Copper Coil Packaging line

Project Information

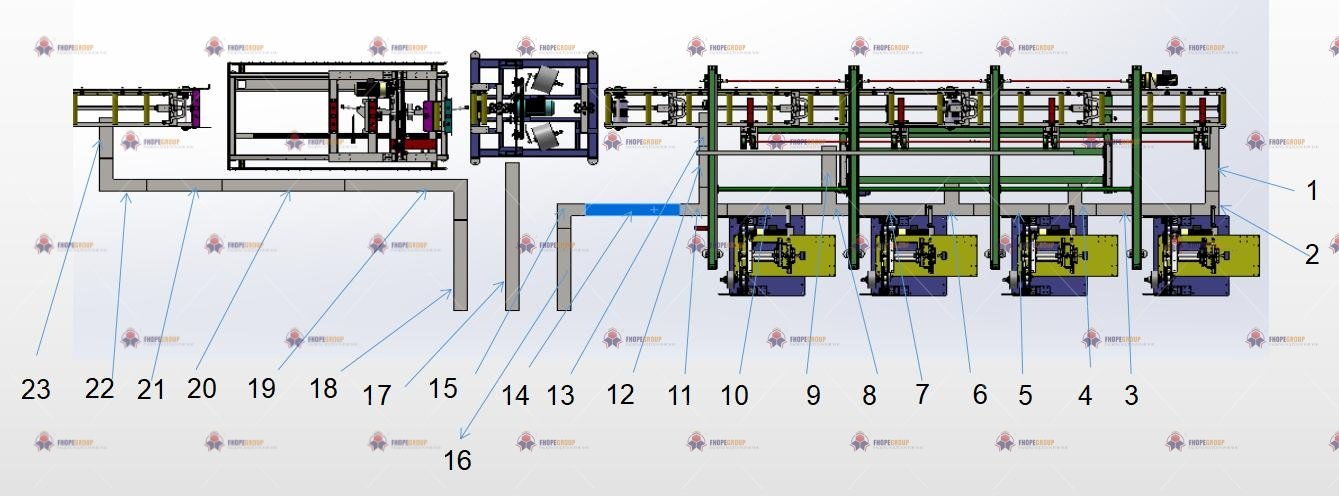

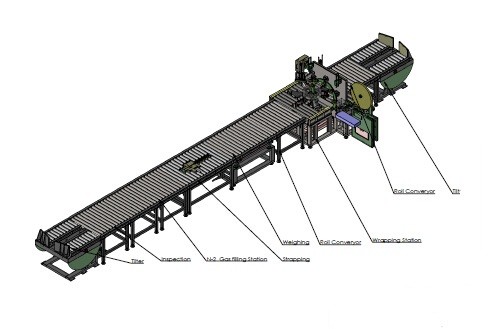

The automatic copper coil packaging line includes a turnover machine, auto conveyors, and a wrapping machine. It can be integrated with a stacker and pallet packaging machine for a fully automated process from production to warehouse, requiring no manual operation. This high-speed, efficient system is widely used in the packaging industry.

Key Features:

Main Equipment: Turnover machine, conveyors, wrapping machine.

Packaging Materials: PE stretch film, paper, PP woven sheet.

Full Automation: Complete process from production to warehouse.

Flexible Directions: Supports vertical and horizontal packaging.

Maintenance Services: Regular maintenance options tailored to customer needs.

Wuxi BuHui’s Automatic Copper Strip Coil Packaging Line unifies coil transfer, tension-controlled strapping, wrap/film covering, imaging, labeling, and automated stacking under PLC/HMI control—delivering uniform, damage-free packaging at high throughput.

The Challenge

- Disconnected workflow: Separate modules cause delays, manual handling, and misalignment.

- Frequent changeovers: Varying OD (600–1000 mm), ID (344–400 mm), width (20–200 mm) and weight (≤ 500 kg) demand constant setup.

- Variable quality: Inconsistent strap tension or wrap overlap risks coil damage.

- Bottlenecks: Packaging must keep pace with 20–30 coils/hour production rates.

- Traceability gaps: Lack of seamless imaging/MES integration hinders QA and records.

- Safety risks: Manual transfer, strapping, stacking endangers operators.

- Maintenance delays: No real-time fault detection prolongs downtime.

Solution: Features & Benefits

| Feature / Component | Benefit / ROI |

|---|---|

| Coil Transfer & Orientation | Auto interface with slitting lines; vertical-to-horizontal orientation cuts manual handling. |

| PLC/HMI Central Control | Recipe storage for all specs; real-time monitoring and alarms ensure consistency. |

| Intelligent Strapping | PLC-tensioned PET/PE/steel straps prevent loose or over-tight belts, reducing waste. |

| Wrap & Film Covering | Adjustable tension/overlap provides moisture and dust protection with repeatable quality. |

| End-Face Imaging & MES | Inline scanning uploads QA data to MES for full traceability. |

| Automated Labeling | Inline barcode/label application streamlines downstream handling. |

| Automated Stacking | Stacks coils onto pallets automatically—eliminates manual labor. |

| Quick Changeover | Fixture adjustments and PLC recipes switch formats in minutes. |

| Fault Detection & Alarms | Immediate alerts on misfeeds or strap failures minimize downtime. |

| Safety & Ergonomics | Guarding, interlocks, light curtains, and E-stops protect operators. |

Technical Specs

| Parameter | Specification |

|---|---|

| Coil OD | 600–1000 mm |

| Coil ID | 344–400 mm |

| Width | 20–200 mm |

| Weight Capacity | Up to 500 kg |

| Strapping | PET/PE/steel; PLC-controlled tension |

| Wrapping | LLDPE film or paper; adjustable overlap |

| Imaging | Inline end-face camera; MES integration |

| Control | PLC/HMI with recipe library and data logging |

| Conveyors | Inverter-driven, synchronized speeds |

| Stacking | Automated palletizer |

| Power | 380 V 3 phase, 50 Hz |

| Air | 0.6–0.8 MPa clean, dry |

Why Wuxi BuHui?

- Turnkey automation: From transfer to stacking in one PLC-controlled line.

- Consistent protection: Precise tension and wrap ensure damage-free coils.

- High throughput: Matches 20–30 coils/hour production speeds.

- Traceability: Imaging and labeling integrate with MES records.

- Safety first: Automated handling and advanced safeguards reduce risk.

Request a Quote

Ready to optimize your copper coil packaging? Contact Wuxi BuHui with your specs for a tailored solution and competitive quote.

A copper coil packaging line automates the entire process from production to storage, featuring equipment like turnover machines, conveyors, and wrapping machines. Using materials such as PE stretch film and PP woven sheets, it ensures high-speed, efficient packaging with vertical or horizontal options and requires no manual operation.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635