC 380 V, 50 Hz (customizable) |

| Power | 2.5 kW |

| Tyre ID | 750–1,200 mm |

| Tyre OD | 1,000–1,400 mm |

| Tyre Width | 80–400 mm |

| Weight Capacity | 20–120 kg |

| Wrapping Speed | 35–50 sec/tyre |

| Ring Speed | 30–80 rpm (inverter-controlled) |

| Overlap Rate | 10%–90% |

| Materials | Stretch film, PE, LDPE, paper, knit belt, PP, silver paper |

| Control System | PLC with touchscreen HMI; sensor-based ring reset |

| Safety Features | Guardrails, protective covers, emergency stop |

| Deployment | Compact, plug-and-play—power on & connect air |

| Customization | Optional branding tape applicator, special dimensions |

Ideal Applications

- Tyre Manufacturers: Scale high-speed wrapping with consistent quality.

- Distribution Centers: Streamline packaging for storage and shipment.

- Fleet Services: Protect spare tyres with professional wraps.

- OEM Lines: Integrate into final assembly for reliable packaging.

- Safety-Focused Facilities: Leverage built-in guards and sensors to reduce injuries.

Request a Quote

Ready to transform your truck tyre packaging? Contact Wuxi BuHui today for a tailored quotation and discover how the FPT-300 can elevate your efficiency, quality, and safety.

The FPT-300 Tyre Packing Machine is designed for efficient, high-speed wrapping of tires, enhancing packaging protection and reducing labor costs. Its robust construction and adjustable settings accommodate various tire sizes, making it versatile for different production needs. This machine ensures reliable, consistent packaging, ideal for streamlining tire handling operations.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

Tyre Packing Machine FPT-100

The FPT-100 Tyre Packing Machine provides efficient, reliable tire packaging for safe transport and storage. With a compa

View DetailsTyre Packing Machine FPT-200

The Tyre Packing Machine FPT-200 is a high-efficiency solution designed to streamline tire packaging processes. It offers

View DetailsTyre packing machine

A tyre packing machine is an innovative solution for wrapping and securing tyres efficiently. It provides protective pack

View DetailsHorizontal Tyre Stretch Wrapper

A tyre wrapper is an advanced packaging machine designed to wrap tyres with stretch film or other protective materials ef

View Details