Tired of Manual Handling Inefficiencies and Safety Concerns?

Discover how our industrial-grade hydraulic box dumpers transform your material handling operations with precision engineering and enhanced safety features.

Boost Operational Efficiency

Automated hydraulic dumping cycles process materials 3x faster than manual methods, maximizing throughput.

Enhanced Worker Protection

Eliminate heavy lifting injuries with our secure containment systems and controlled dumping mechanisms.

Versatile Material Handling

Handle various container sizes and materials with adjustable hydraulic pressure and customizable platforms.

Reduced Operational Costs

Cut labor expenses and minimize product loss with precise, repeatable dumping cycles and minimal maintenance.

Join hundreds of manufacturing facilities worldwide that have upgraded their material handling systems.

Request Your Custom Solution

Project Overview & Advantages

Explore our specialized capabilities and successful case studies across various manufacturing sectors

Hydraulic Dumper Manufacturing Excellence

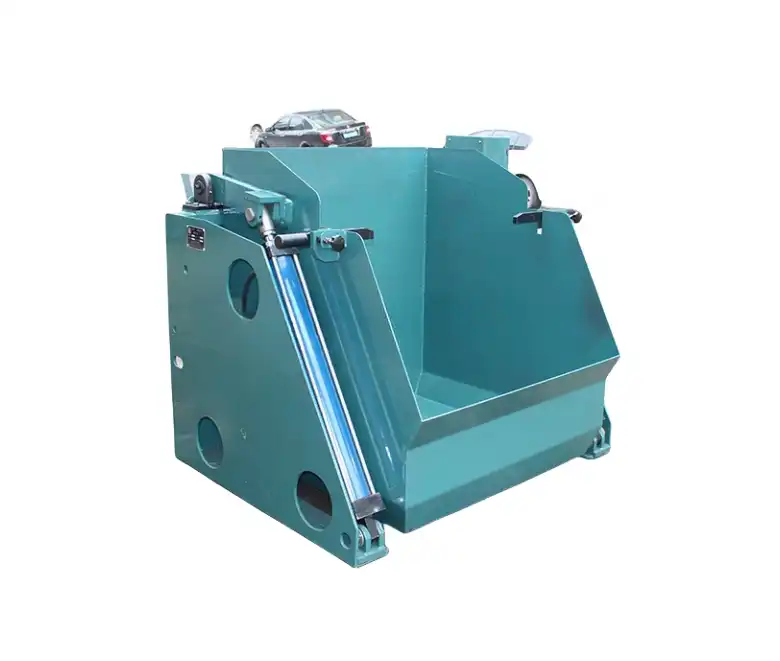

Wuxi BuHui’s Hydraulic Dumper delivers effortless elevation and tipping of heavy boxes and containers—streamlining your workflow, boosting throughput, and enhancing operator safety with smooth, reliable performance.

Mechanical upender

Discover affordable solutions for handling heavy materials with our mechanical coil upender, coil tilter, and mold upending machine. Designed for efficiency and safety, these machines simplify operations while reducing costs. Perfect for industries needing reliable equipment without breaking the budget. Upgrade your workflow today with our competitively priced, high-performance machinery tailored

Hydraulic upender

A hydraulic upender is an industrial machine designed to safely and efficiently tilt or rotate heavy loads, such as steel coils, molds, or other bulky items. Using hydraulic power, it ensures precise handling, reduces labor strain, and enhances workplace safety. Its robust construction and customizable features make it ideal for manufacturing, warehousing, and heavy-duty operations.

Coil Upender

Find reliable solutions for heavy material handling with our coil upender, designed to improve efficiency and safety in industrial operations. Partner with a trusted coil upender manufacturer to ensure high-quality, durable equipment tailored to your specific needs. Enhance your workflow today with innovative and cost-effective solutions for your business.

Mold Upender

Enhance your mold handling operations with our mold upender, mold tilter, and mold turning machine. Designed for precision and safety, these machines simplify the process of tilting and rotating heavy molds. Ideal for various industries, they improve efficiency, reduce labor effort, and ensure smooth operations. Invest in reliable, high-performance equipment tailored to your production needs.

Mold Flipper

A mold flipper is a specialized machine designed to rotate or flip molds safely and efficiently during manufacturing processes. It reduces manual handling, minimizes the risk of damage to molds, and improves workplace safety. With its precise and reliable operation, a mold flipper is essential for industries working with heavy or complex molds.

Hydraulic Dumper

Wuxi BuHui’s Hydraulic Dumper delivers effortless elevation and tipping of heavy boxes and containers—streamlining your workflow, boosting throughput, and enhancing operator safety with smooth, reliable performance.

Heavy-Duty Hydraulic Box Dumper Systems

Our industrial-grade hydraulic box dumpers revolutionize material handling operations with powerful lifting capabilities and precision control engineering. Designed for demanding warehouse and manufacturing environments, these systems eliminate manual lifting risks while optimizing workflow efficiency.

Precision Hydraulic Control: Smooth, controlled dumping action with adjustable tilt angles up to 90 degrees for complete material discharge.

Enhanced Safety Features: Integrated safety locks, emergency stop systems, and overload protection for secure industrial operation.

Customizable Configurations: Available in multiple sizes and capacities from 500kg to 5000kg to match specific operational requirements.

Manual Labor Reduction

Workplace Injury Prevention

Throughput Improvement

Maximum Load Capacity

Automotive Parts Manufacturer Streamlines Material Handling

Operational Challenge

A leading automotive components facility faced significant ergonomic challenges with manual box handling, experiencing frequent worker injuries and inconsistent production flow. Their existing process required multiple operators to lift and empty heavy component boxes into processing equipment.

Engineering Solution

We implemented a customized hydraulic dumper system with automated height adjustment and programmable controls. The installation eliminated manual lifting entirely, reduced processing time per box by 65%, and achieved full ROI within 8 months through reduced labor costs and injury-related expenses.

Request Custom Solution Analysis

SHOWCASE & NEWS

Hydraulic Box Dumper Solutions: Your Questions Answered

Expert Insights on Heavy-Duty Material Handling and Industrial Dumping Equipment

Hydraulic box dumpers are essential for numerous material handling operations across multiple industries. They excel in manufacturing facilities, recycling plants, food processing operations, and chemical processing plants where efficient bulk material transfer is crucial. These robust systems handle everything from raw materials and finished products to waste management and recycling materials. Their versatile design makes them ideal for automated production lines, warehouse operations, and distribution centers throughout North America and global markets.

Our hydraulic dumping equipment incorporates advanced safety engineering with precision control systems. The integrated hydraulic circuit features pressure relief valves, check valves, and pressure-compensated flow controls that ensure smooth, controlled lifting and lowering motions. This eliminates sudden movements that could cause material spills or equipment damage. The system maintains consistent operation even under maximum 6-ton loads, providing reliable performance that reduces workplace accidents and protects both operators and materials throughout the dumping cycle.

We offer comprehensive customization to match your specific material handling requirements. Our hydraulic dumpers feature adjustable retaining bars with 50mm increment positioning to accommodate various container heights. Standard models handle rotated heights from 2743mm to 3760mm, with capacity options of 2, 4, and 6 tons. For specialized applications, we can engineer custom solutions for unusual container dimensions, specific weight distributions, or unique operational environments, ensuring perfect integration with your existing workflow and equipment layout.

Proper maintenance is straightforward yet crucial for long-term reliability. Daily visual inspections and basic cleaning require approximately 10-15 minutes. Weekly maintenance includes hydraulic system checks and structural integrity verification (30-45 minutes). Monthly comprehensive maintenance involves detailed inspection of welded joints, hydraulic components, and safety systems (2-3 hours). We provide detailed maintenance manuals and optional service contracts. With proper care, our all-welded steel construction ensures equipment lifespan exceeding 15 years, even in demanding industrial environments with continuous operation.

Our safety-first engineering incorporates multiple protective features. Meshed side screens prevent access to moving parts during operation, while the adjustable retaining bar securely contains containers throughout the dumping process. The system includes emergency stop buttons, multiple safety interlocks, and failsafe hydraulic controls that prevent accidental operation. By automating the heavy lifting and tilting motions, we eliminate manual handling risks, reducing workplace injuries by up to 85% compared to manual dumping methods. These comprehensive safety measures protect both personnel and equipment investment.

Our hydraulic dumpers feature seamless integration capabilities for modern industrial automation. They compatible with PLC control systems, conveyor interfaces, and robotic material handling equipment. Standard models include multiple I/O connection points for automated triggering, position feedback, and system status monitoring. For advanced operations, we offer integration with plant-wide monitoring systems, production tracking software, and safety networks. Our engineering team works directly with your automation specialists to ensure smooth integration that enhances your overall material handling efficiency and production throughput.

Our Clients Around The World

We are honored to serve outstanding enterprises worldwide, establishing long-term stable partnerships. Below are some of our trusted partners who have chosen our manufacturing solutions.

Ready to Start Your Next Manufacturing Project?

Impressed by our projects? If you have similar requirements or want to discuss your project ideas, contact our expert team immediately for a free initial consultation.

Contact Our Experts