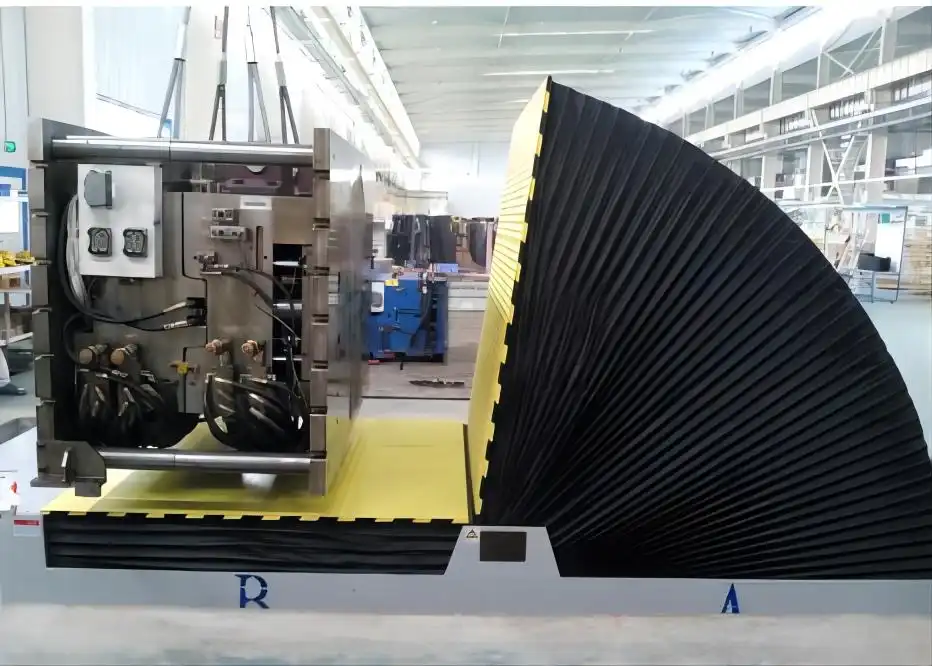

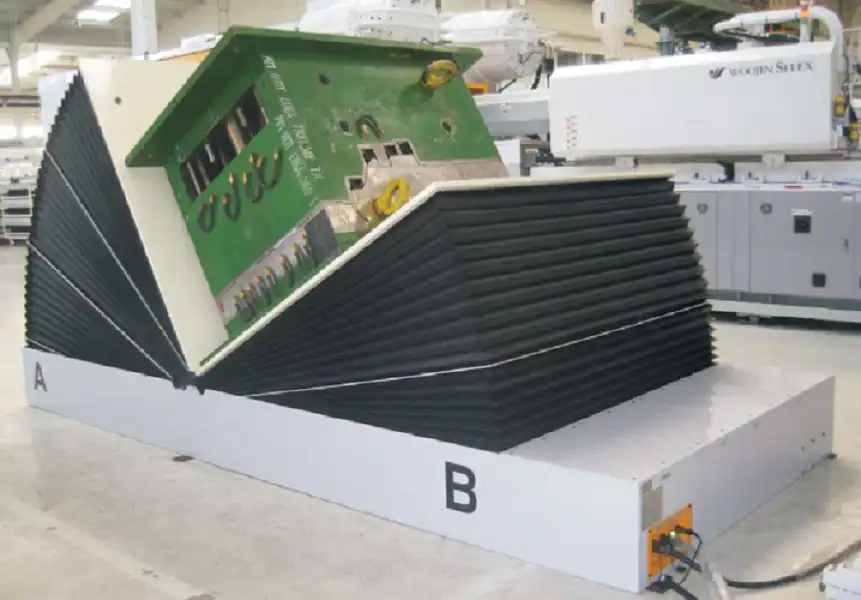

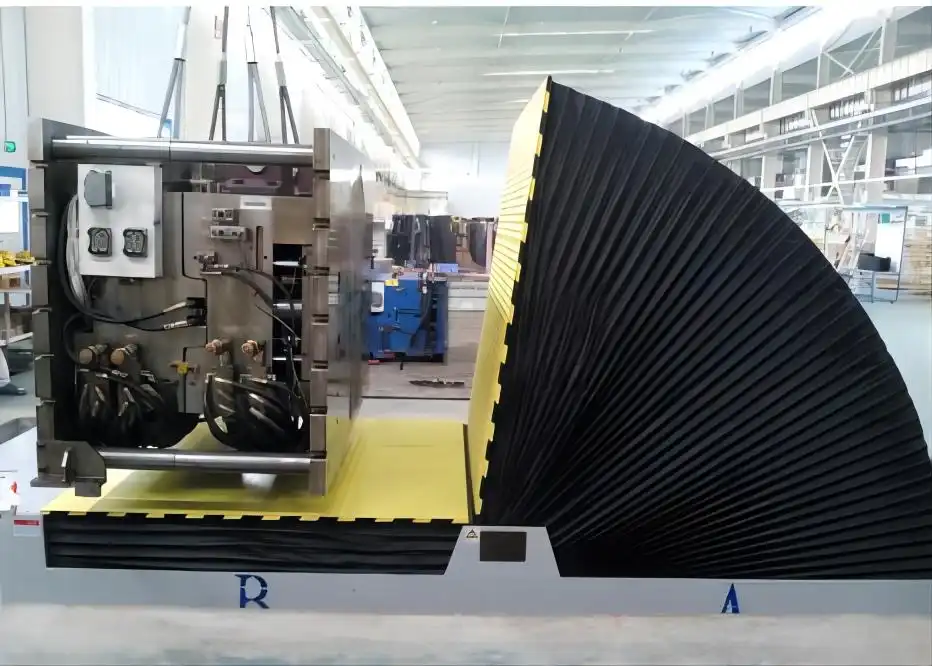

Mold flipper

Project Information

Flipper lift tables are versatile machines designed for various industrial applications, including mold processing, die handling, engine assembly, and material inversion. They provide safe and efficient solutions for flipping molds and dies by 90 to 180 degrees without causing damage.

Key Features

Applications: Mold/die flipping, engine assembly, roll inversion

Capacity: 1–60 t hydraulic handling

Customizable: Deck size & tilt speed

Crane-Free: Certified for safer, faster workflows

Handling heavy injection molds with cranes or hoists is risky, slow, and can damage tooling. The Injection Mold Flipper Table uses hydraulics and inverter-driven soft start/stop to rotate molds 180° safely and smoothly—keeping operators clear, cutting downtime, and boosting throughput by up to 40%.

The Challenge

- Safety Risks: Manual or crane flips expose operators to falling loads and pinch points.

- Poor Accuracy: Inconsistent stops cause misalignment, rework, and premature tool wear.

- Equipment Strain: Sudden starts/stops stress hydraulics and molds, shortening service life.

- Large Footprint: Traditional setups occupy valuable floor space and limit cell layout.

Features & Benefits

| Feature | Customer Benefit |

|---|---|

| 180° Hydraulic Flipper | Full inversion for easy access—streamlines maintenance and operation. |

| Inverter Soft Start/Stop | Smooth motion reduces shock, extends hydraulic life, and protects molds. |

| Dual Safety Limits | Mechanical stoppers + electronic sensors lock at any angle—100% safe operation. |

| Electric Control Panel | HMI with remote option enables one-button flips—keeps operators out of harm’s way. |

| Compact Frame | Fits tight cells; optional pit mounting for flush installation. |

| CE Safety Guards | Meets global standards with emergency stop and interlocks for peace of mind. |

Technical Specifications

| Parameter | Specification |

|---|---|

| Rotation Capacity | 0–180° (dual 90° segments) |

| Max Load | Up to 40 t (customizable) |

| Drive Method | Hydraulic cylinders with inverter-controlled pump |

| Control | Electric panel + remote-control option |

| Table Size | Custom to mold (e.g., 2500×2500 mm) |

| Power | AC 380 V/50 Hz/3-Phase (other voltages optional) |

| Certifications | CE, ISO |

Ideal Applications

- Injection Molding Plants: Faster changeovers, safer maintenance.

- Die & Mold Shops: Precise flipping for inspection and repair.

- Thermoplastic Processing: Handle heavy tooling in tight cells.

- Automotive Manufacturing: Reliable inversion for high-volume runs.

- Aerospace & Defense: Safely rotate large, delicate molds.

Why Wuxi BuHui?

- Proven Safety: Exceeds global standards with dual limits and interlocks.

- Tailored Engineering: Custom sizes and capacities to fit any mold.

- Seamless Integration: Compact design and pit-mount option minimize downtime.

- Long-Term Reliability: Soft-start hydraulics and rugged construction reduce upkeep.

- Dedicated Support: From CAD layouts to on-site commissioning and training.

Request a Quote

Ready to transform your mold handling? Contact Wuxi BuHui today with your mold dimensions and load requirements for a custom Injection Mold Flipper Table solution—complete with detailed drawings and competitive pricing.

The Flipper Lift Table is a machine designed for flipping molding boxes (for mating response to drag or for sand shake off) with a safe and efficient operation. It can handle any size portion from 100 LBS to over 100 tons, simply by pressing a button. This makes it very versatile and useful in many industrial applications.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

Mold Flipper Table

The Inject Mold flipper table is a specialized equipment designed for 180 degree turning and flipping of molds, dies, and

View Details