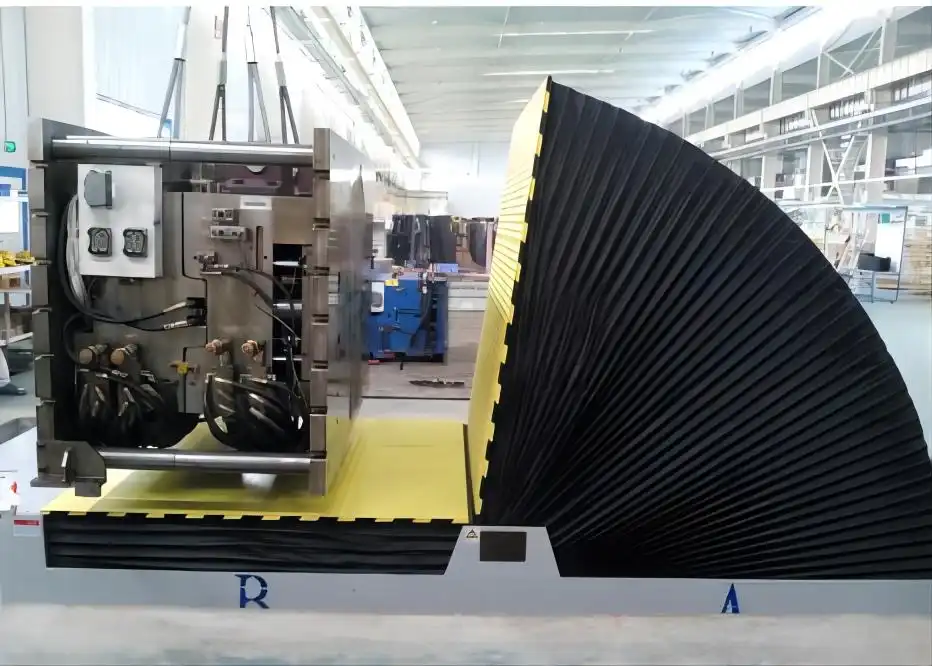

Die and Mold Turner

Project Information

Die and mold turners have revolutionized the handling of heavy components, addressing challenges such as safety risks and operational inefficiencies. By automating the flipping and positioning of dies and molds, these machines reduce manual labor, enhance precision, and ensure worker safety.

Efficiency: Reduces downtime with streamlined operations.

Safety: Minimizes risks of manual handling heavy loads.

Labor Optimization: Allows workers to focus on high-value tasks.

Wuxi BuHui’s Die & Mold Turner automates 180° flips of multi-ton tooling, replacing manual handling with a robust, precision hydraulic solution. Operators enjoy consistent cycle times, fewer errors and a safer shop floor—all in a compact footprint that fits existing workflows.

The Challenge: Manual Handling Risks

- Operator Safety: Lifting 5–40 ton molds by hand risks injuries.

- Throughput Delays: Inconsistent flips cause bottlenecks and scrap.

- Tooling Damage: Improper handling leads to costly mold repairs.

The Solution: Key Features & Benefits

| Feature | Benefit / ROI |

|---|---|

| Hydraulic 180° Rotation | Delivers smooth, repeatable flips—eliminates manual strain and errors |

| Heavy-Duty Steel Frame | Withstands rigorous use for long service life |

| Dual Control Modes | Integrates with PLC systems or runs standalone for flexible deployment |

| Safety Locks & E-Stop | Guards operators and prevents accidental movement |

| Adjustable Table Height | Adapts to different mold sizes—speeds up changeovers |

Technical Specifications

| Specification | Details |

|---|---|

| Model | FPMT-5 / FPMT-20 / FPMT-40 |

| Max Load | 5 ton / 20 ton / 40 ton |

| Rotation Angle | 180° |

| Drive System | Hydraulic (optional electric controls) |

| Frame Material | High-strength industrial steel |

| Control | Manual panel & PLC interfaces |

| Motor Power | 7.5 kW |

| Hydraulic Oil | 15 L capacity |

| Dimensions | Table L×W×H varies by model |

Ideal Applications & Industries

- Injection Molding: Fast mold changes for automotive & consumer goods

- Die Casting: Safe flipping of aluminum and zinc dies

- Tool & Die Shops: Precision orientation for maintenance & repair

Why Choose Wuxi BuHui?

Our solution blends industrial-grade durability, precision hydraulics and layered safety controls. Backed by responsive support and customization, it drives measurable reductions in downtime, labor expenses and safety incidents—delivering ROI from day one.

Request a Quote

Ready to upgrade your mold-handling process? Contact us to discuss capacity, layout integration and custom options. Discover how our Die & Mold Turner can boost safety, speed and productivity on your production line!

A die and mold turner is a specialized machine designed to safely and efficiently rotate heavy dies and molds. It enhances workplace safety by reducing manual handling risks and ensures precise positioning during maintenance or production processes, making it an essential tool for industrial applications.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

180 Degree Mold Upender 5T

The 180 Degree Mold Upender 5T is a robust and efficient solution designed to safely and seamlessly rotate heavy molds up

View Details180 Degree Mold Upender 20T

The 180 Degree Mold Upender 20T is a heavy-duty machine designed to safely and efficiently rotate molds or materials up t

View Details90 Degree Mold Upender 20T

The 90 Degree Mold Upender 20T is a robust and efficient machine designed for safely flipping heavy molds up to 20 tons.

View Details90 Degree Mold Upender 5T

The 90-Degree Mold Upender 5T is a reliable and efficient solution for safely tilting heavy molds up to 5 tons. Designed

View Details90 Degree Mold Upender 40T

The 90-degree mold upender 40T is a reliable industrial machine designed to rotate heavy molds up to 40 tons with precisi

View Details90 Degree Mold Upender 10T

A 90-degree mold upender with a 10-ton capacity is an industrial solution designed for safe and efficient handling of hea

View Details