Revolutionize Your Mold Handling Operations Safely

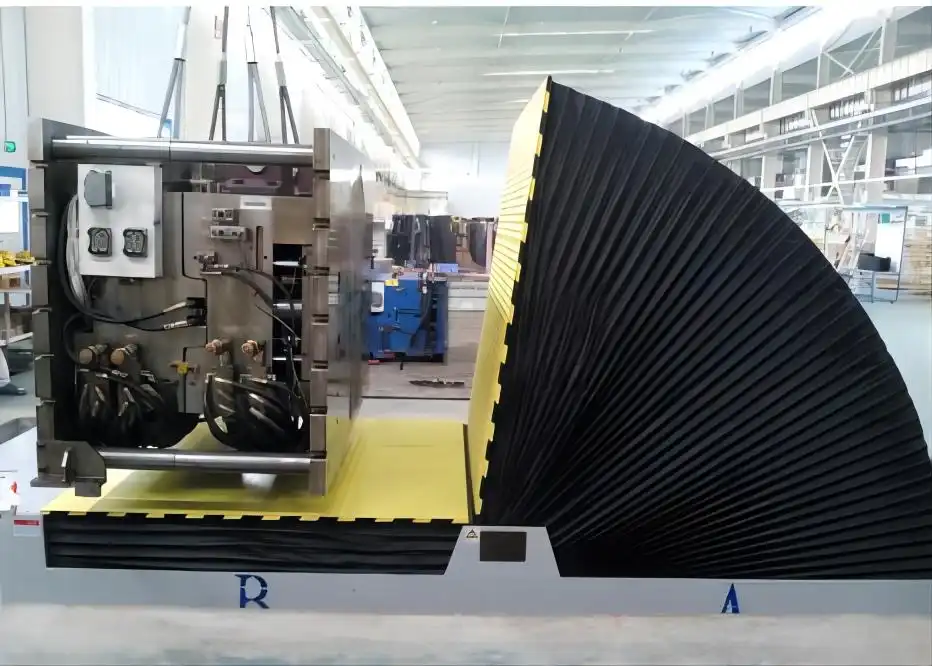

Our industrial mold upender systems eliminate manual handling risks while providing precise rotation control for heavy molds and industrial components.

Precision Rotation Control

Achieve exact angular positioning from 0-180 degrees with our hydraulic or motor-driven rotation systems for optimal mold access.

Heavy Load Capacity

Handle industrial molds weighing up to 20 tons with our reinforced steel construction and balanced weight distribution technology.

Flexible Power Options

Choose between hydraulic systems for maximum power or electric motors for clean operation in sensitive manufacturing environments.

Enhanced Worker Safety

Automated mold positioning eliminates manual handling risks, reducing workplace injuries and improving operational efficiency by 65%.

Project Overview & Advantages

Explore our specialized capabilities and successful case studies across various manufacturing sectors

Mold Upender Manufacturing Excellence

Enhance your mold handling operations with our mold upender, mold tilter, and mold turning machine. Designed for precision and safety, these machines simplify the process of tilting and rotating heavy molds. Ideal for various industries, they improve efficiency, reduce labor effort, and ensure smooth operations. Invest in reliable, high-performance equipment tailored to your production needs.

Mechanical upender

Discover affordable solutions for handling heavy materials with our mechanical coil upender, coil tilter, and mold upending machine. Designed for efficiency and safety, these machines simplify operations while reducing costs. Perfect for industries needing reliable equipment without breaking the budget. Upgrade your workflow today with our competitively priced, high-performance machinery tailored

Hydraulic upender

A hydraulic upender is an industrial machine designed to safely and efficiently tilt or rotate heavy loads, such as steel coils, molds, or other bulky items. Using hydraulic power, it ensures precise handling, reduces labor strain, and enhances workplace safety. Its robust construction and customizable features make it ideal for manufacturing, warehousing, and heavy-duty operations.

Coil Upender

Find reliable solutions for heavy material handling with our coil upender, designed to improve efficiency and safety in industrial operations. Partner with a trusted coil upender manufacturer to ensure high-quality, durable equipment tailored to your specific needs. Enhance your workflow today with innovative and cost-effective solutions for your business.

Mold Upender

Enhance your mold handling operations with our mold upender, mold tilter, and mold turning machine. Designed for precision and safety, these machines simplify the process of tilting and rotating heavy molds. Ideal for various industries, they improve efficiency, reduce labor effort, and ensure smooth operations. Invest in reliable, high-performance equipment tailored to your production needs.

Mold Flipper

A mold flipper is a specialized machine designed to rotate or flip molds safely and efficiently during manufacturing processes. It reduces manual handling, minimizes the risk of damage to molds, and improves workplace safety. With its precise and reliable operation, a mold flipper is essential for industries working with heavy or complex molds.

Hydraulic Dumper

Wuxi BuHui’s Hydraulic Dumper delivers effortless elevation and tipping of heavy boxes and containers—streamlining your workflow, boosting throughput, and enhancing operator safety with smooth, reliable performance.

Precision Mold Upender Systems

Our heavy-duty mold upender equipment revolutionizes industrial mold handling with robust engineering and intelligent control systems, delivering seamless rotation and positioning for molds weighing up to 20 tons across various manufacturing environments.

Dual-Power Operation: Flexible hydraulic and electric drive systems adaptable to different factory power configurations and operational requirements.

Precision Angle Control: Advanced positioning technology enables exact mold rotation from 0-180 degrees with ±1° accuracy for perfect alignment.

Universal Compatibility: Engineered to handle diverse mold types including injection, compression, and blow molds with custom clamping options.

Operation Time Reduction

Manual Labor Decrease

Safety Incident Prevention

Years Operational Lifespan

Automotive Mold Facility Productivity Enhancement

Operational Challenge

A prominent automotive components manufacturer struggled with manual mold handling processes, experiencing frequent production bottlenecks, worker safety concerns, and substantial mold damage incidents affecting their bottom line.

Engineering Implementation

We installed three heavy-duty mold upender systems with customized rotating platforms and intelligent control interfaces. The implementation resulted in 65% faster mold changeover, eliminated product damage, and reduced required operators from four to one per shift.

Request Your Custom Solution

SHOWCASE & NEWS

Industrial Mold Upender Solutions FAQ

Expert Answers to Your Mold Handling Equipment Questions

A mold upender is specialized industrial equipment designed to safely rotate and position heavy molds in manufacturing facilities. Utilizing either electric motor or hydraulic power systems, it precisely lifts and turns molds up to 90 degrees or more, enabling optimal access for maintenance, cleaning, and production processes. This industrial rotation equipment eliminates the need for risky manual handling while significantly reducing mold changeover time by up to 70%. The machinery ensures perfect positioning accuracy, protecting valuable molds from damage during orientation changes.

Our mold upenders integrate multiple safety systems including emergency stop buttons, overload protection sensors, anti-slip platforms, and dual-hand operation requirements. All electrical components comply with UL standards, while mechanical systems meet CE certification requirements. Additional safety features include automatic locking mechanisms at various rotation angles, warning lights and alarms, and protective guarding around moving parts. These industrial safety measures reduce workplace accidents by over 85% compared to manual mold handling methods, ensuring complete operator protection during heavy mold rotation operations.

Our mold turning equipment accommodates an extensive range of specifications, with standard models handling weights from 1 to 30 tons. Custom solutions are available for ultra-heavy molds up to 50 tons. The machines support mold dimensions ranging from compact 500mm x 500mm units to large-scale 2500mm x 2500mm configurations. Specialized adaptations include adjustable clamping systems for irregular mold shapes, extended arms for oversized components, and precision rotation controls for delicate mold surfaces. This flexibility ensures compatibility with injection molds, compression molds, and various industrial tooling across multiple sectors.

Standard installation timelines range from 3-6 weeks depending on equipment complexity and site preparation requirements. The process includes: 1 week for foundation preparation and power connection, 1-2 weeks for mechanical assembly and positioning, 1 week for electrical integration and safety system verification, and 3-5 days for comprehensive testing and staff training. Our installation teams work around your production schedule to minimize disruption, with many clients achieving full operational status within one month of equipment delivery. We provide detailed installation checklists and progress updates throughout the implementation phase.

Our mold upenders are engineered for minimal maintenance with straightforward service requirements. Daily operations require only visual inspections (5-10 minutes). Weekly maintenance involves lubrication point checks and bolt tightness verification (30-45 minutes). Monthly servicing includes hydraulic system checks, electrical connection inspections, and safety system testing (2-3 hours). We provide comprehensive maintenance manuals, video tutorials, and optional remote diagnostic support. With proper care, our mold rotation equipment delivers reliable performance for 15+ years, maintaining 98% operational availability in continuous manufacturing environments.

Absolutely. Our mold upending systems feature flexible integration capabilities with existing production lines and manufacturing workflows. Standard models include programmable logic controllers with communication protocols compatible with most industrial automation systems. Customizable interfaces allow synchronization with overhead cranes, conveyor systems, and factory management software. Integration options include barcode scanning for mold identification, automated height adjustment for different mold sizes, and data logging for maintenance scheduling. Our engineering team works directly with your technical staff to ensure seamless implementation within your specific manufacturing environment.

Our Clients Around The World

We are honored to serve outstanding enterprises worldwide, establishing long-term stable partnerships. Below are some of our trusted partners who have chosen our manufacturing solutions.

Ready to Start Your Next Manufacturing Project?

Impressed by our projects? If you have similar requirements or want to discuss your project ideas, contact our expert team immediately for a free initial consultation.

Contact Our Experts