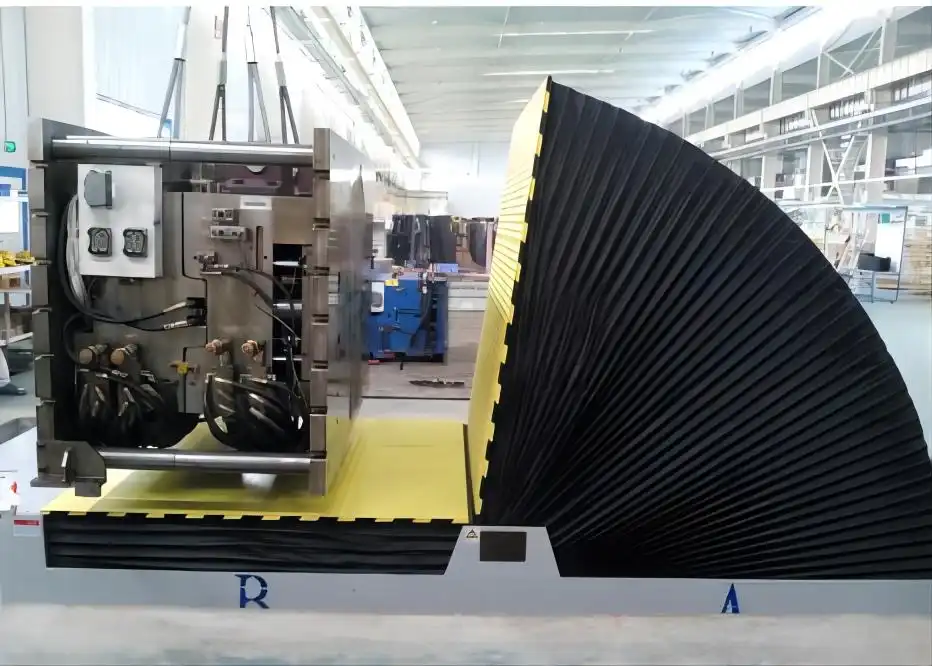

90 Degree Mold Upender 10T

Project Information

The 90-Degree Mold Upender 10T is engineered to flip molds up to 10 tons with unparalleled precision and safety. Its robust hydraulic system and durable steel construction streamline mold repositioning in manufacturing, minimizing downtime and manual risks. This versatile equipment is ideal for large-scale operations prioritizing efficiency and safety.

Maximum Load Capacity: 10 Tons (10,000 Kg)

Rotation Angle: 90 Degrees

Material: High-Strength Steel

Motor Power: 3.5 kW

Dimensions (L x W x H): 3000 x 2000 x 500 mm

Accelerate Mold Change-over with the 90° Mold Upender

Manual mold flips are slow, risky, and imprecise. Wuxi BuHui’s 90° Mold Upender hydraulically rotates up to 10 tons of mold steel smoothly and safely—slashing downtime, protecting your crew, and delivering repeatable, vibration-free motion.

Production Challenges

- Extended downtime from manual handling

- Operator injury risk when lifting heavy molds

- Inaccurate positioning without precision controls

- Stress and wear on fixtures from manual overturning

Features & Benefits

| Feature | Benefit / ROI |

|---|---|

| Hydraulic 90° Flip up to 10 T | Eliminates manual lifting—speeds mold change-over |

| High-Strength Steel Frame | Withstands harsh shop conditions—ensures longevity |

| Adjustable Speed & Soft Start/Stop | Matches your cycle time—protects molds and tooling |

| Photo-Electric Sensors & Position Lock | Delivers exact, repeatable 90° positioning |

| Remote & Panel Controls | Simplifies operation—cuts training time |

| Vibration-Free, Smooth Motion | Prevents damage—ensures consistent quality |

| Automatic Fault Detection | Stops on error—safeguards equipment and operators |

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | 90 Degree Mold Upender 10T |

| Maximum Load Capacity | 10 000 kg (10 T) |

| Rotation Angle | 90° |

| Motor Power | 7.5 kW |

| Hydraulic Oil Capacity | 15 L |

| Table Dimensions (L×W×H) | 3000 × 2000 × 500 mm |

| Frame Material | High-strength steel |

| Control System | Hydraulic drive, manual/remote panel |

| Cycle Time | 60–90 sec per flip |

| Power Supply | 380 V / 3 Phase |

| Safety Standards | CE compliant, emergency stop features |

Ideal Applications & Industries

- Injection Molding Shops – Rapid mold maintenance and change-over

- Die Casting Facilities – Safe handling of heavy dies

- Rubber & Plastics Production – Frequent mold repositioning

- Metal Stamping Plants – Precise part flipping for inspection

- Maintenance & Tool Rooms – Ergonomic servicing station

Why Wuxi BuHui?

- Precision & Safety First: Photo-electric sensing ensures perfect flips every time.

- Robust Reliability: Heavy-duty steel and premium hydraulics for years of trouble-free operation.

- Operator-Friendly: Intuitive controls reduce training and boost throughput.

- Flexible Integration: Compact footprint and adjustable speed fit any line.

- Comprehensive Support: Expert installation, training, and preventive maintenance.

Request a Quote

Ready to eliminate mold change-over delays and protect your team? Contact Wuxi BuHui today for custom drawings, competitive pricing, and a tailored 90° Mold Upender solution.

A 90-degree mold upender with a 10-ton capacity is an industrial solution designed for safe and efficient handling of heavy molds. It simplifies mold rotation, enhances workplace safety, and reduces manual labor. Ideal for manufacturing operations, it ensures precision, durability, and reliability in mold flipping processes.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

Die and Mold Turner

A die and mold turner is a specialized machine designed to safely and efficiently rotate heavy dies and molds. It enhance

View Details180 Degree Mold Upender 5T

The 180 Degree Mold Upender 5T is a robust and efficient solution designed to safely and seamlessly rotate heavy molds up

View Details180 Degree Mold Upender 20T

The 180 Degree Mold Upender 20T is a heavy-duty machine designed to safely and efficiently rotate molds or materials up t

View Details90 Degree Mold Upender 20T

The 90 Degree Mold Upender 20T is a robust and efficient machine designed for safely flipping heavy molds up to 20 tons.

View Details90 Degree Mold Upender 5T

The 90-Degree Mold Upender 5T is a reliable and efficient solution for safely tilting heavy molds up to 5 tons. Designed

View Details90 Degree Mold Upender 40T

The 90-degree mold upender 40T is a reliable industrial machine designed to rotate heavy molds up to 40 tons with precisi

View Details