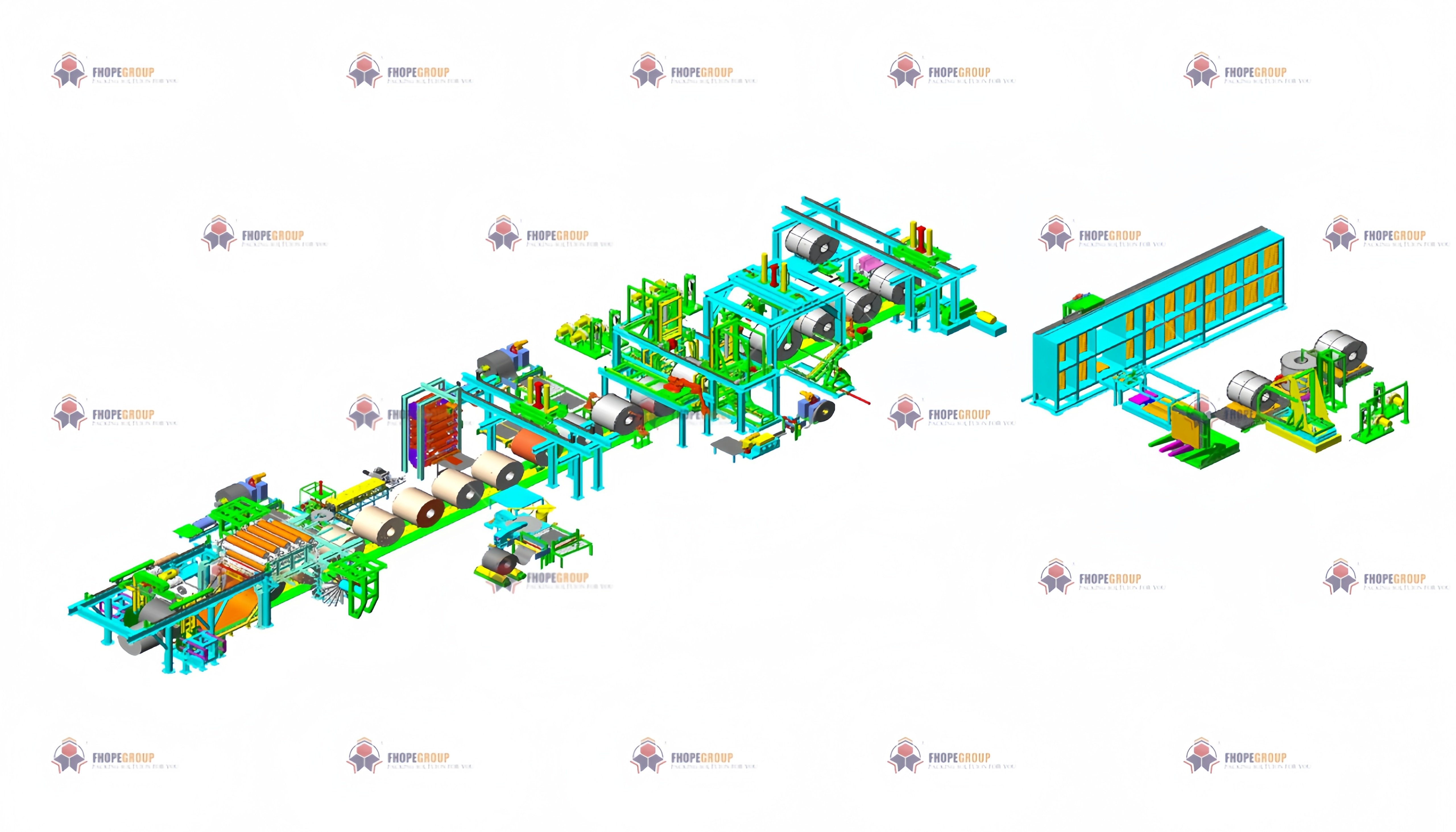

Automated Steel Coil Packaging line

Project Information

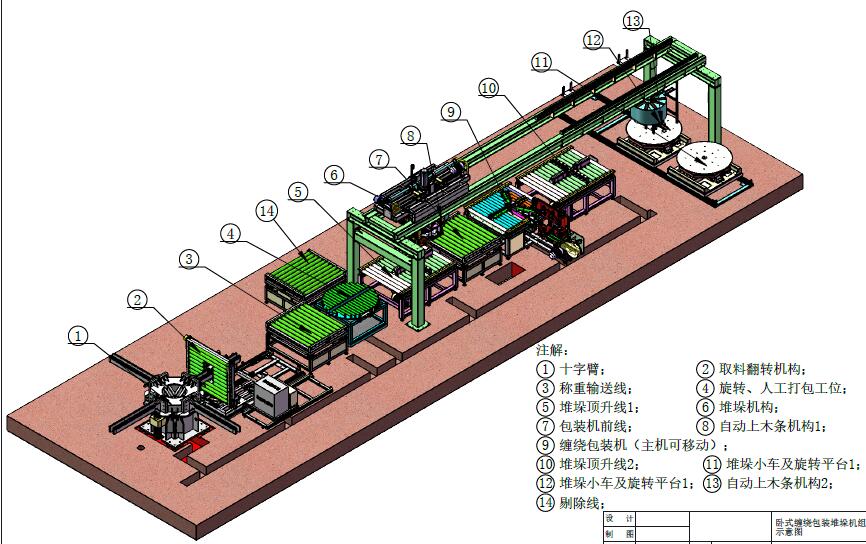

The Automated Steel Coil Packaging Line is a new system designed for the seamless connecting with slitting line for coil handling, wrapping, and strapping of steel coils. Integrating advanced PLC controls, conveyors, and strapping stations, it optimizes packing processes with unmatched speed and consistency. This solution minimizes manual labor, enhances safety, and protects steel coils during transit and storage.

Key Parameters:

Coil Dimensions: OD 700–1600 mm, ID 508-610 mm, Width 20–500 mm

Weight Capacity: 100–5000 kg per coil

Packing Speed: 20–40 coils/hour

Power Supply: 380V, 3-phase, 50 Hz (can be customizied)

Automation: PLC and SCADA-based operation for precision control

Wuxi BuHui’s Automatic Steel Coil Packaging Line integrates coil loading, upending, strapping, wrapping, powered conveyors, stacking and pallet wrapping under PLC/HMI control—delivering 20–30 coils/hour throughput with minimal labor, consistent quality, and maximum uptime.

The Challenge: Coil Packaging Bottlenecks

- High labor & safety risk: Manual handling of 100–3,000 kg slit coils inflates costs and hazards.

- Throughput mismatch: Slitting rates exceed manual packaging capacity, causing bottlenecks.

- Quality inconsistency: Variable strap tension and wrap overlap compromise coil security.

- Integration complexity: Coordinating turnstile, upender, strapping, wrapping, conveyors and stacking demands precise logic.

- Material management: Rapid changeovers for film, paper, straps risk waste and delays.

- Control complexity: Inadequate automation leads to downtime and manual recovery.

- Energy & maintenance: Multiple drives and pneumatics drive up OPEX and downtime.

- Deployment pressure: Quick install and ROI are essential to avoid production delays.

- Plant constraints: Must operate reliably at 0–40 °C, ≤75 dB, 0.6–0.8 MPa air without impacting adjacent lines.

Solution: Features & Benefits

| Feature / Component | Benefit / ROI |

|---|---|

| PLC/HMI Central Control | Quick recipe changes, real-time monitoring, secure data logging for consistent operation. |

| Turnstile / Coil Car Interface | Safe, synchronized coil transfer from slitter—no manual handoffs. |

| Automatic Upender | Controlled rotation between horizontal/vertical positions—protects coil & personnel. |

| Strapping Module | Consistent belt tension, fast material changeover, secure load stabilization. |

| Wrapping Station | Stretch film or VCI paper with adjustable overlap/tension for uniform protection. |

| Powered Conveyors | Inverter-driven, PLC-synced conveyors handle up to 3 000 kg—eliminates stops. |

| Stacking & Pallet Wrapping | Automated stacking and pallet wrap—reduces manual labor, speeds dispatch. |

| Fault Detection & Alarms | Immediate stops and alerts on misfeeds, strap breaks, or film tears—minimizes rework. |

| Multi-Material Compatibility | Supports film, paper, composite wraps and various straps—quick-change mechanisms cut waste. |

| High Throughput | 20–30 coils/hour matches slitting output—prevents backlogs. |

| Energy-Efficient Drives | Inverter motors & efficient pneumatics lower power and air use. |

| Modular Layout | Flexible station arrangement and bypass options adapt to any floorplan. |

| Robust Design & Access | Heavy-duty frames and service panels simplify maintenance and uptime. |

| Rapid Commissioning | Engineering support, detailed layouts, and quick hook-up accelerate ROI. |

Technical Specifications

| Parameter | Specification |

|---|---|

| Coil Weight | 100–3 000 kg per coil |

| Coil OD | 900–1 400 mm |

| Coil Width | 15–450 mm |

| Speed | 20–30 coils/hour |

| Power | AC 380 V, 3 phase, 50 Hz |

| Control | Siemens PLC + MSGC HMI |

| Air | 0.6–0.8 MPa clean, dry air |

| Materials | Stretch film, VCI paper, composite films, straps |

| Environment | 0–40 °C ambient, ≤75 dB noise |

| Safety | Guarding, interlocks, light curtains, E-stops |

Request a Quote

Ready to streamline your slit-strip coil packaging? Contact Wuxi BuHui for a tailored configuration, engineering drawings, and competitive pricing.

The Steel Coil Packaging Line is an industrial solution tailored to efficiently package steel coils with precision and safety. This automated system handles strapping, wrapping, and securing coils, reducing labor costs and safeguarding products during transport. It’s an ideal choice for high-volume operations seeking reliability and protection for their steel products.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

Automatic Steel Coil Strapping

The Automatic Steel Coil Strapping Line is a cutting-edge solution designed for efficient and secure steel coil packaging

View DetailsAutomatic Steel Coil Packing Sy

The automatic steel coil strapping package line provides a reliable solution for securing steel coils with precision and

View DetailsCold Roll Steel Coil Strapping

A Cold Roll Steel Coil Strapping & Packing Line Manufacturer specializes in efficient, durable strapping and packaging so

View DetailsStainless Steel Coil Packing Li

The stainless steel coil packing line is designed to efficiently secure and protect stainless steel coils during transpor

View DetailsSlit Coil Handling and Packagin

A stainless steel coil packing line streamlines the packaging process, providing consistent, high-quality protection for

View Details