Slit Coil Handling and Packaging Line

Project Information

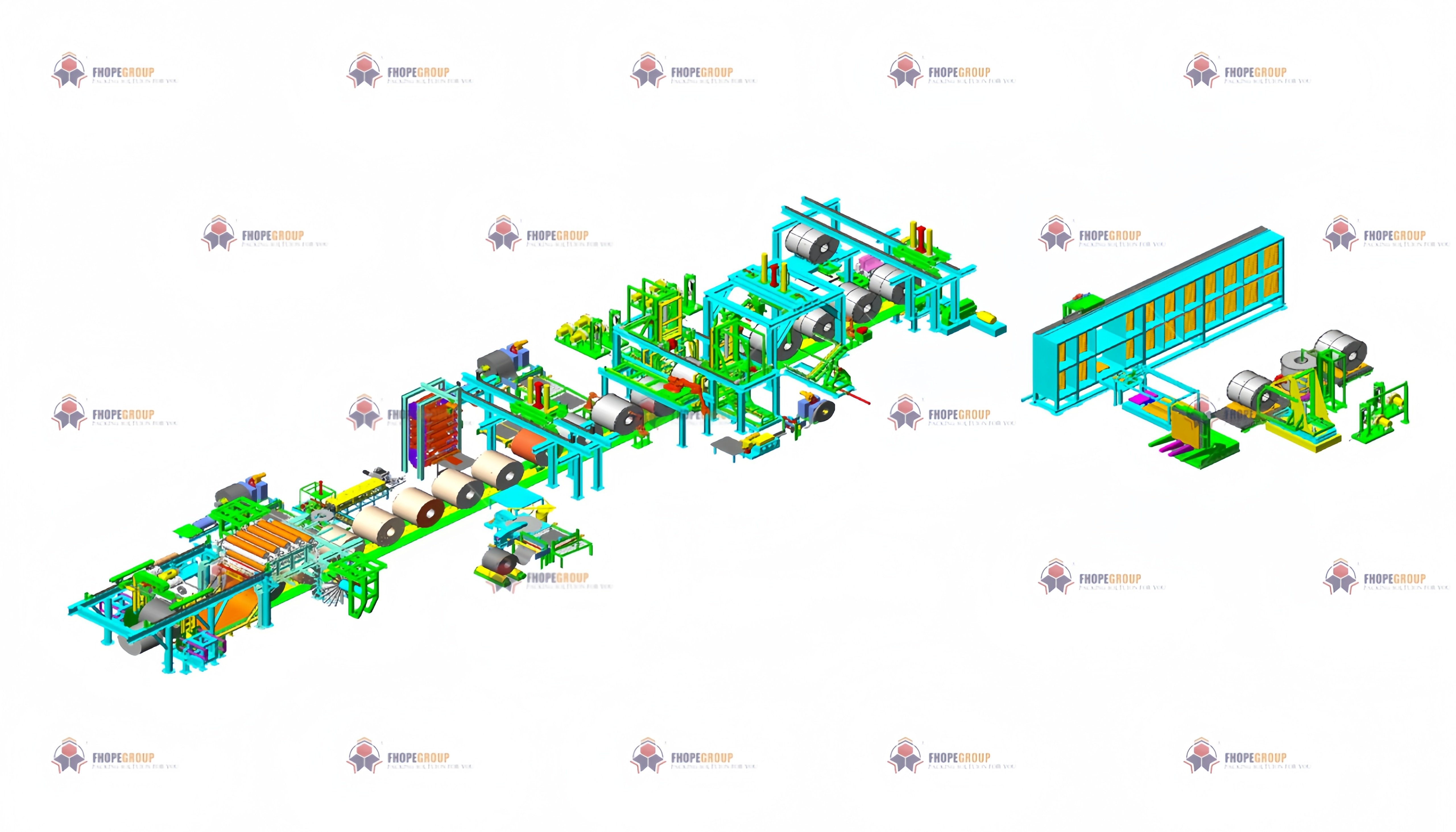

The slit coil handling and packaging line is an essential system designed to optimize the transportation, stacking, and secure packaging of slit coils in industrial operations. It integrates automation to enhance efficiency, reduce manual labor, and ensure the precision handling of heavy-duty coils. This solution is tailored to meet diverse production requirements, focusing on safety, speed, and durability. By leveraging advanced technologies, it ensures minimal coil damage, streamlined workflows, and compliance with industry standards, making it an invaluable asset in steel manufacturing and processing facilities.

Parameters:

Coil Weight: up to 6 000 kg

Throughput: 160–320 coils per 8-hour shift

Automation: semi-automatic or fully automatic modes

Materials: carbon steel, stainless steel, aluminum

Packaging: stretch film, VCI paper, steel straps

Safety: overload protection, emergency stops, advanced sensors

Slit Coil Handling and Packaging Line

Automated Solution for High-Speed and Safe Slit Coil Logistics

The Slit Coil Handling and Packaging Line automates the complete process of receiving, conveying, buffering, wrapping, weighing, labeling, and stacking slit coils.

It reduces labor, improves safety, and ensures consistent export-grade packaging.

Quick Overview

| Item | Specification |

|---|---|

| Coil ID | 400–600 mm |

| Coil OD | 800–1800 mm |

| Coil Width | 50–600 mm |

| Max Coil Weight | 2500–5000 kg |

| Line Speed | 12–24 coils/hour |

| Packaging Materials | Stretch film, HDPE, woven fabric, paper |

| Automation Level | Semi / Fully Automatic |

| Control System | PLC + HMI |

| Optional Modules | Labeling, weighing, stacking, strapping |

System Modules

1) Coil Receiving & Buffering

- Automatic centering

- Powered conveyor

- Continuous material feeding

2) Coil Turning & Orientation

- Stable coil positioning

- Protects edges from damage

3) Automatic Wrapping & HDPE Applying

- Stretch film + HDPE multi-layer protection

- Automatic cutting and sealing

4) Weighing & Labeling (Optional)

- Inline weighing

- Automatic barcode/QR labeling

5) Stacking & Palletizing

- Hydraulic or robotic stacking

- Safe coil pressing to prevent shifting

6) Conveyor System

- Smooth transfer

- Anti-vibration, low-noise

- Modular sections for flexible layout

Key Features & Benefits

- High-Level Automation reduces labor dependence by 80%+

- Fast Packaging Speed supports continuous slit coil production

- Damage-Free Handling through optimized coil support and alignment

- Consistent Export Packaging with stable tension and uniform finish

- Improved Workplace Safety by eliminating manual lifting

- Flexible Layout Options for various factory configurations

Why Choose Us?

- 15+ years in coil packaging automation

- Installations across Europe, Mexico, Russia, India, UAE

- Strong after-sales support with remote + onsite service

- Modular design that supports future expansion

Downloadable Documents

- Product Brochure (PDF)

- Layout Drawing (PDF / DWG)

- Electrical Diagram

- Installation Requirements

- Case Study Report

Application Industries

- Steel coil service centers

- Slitting line workshops

- Metal processing plants

- Rolling mills

- Wire & cable factories

- Stainless steel & aluminum coil producers

Video Demonstration

Recommended videos:

- Complete workflow: feeding → buffering → wrapping → stacking

- Before/after packaging comparison

Successful Case Studies

Case 1 — Mexico

- Output increased from 120 → 210 coils/day

- Labor reduced from 5 → 2 operators

Case 2 — Russia

- Inline weighing & ERP-connected label system

- 20 coils/hour stable throughput

Case 3 — India

- Production speed improved 3×

- 18% material saving via optimized wrapping logic

FAQ

Installation Time?

10–20 days depending on line configuration.

Layout Customization?

Yes, 2D/3D CAD layout provided.

Required Materials?

Stretch film, HDPE sheet, woven tape, paper belt.

Operators Needed?

1 operator for monitoring.

After-Sales Service?

Remote support, onsite installation, spare parts available.

Get a Free Quote

We provide:

- Technical consultation

- Layout design (PDF/CAD)

- Budgetary quotation

- Material consumption estimation

- Cycle time analysis

A stainless steel coil packing line streamlines the packaging process, providing consistent, high-quality protection for stainless steel coils. Featuring automated functions like wrapping, strapping, and stacking, it enhances productivity, reduces manual labor, and safeguards coils from damage during transit, making it ideal for industrial packaging needs.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

Automatic Steel Coil Strapping

The Automatic Steel Coil Strapping Line is a cutting-edge solution designed for efficient and secure steel coil packaging

View DetailsAutomatic Steel Coil Packing Sy

The automatic steel coil strapping package line provides a reliable solution for securing steel coils with precision and

View DetailsCold Roll Steel Coil Strapping

A Cold Roll Steel Coil Strapping & Packing Line Manufacturer specializes in efficient, durable strapping and packaging so

View DetailsAutomated Steel Coil Packaging

The Steel Coil Packaging Line is an industrial solution tailored to efficiently package steel coils with precision and sa

View DetailsStainless Steel Coil Packing Li

The stainless steel coil packing line is designed to efficiently secure and protect stainless steel coils during transpor

View Details