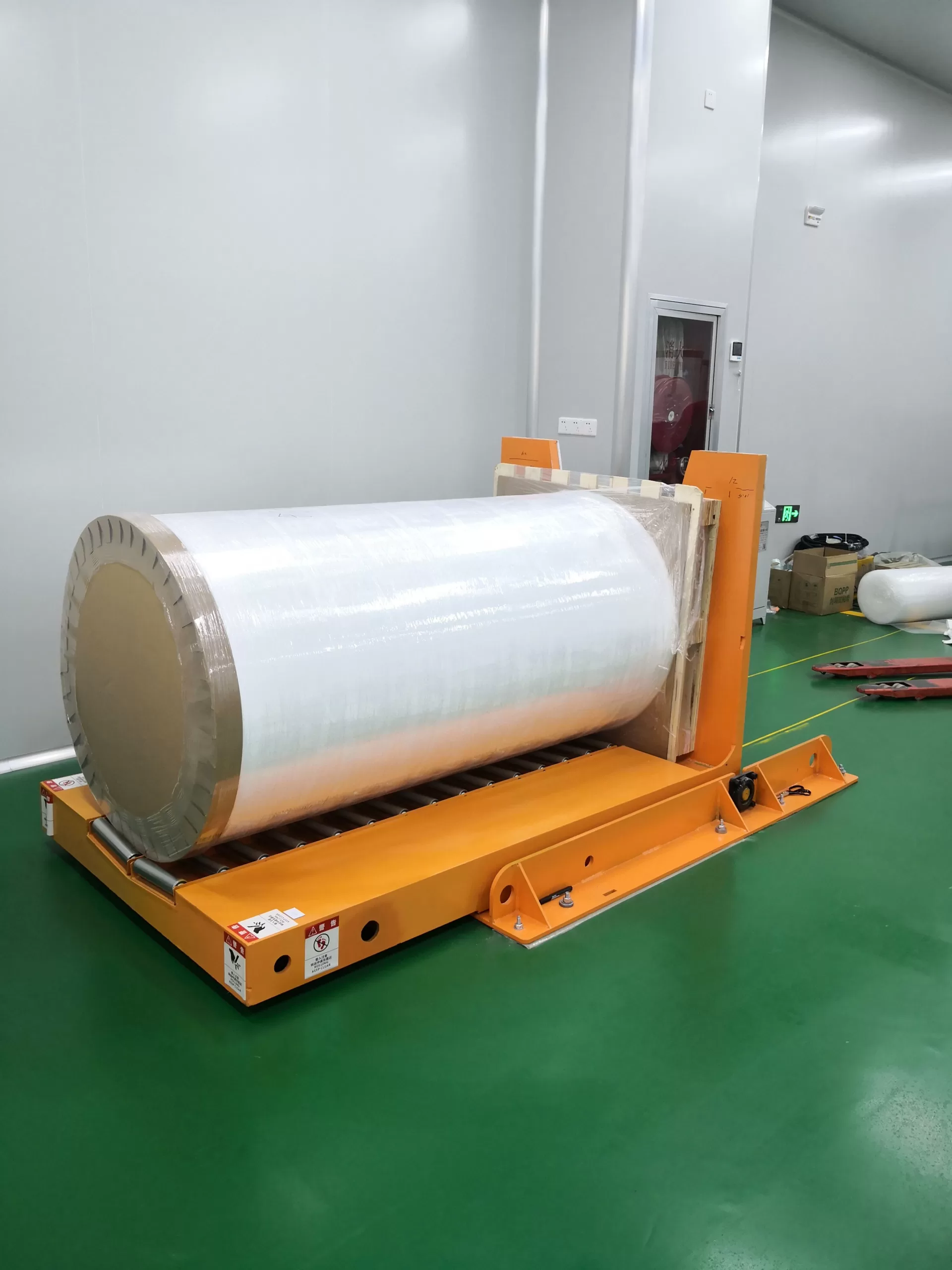

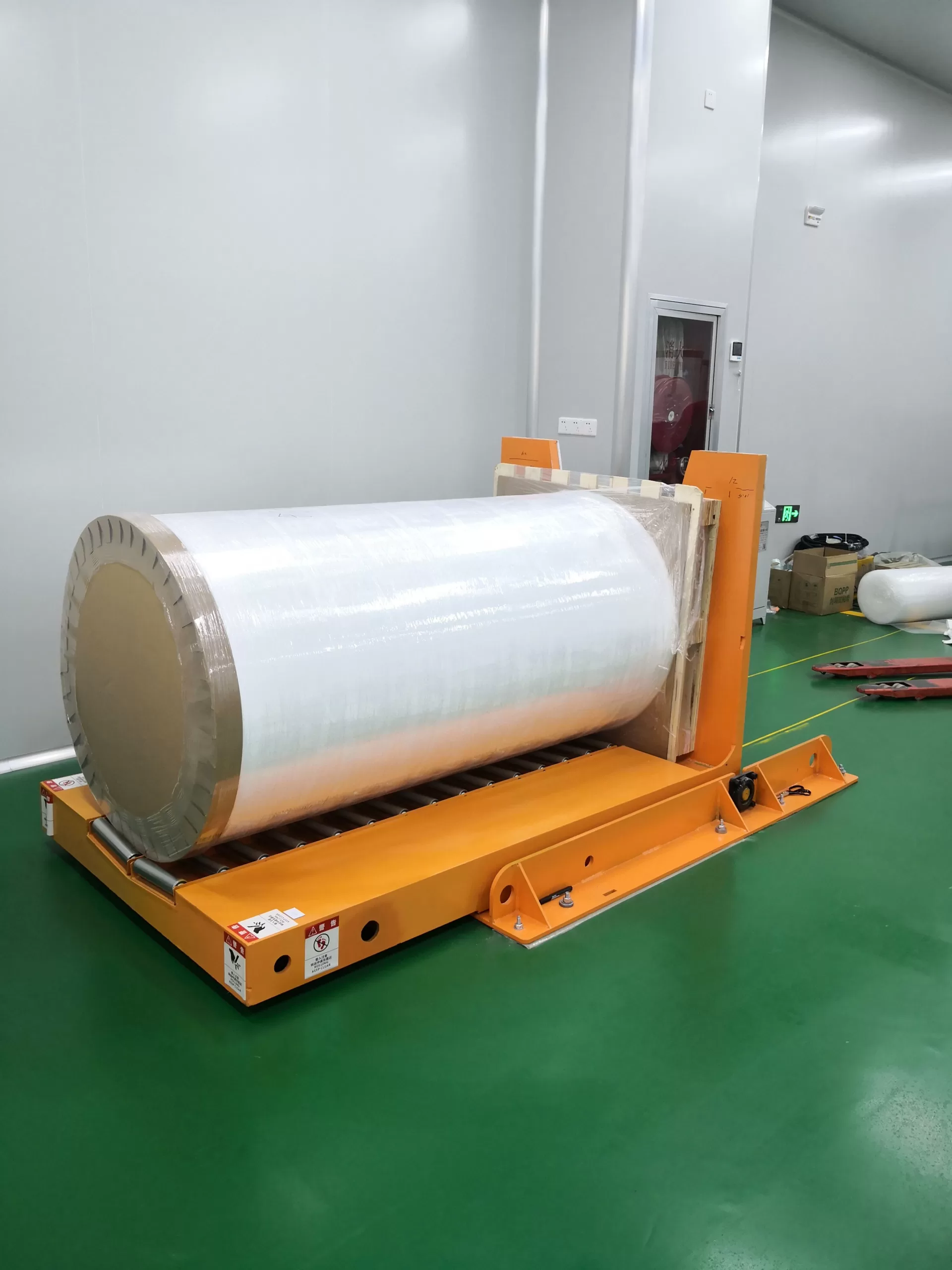

Paper Roll Upender

Project Information

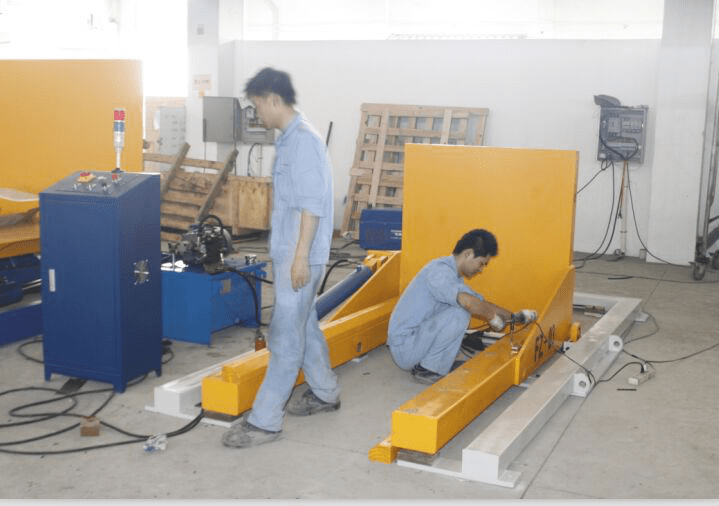

This hydraulic coil upender combines advanced functionality and robust design, making it indispensable for industries focused on safe and efficient heavy load handling. Its customizable features and reliable operation ensure improved productivity and safety.

Technical Parameters

Turning Capability:

90° rotation with dual-direction flexibility.

Maximum Capacity:

Supports loads up to 40 tons.

Customization:

Tailored to specific needs, ensuring compatibility with various industries.

Manual handling of heavy paper rolls risks damage, downtime, and operator injury. The Wuxi BuHui Paper Roll Upender tilts up to 2 000 kg loads 90° in just 10 seconds. Soft start/stop control and automatic position locks guarantee smooth, vibration-free tilting. An independent control panel keeps operators safely clear, while the robust design integrates seamlessly into demanding production lines.

The Challenge

- Operator Safety: Reduces risk by eliminating manual flips and forklift close-calls.

- Load Integrity: Prevents core deformation and punctures caused by abrupt movements.

- Cycle Consistency: Ensures repeatable 10 s tilts to stabilize throughput.

- Maintenance Burden: Minimizes downtime with smooth operation and built-in safety.

Solution: Features & Benefits

| Feature / Component | Benefit / ROI |

|---|---|

| 2 000 kg Capacity, C-Frame Design | Expands load range—handles large paper, carpet, or curtain rolls securely. |

| Hydraulic Drive & Soft Start/Stop | Delivers smooth 90° rotation in 10 s—reduces vibration and material stress. |

| Adjustable Speed via Inverter | Matches tilting time to line pace—stabilizes cycle times and boosts throughput. |

| Independent Electric Panel Control | Keeps operators at a safe distance with intuitive controls and emergency stop. |

| Mechanical & Electronic Position Lock | Automatically locks at any angle or on power loss—prevents unintended rotation. |

| Vibration-Free Motion | Protects roll integrity—lowers scrap rates and maintenance needs. |

| Robust Steel Structure & Low Maintenance | Maximizes uptime with a heavy-duty build and modular spare-parts kit. |

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | Paper Roll Upender |

| Load Capacity | Up to 2 000 kg |

| Tilt Angle | 90° |

| Cycle Time | Approx. 10 s per tilt |

| Power Supply | 220 V, 60 Hz, 3 Phase |

| Hydraulic Drive | 2.0 kW heavy-duty station |

| Control | Independent panel or remote; inverter speed control |

| Table Dimensions | Customizable; fits rolls Ø up to 1 000 mm |

| Safety Features | Emergency stop; mechanical & electronic restrictors |

| Noise Level | < 78 dB |

| Operating Environment | –50 °C to +40 °C; max. 3 mg/m³ dust |

| Maintenance Interval | Low maintenance; modular spare parts kit provided |

Ideal Applications & Industries

- Paper & Packaging Plants: Rapid reel changeovers with minimal labor.

- Carpet & Textile Manufacturers: Gentle handling of heavy fabric rolls.

- Automotive & Furniture Suppliers: Safe flipping of upholstery and curtain rolls.

- Printing & Converting Facilities: Streamlined roll handling in high-speed lines.

- Logistics & Warehousing: Secure roll manipulation for storage or shipment.

Why Wuxi BuHui?

- Fast, Reliable Throughput: Consistent 10 s tilt cycles at full capacity.

- Safety-First Design: Remote control, auto-locks, and restrictors protect operators.

- Precision & Durability: Vibration-free hydraulics preserve roll integrity.

- Customizable & Low-Maintenance: Modular build adapts to roll dimensions.

- Energy-Efficient: Optimized hydraulic and inverter systems lower power use.

Contact Us for a Customized Quote

Ready to revolutionize your roll-handling process? Contact us today for a tailored quotation on the Wuxi BuHui Paper Roll Upender solution!

The Hydrauliccoil upender machine is a custom-designed flat tilter that can handle a load of up to 40Tmold. The upending process involves raising one half of the upender to 90 degrees, loading the tool against the raised half, and then simultaneously rotating both halves to rotate or upend the tool by 90 degrees for servicing.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

Roll upender

Roll upender is a machine used for handling large rolls of paper, curtain, and carpet, it has a heavy-duty and durable st

View DetailsHydraulic upender

A floor base hydraulic upender/tilter is a machine that is used to rotate heavy objects during operations. It has a stabl

View Details