Tired of Inefficient Wire Bundling Processes?

Discover how our automated wire compacting and strapping technology eliminates packaging bottlenecks while ensuring superior bundle integrity for your wire products.

Loose Bundling & Stability Issues

Manual wire compacting results in unstable bundles that come apart during handling and shipping.

Excessive Material Usage

Inefficient strapping methods waste significant packaging materials and increase operational expenses.

Throughput Limitations

Slow packaging speeds create production bottlenecks that delay order fulfillment and shipments.

Inconsistent Bundle Quality

Variable packaging results lead to customer complaints and potential product damage claims.

Project Overview & Advantages

Explore our specialized capabilities and successful case studies across various manufacturing sectors

Wire compacting and strapping line Manufacturing Excellence

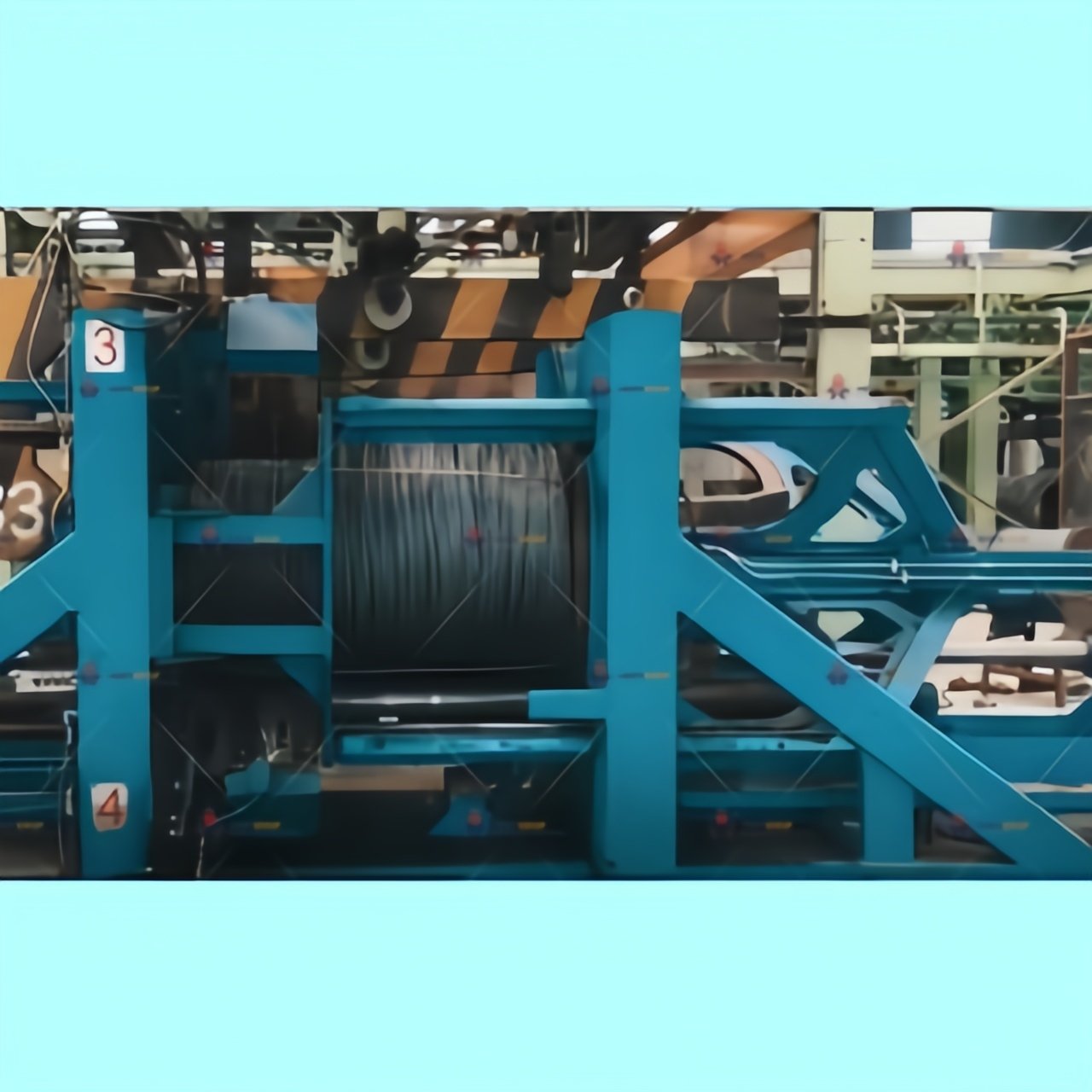

A Wire Compacting and Strapping Line is a specialized system designed to compact and securely strap wire coils or bundles. It ensures precise alignment, efficient compression, and durable strapping for easy handling and transport. This automated solution enhances productivity, reduces labor costs, and guarantees safe and reliable packaging for industrial wire products.

Wire winding and packing line

The solution of the Automatic steel wire rewinding and packaging lines that includes the wire rewiding, wire strapping, wire coil wrapping and package stacking. The solution is customzied per different steel wire factory

Wire compacting and strapping line

A Wire Compacting and Strapping Line is a specialized system designed to compact and securely strap wire coils or bundles. It ensures precise alignment, efficient compression, and durable strapping for easy handling and transport. This automated solution enhances productivity, reduces labor costs, and guarantees safe and reliable packaging for industrial wire products.

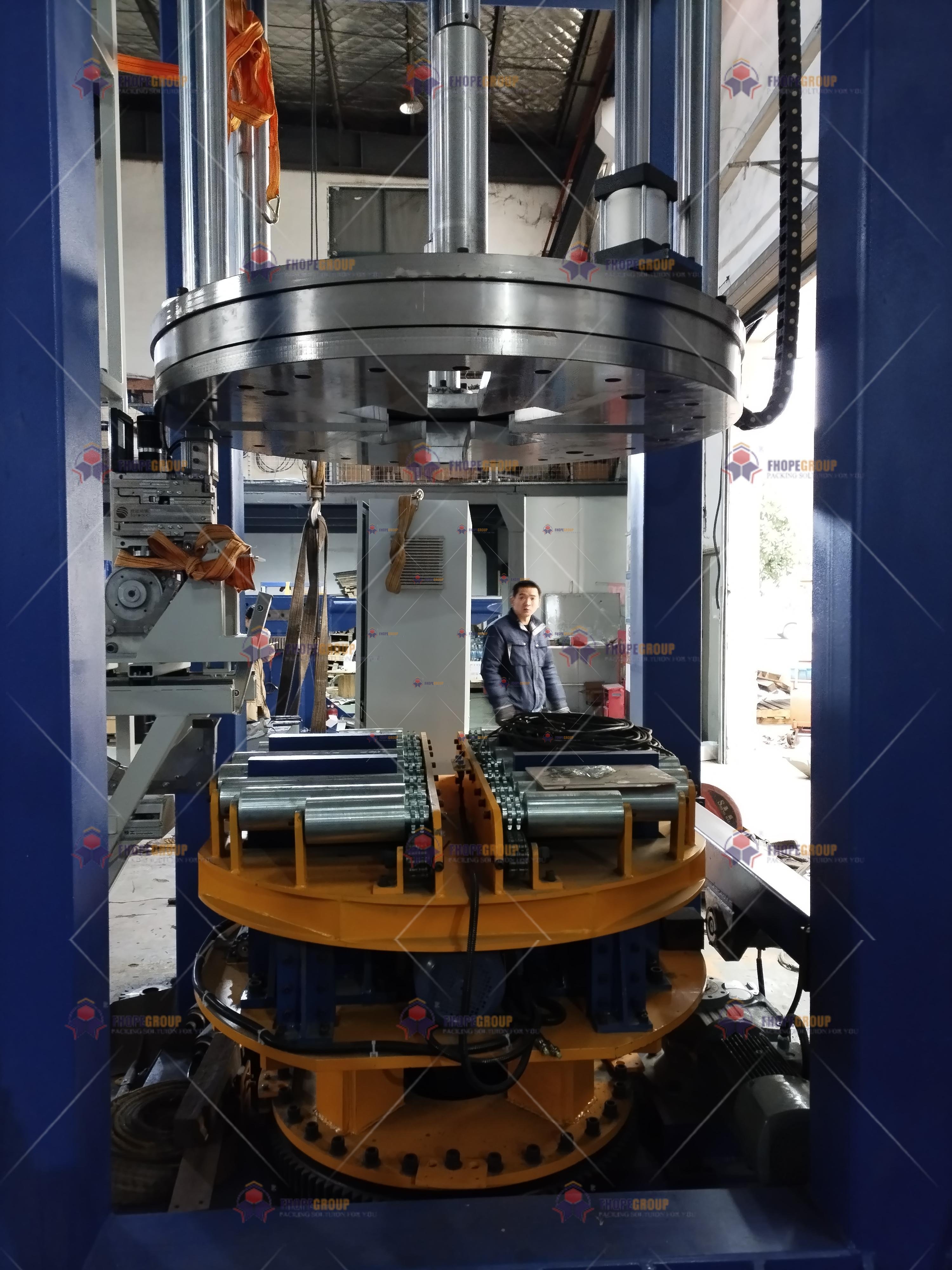

Automated Wire Compacting & Strapping Systems

Fhope's innovative wire compacting and strapping solutions deliver precision-engineered automation for superior bundle integrity and transport security. Our systems eliminate manual handling inconsistencies while optimizing material usage across various wire types and diameters.

Precision Tension Control: Advanced servo-driven systems maintain consistent strapping force, preventing wire deformation while ensuring bundle stability.

Adaptive Compression Technology: Intelligent pressure adjustment accommodates varying wire densities and bundle sizes from 50mm to 1200mm diameters.

Multi-Material Compatibility: Engineered to handle steel, copper, aluminum, and specialty alloy wires with customized strapping patterns.

Space Optimization in Storage

Reduction in Packaging Time

Bundle Consistency Rate

Material Waste Reduction

Wire Manufacturing Giant Achieves Packaging Automation Breakthrough

Operational Challenges

A leading European wire producer struggled with manual bundling processes causing inconsistent package density, shipping damage claims, and rising labor costs. Their existing equipment couldn't handle diverse product specifications efficiently.

Fhope's Integrated Solution

We implemented a fully automated compacting and strapping line featuring smart density calibration and robotic bundle handling. The results: 280 bundles per hour output capacity, 85% reduction in shipping damage incidents, and ROI achieved within 14 months of operation.

Request Your Custom Solution

SHOWCASE & NEWS

Wire Compacting and Strapping Line FAQ

Expert Answers to Your Wire Packaging Equipment Questions

Automated wire compacting systems revolutionize traditional bundling by delivering precise compression and consistent bundle density. Unlike manual methods that vary in tightness, our machinery ensures uniform compaction that prevents wire deformation while maximizing storage efficiency. The advanced technology reduces labor requirements by up to 70% and increases processing speed by 3-4 times compared to conventional techniques.

Our strapping systems incorporate specialized tension control and surface-friendly materials that eliminate wire damage. The technology features adjustable pressure settings, smooth contact surfaces, and protective coatings that prevent scratching or indentation. For delicate copper and aluminum wires, we recommend polymer strapping that distributes pressure evenly while maintaining bundle integrity across long-distance shipments and harsh environmental conditions.

Our compacting solutions handle an extensive range of wire specifications, accommodating diameters from 0.5mm to 12mm across various materials. The systems efficiently process copper wire, aluminum cables, steel wire ropes, and specialty alloys. Custom configurations support different bundle weights from 5kg to 200kg, with optional features for coated wires, multi-strand cables, and temperature-sensitive materials that require gentle handling.

Absolutely. Our wire packaging systems are designed for seamless integration with existing production lines. We provide compatibility with drawing machines, annealing equipment, spoolers, and coiling systems through standardized interfaces. The modular design allows for flexible configuration, while our engineering team ensures smooth connectivity with your current material handling systems and production workflow, minimizing disruption during installation.

Automated wire compacting and strapping delivers substantial operational savings, typically achieving 40-60% reduction in packaging labor costs. Material usage optimization decreases consumable waste by 25-35%, while consistent bundle density reduces shipping volume by 15-20%. Most clients recover their investment within 18 months through increased output, reduced damage claims, and lower workforce requirements, with ongoing annual savings of $50,000-$150,000 depending on production volume.

We provide comprehensive post-installation support including on-site operator training, maintenance workshops, and 24/7 technical assistance. Our package includes detailed operation manuals, video tutorials, and remote diagnostics capabilities. Customers receive dedicated account management, regular service check-ups, and priority access to spare parts. For international clients, we maintain regional service centers in key industrial markets to ensure prompt response times and localized support.

Our Clients Around The World

We are honored to serve outstanding enterprises worldwide, establishing long-term stable partnerships. Below are some of our trusted partners who have chosen our manufacturing solutions.

Ready to Start Your Next Manufacturing Project?

Impressed by our projects? If you have similar requirements or want to discuss your project ideas, contact our expert team immediately for a free initial consultation.

Contact Our Experts