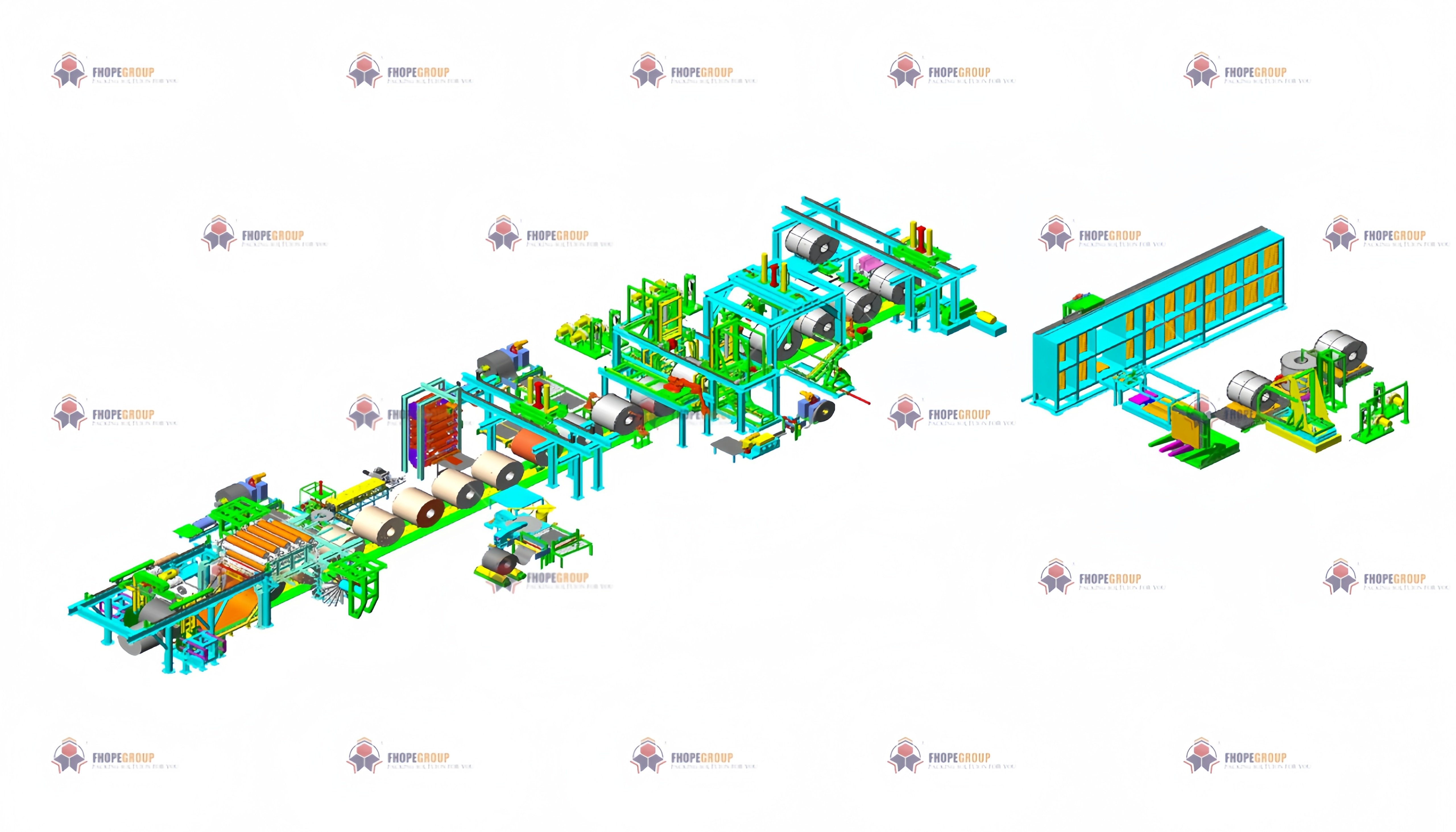

Stainless Steel Coil Packing Line

Project Information

The copper coil stacking machinery integrates multiple functions, including separating, strapping, stacking, and weighing copper coils (width: 10mm–300mm). It operates under a supervisory control system with manual operation options for individual components.

Key Features:

Composed of turnstile, coil separator, weighing device, strapping machine, stacking system, and conveyor line.

Equipped with a built-in hydraulic press station.

Requires user-provided power and air supply.

Wuxi BuHui’s Stainless Steel & Alloy Coil Packing Line automates separation, strapping, edge protection, wrapping, and stacking—delivering consistent, damage-free coils with minimal labor and seamless integration.

The Challenge: Manual, Fragmented Coil Packaging

- Labor-intense handling: Manual separation, strapping, and stacking drive up costs and safety risks.

- Inconsistent quality: Variable tension and positioning cause edge damage and rework.

- Multi-material demands: Frequent adjustments needed for steel, copper, aluminum, and alloy coils.

- Layout constraints: Disconnected modules disrupt flow and complicate factory layouts.

- Safety & downtime: Lack of real-time monitoring increases accident potential and stoppages.

- Poor visibility: No centralized control slows troubleshooting and maintenance planning.

Solution: Key Features & Benefits

| Feature / Component | Benefit / ROI |

|---|---|

| Turnstile & Coil Separator | Automates orientation & separation—cuts manual handling and ergonomic risk. |

| Weighing Device | Inline coil weighing feeds accurate data for ERP/MES traceability. |

| Supervisory PLC/HMI | Unified interface for recipes, real-time monitoring, alarms, and manual override. |

| Hydraulic Press Station | Stabilizes edges pre-strapping for uniform tension and slip-free straps. |

| Automatic PP Strapping | Precision-tensioned straps secure coils uniformly for transport. |

| Downender & Conveyor Integration | Safe lowering and transfer streamline flow to wrapping or stacking. |

| Stacking System | Orders wrapped coils onto pallets—reduces labor and speeds dispatch. |

| Modular Layout | Custom station placement adapts to footprint and future growth. |

| Real-Time Alarms | Instant fault detection minimizes downtime. |

| Manual Override | Each module can operate independently for setup or emergencies. |

Technical Specifications

| Parameter | Specification |

|---|---|

| Coil Weight Capacity | 100–3,000 kg |

| Coil Width Range | 10–300 mm |

| Package OD | 600–1,500 mm |

| Roller Speed | 2–4 m/min |

| Wrapping Time | 20–60 s per coil |

| Strapping Material | PP belt, ID 50 mm, width 100 mm |

| Power | 380 V/60 Hz, ~3.6 kW |

| Air Supply | 4–6 kgf/cm² |

| Control | PLC/HMI with data logging & recipe library |

| Safety | Guarding, interlocks, light curtains, E-stops |

Why Wuxi BuHui?

- Fully integrated: One line handles separation, strapping, press, wrapping, and stacking.

- Multi-material ready: Configurable for stainless steel, copper, aluminum, and alloy coils.

- Central control: Real-time monitoring and manual override boost uptime.

- Modular & scalable: Station placement adapts to layout and future needs.

- Safety-first: Automated handling with alarms protects operators.

Request a Quote

Ready to upgrade your coil packing line? Contact Wuxi BuHui with your specs for a tailored solution and competitive quote.

The stainless steel coil packing line is designed to efficiently secure and protect stainless steel coils during transportation and storage. With automated wrapping, strapping, and palletizing features, it minimizes handling time while ensuring coils remain in pristine condition, reducing damage risk and optimizing overall packaging operations for industrial use.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

Automatic Steel Coil Strapping

The Automatic Steel Coil Strapping Line is a cutting-edge solution designed for efficient and secure steel coil packaging

View DetailsAutomatic Steel Coil Packing Sy

The automatic steel coil strapping package line provides a reliable solution for securing steel coils with precision and

View DetailsCold Roll Steel Coil Strapping

A Cold Roll Steel Coil Strapping & Packing Line Manufacturer specializes in efficient, durable strapping and packaging so

View DetailsAutomated Steel Coil Packaging

The Steel Coil Packaging Line is an industrial solution tailored to efficiently package steel coils with precision and sa

View DetailsSlit Coil Handling and Packagin

A stainless steel coil packing line streamlines the packaging process, providing consistent, high-quality protection for

View Details