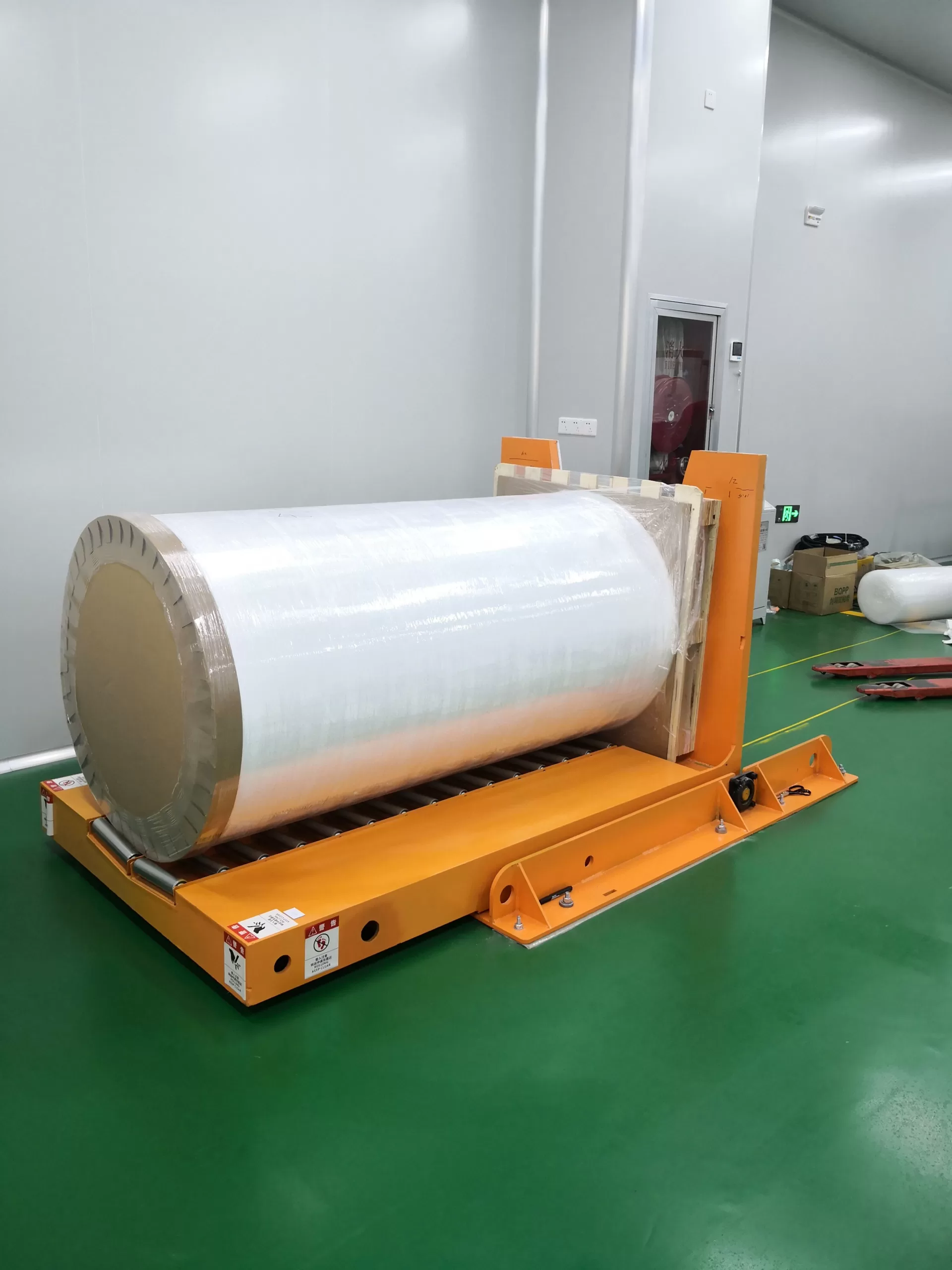

Roll upender

Project Information

The Model FZ-H02 Roll Upender is designed for efficient handling of plastic film rolls, offering precise 90° tilting with a robust and durable build. It ensures smooth operation, minimal maintenance, and adaptability to harsh environments.

Key Features

Capacity: Handles loads up to 2000kg with dimensions of 2400mm length and 1000mm OD.

Hydraulic System: Ensures efficient and smooth turning with adjustable speeds.

Advanced Controls: Equipped with an independent control panel and automatic settings.

Handling heavy paper rolls manually or with basic equipment risks damage, downtime, and operator injury. The Paper Roll Upender tilts up to 2 000 kg loads 90° in just 10 seconds—hydraulic-driven, vibration-free, and built for demanding industrial lines.

Challenge

- Operator Safety: Manual flips or forklift lifts expose workers to heavy loads.

- Material Damage: Abrupt motion and vibration deform cores and cause tears.

- Inconsistent Throughput: Variable cycle times disrupt production flow.

- High Maintenance: Basic equipment lacks safety locks and smooth operation.

Solution & Benefits

| Feature | Benefit |

|---|---|

| 2 000 kg Capacity, C-Frame Design | Safely handles larger paper, carpet, or textile rolls—expanding your load range. |

| Hydraulic Drive with Soft Start/Stop | Achieves smooth 90° tilt in 10 s—minimizing vibration and material stress. |

| Inverter Speed Control | Fine-tunes cycle time to your line’s pace—ensuring consistent throughput. |

| Independent Control Panel | Keeps operators at a safe distance with clear controls and emergency stop. |

| Mechanical & Electronic Locks | Secures position at any angle or on power loss—preventing unintended movement. |

| Vibration-Free Motion | Protects roll integrity—reducing waste and scrap rates. |

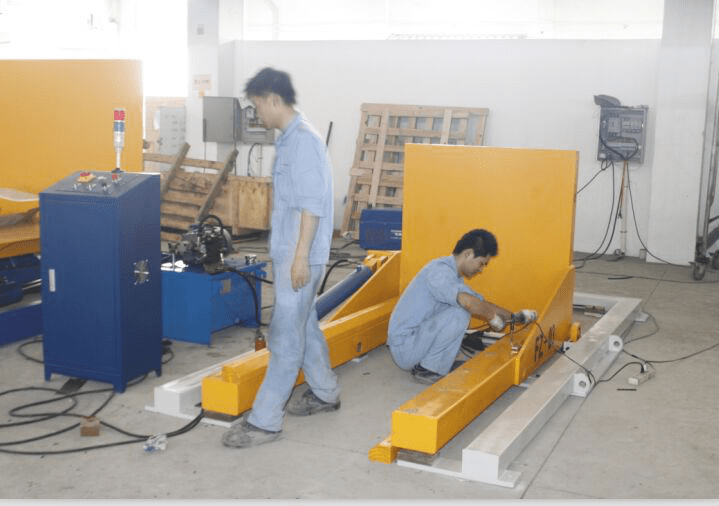

| Robust Steel Structure | Delivers low maintenance and maximum uptime—cutting lifecycle costs. |

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | Paper Roll Upender |

| Load Capacity | Up to 2 000 kg |

| Tilt Angle | 90° |

| Cycle Time | ~10 s per tilt |

| Power Supply | 220 V, 60 Hz, 3 Phase |

| Hydraulic Drive | 2.0 kW heavy-duty station |

| Control | Panel or remote; inverter speed control |

| Table Size | Custom, up to Ø 1 000 mm rolls |

| Safety | Emergency stop; mechanical & electronic restrictors |

| Noise | < 78 dB |

| Environment | –50 °C to +40 °C; ≤ 3 mg/m³ dust |

| Maintenance | Low; modular spare kit included |

Ideal Applications

- Paper & Packaging Plants: Fast reel rotation and safe unloading.

- Textile & Carpet Manufacturers: Gentle handling of heavy fabric rolls.

- Furniture & Automotive Suppliers: Efficient tilting of upholstery rolls.

- Printing & Converting: Streamlined roll changes for high-speed lines.

- Logistics & Warehousing: Secure roll manipulation before storage or shipping.

Company Advantage

- High Throughput: 10 s tilt cycles at 2 000 kg capacity ensure nonstop operations.

- Ultimate Safety: Position locks, restrictors, and remote control protect your team.

- Material Preservation: Vibration-free drive minimizes waste and maintains roll integrity.

- Custom & Low-Maintenance: Modular design adapts to your specs with minimal downtime.

- Energy Efficient: Optimized hydraulic and inverter systems lower power consumption.

Contact Us

Ready to boost safety, speed, and reliability in your roll-handling process? Contact us today for a customized quote on your Paper Roll Upender solution!

Roll upender is a machine used for handling large rolls of paper, curtain, and carpet, it has a heavy-duty and durable structure and is designed for safe operation. The manufacturer, Fhope, aims to provide a safe operating environment for the operator.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

Paper Roll Upender

The Hydrauliccoil upender machine is a custom-designed flat tilter that can handle a load of up to 40Tmold. The upending

View DetailsHydraulic upender

A floor base hydraulic upender/tilter is a machine that is used to rotate heavy objects during operations. It has a stabl

View Details