Eliminate Steel Coil Handling Inefficiencies

Discover how our automated coil packing systems transform your production workflow, delivering unmatched precision and reliability for demanding industrial environments.

Throughput Limitations

Outdated equipment creates production bottlenecks that delay shipments and affect your supply chain reliability.

Material Waste Issues

Inefficient packing processes consume excessive materials, directly impacting your operational budget and sustainability goals.

Protection Deficiencies

Inadequate coil wrapping results in surface damage and corrosion during transit, leading to customer complaints and financial losses.

Equipment Reliability

Frequent machine breakdowns cause unexpected downtime, disrupting your production schedule and maintenance planning.

Project Overview & Advantages

Explore our specialized capabilities and successful case studies across various manufacturing sectors

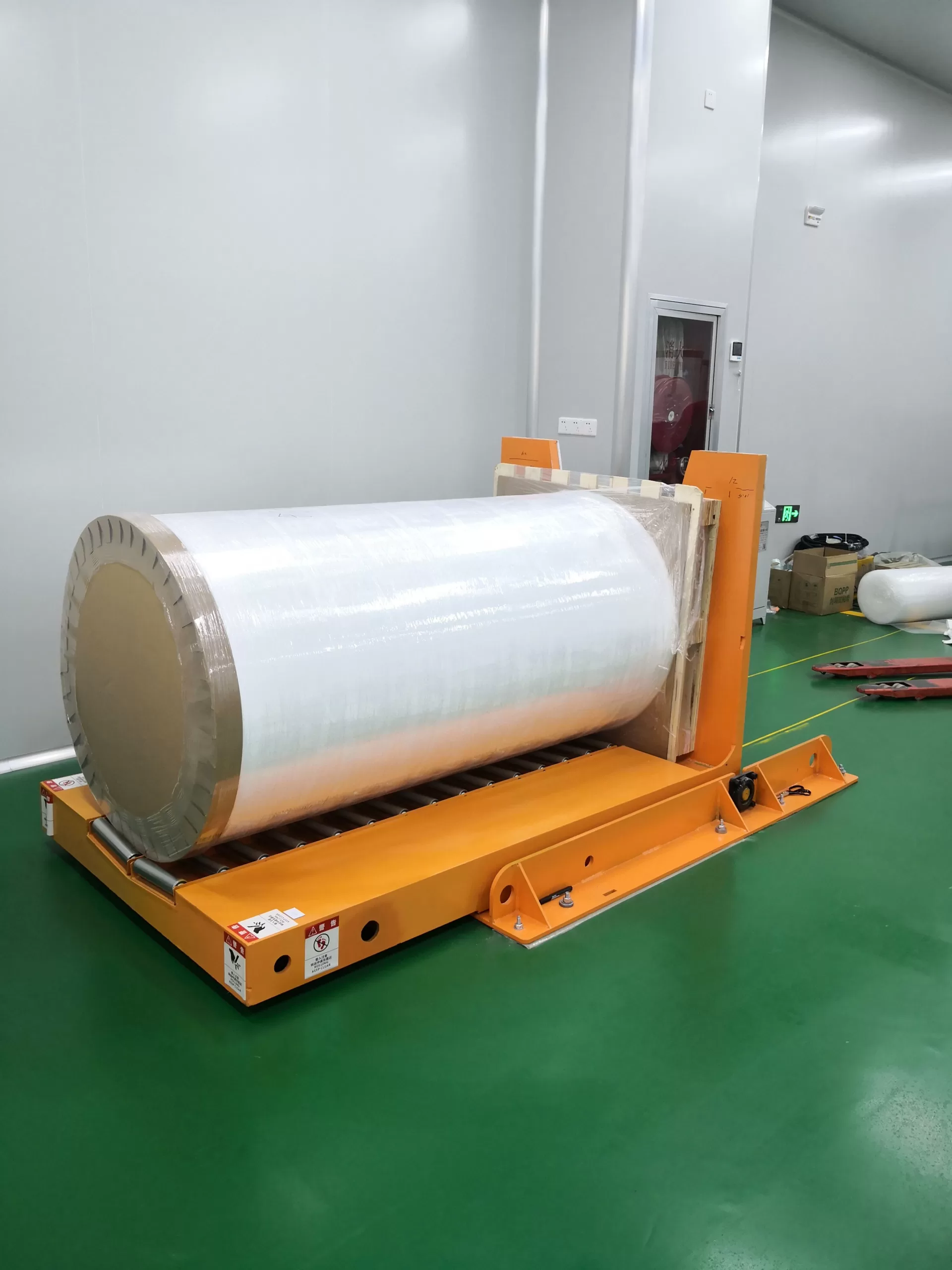

Hydraulic upender Manufacturing Excellence

A hydraulic upender is an industrial machine designed to safely and efficiently tilt or rotate heavy loads, such as steel coils, molds, or other bulky items. Using hydraulic power, it ensures precise handling, reduces labor strain, and enhances workplace safety. Its robust construction and customizable features make it ideal for manufacturing, warehousing, and heavy-duty operations.

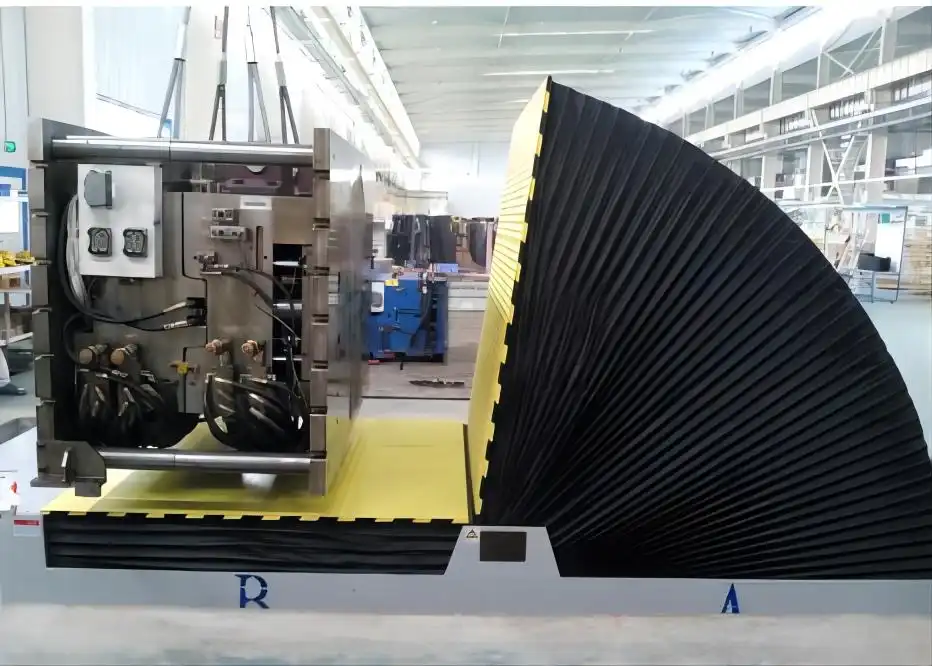

Mechanical upender

Discover affordable solutions for handling heavy materials with our mechanical coil upender, coil tilter, and mold upending machine. Designed for efficiency and safety, these machines simplify operations while reducing costs. Perfect for industries needing reliable equipment without breaking the budget. Upgrade your workflow today with our competitively priced, high-performance machinery tailored

Hydraulic upender

A hydraulic upender is an industrial machine designed to safely and efficiently tilt or rotate heavy loads, such as steel coils, molds, or other bulky items. Using hydraulic power, it ensures precise handling, reduces labor strain, and enhances workplace safety. Its robust construction and customizable features make it ideal for manufacturing, warehousing, and heavy-duty operations.

Coil Upender

Find reliable solutions for heavy material handling with our coil upender, designed to improve efficiency and safety in industrial operations. Partner with a trusted coil upender manufacturer to ensure high-quality, durable equipment tailored to your specific needs. Enhance your workflow today with innovative and cost-effective solutions for your business.

Mold Upender

Enhance your mold handling operations with our mold upender, mold tilter, and mold turning machine. Designed for precision and safety, these machines simplify the process of tilting and rotating heavy molds. Ideal for various industries, they improve efficiency, reduce labor effort, and ensure smooth operations. Invest in reliable, high-performance equipment tailored to your production needs.

Mold Flipper

A mold flipper is a specialized machine designed to rotate or flip molds safely and efficiently during manufacturing processes. It reduces manual handling, minimizes the risk of damage to molds, and improves workplace safety. With its precise and reliable operation, a mold flipper is essential for industries working with heavy or complex molds.

Hydraulic Dumper

Wuxi BuHui’s Hydraulic Dumper delivers effortless elevation and tipping of heavy boxes and containers—streamlining your workflow, boosting throughput, and enhancing operator safety with smooth, reliable performance.

Industrial Hydraulic Upender Systems

Fhope's hydraulic upending machines provide stable, controlled rotation for heavy industrial materials, delivering superior performance in steel plants, manufacturing facilities, and logistics centers worldwide.

Advanced Hydraulic Control: Precision double-acting cylinders ensure smooth 90-degree rotation with minimal energy consumption.

Compact Platform Design: Space-efficient construction handles asymmetrical loads including long cylindrical materials.

Robust Safety Features: Integrated overload protection and emergency stop systems guarantee operational security.

Work Efficiency Improvement

Manual Labor Reduction

Operational Safety Rate

Space Utilization Optimization

Steel Processing Plant Implements Hydraulic Upending Solution

Operational Challenge

A major steel processing facility struggled with manual coil positioning, experiencing slow throughput and workplace safety concerns. Their existing methods couldn't handle varying coil sizes efficiently.

Fhope Engineering Solution

We installed a custom hydraulic upender system capable of handling coils from 5-25 tons. The implementation resulted in 300% faster material positioning, eliminated manual handling risks, and increased overall production line efficiency by 40%.

Request Custom Solution Quote

SHOWCASE & NEWS

Hydraulic Upender Solutions FAQ

Expert Answers to Your Hydraulic Upending Machine Questions

A hydraulic upender is an industrial machine designed to safely tilt and rotate heavy loads, particularly non-symmetrical items like long cylindrical objects. Utilizing double-acting hydraulic cylinders, these systems provide controlled rotation with exceptional stability. The compact platform design maximizes workspace efficiency while handling substantial weights. By automating the tilting process, hydraulic upending machines reduce manual labor requirements, minimize product damage risks, and can increase operational efficiency by up to 70% compared to manual handling methods.

Hydraulic upenders excel with non-symmetrical loads that require precise positioning. Ideal applications include long cylindrical objects, steel coils, industrial rolls, pipe sections, and elongated manufacturing components. The systems are particularly valuable for loads that are difficult to handle manually due to weight distribution challenges. With capacity ranges from 1 to 50 tons, these machines maintain stability while rotating awkwardly shaped items. The optimized platform design ensures secure positioning throughout the tilting cycle, making them perfect for manufacturing plants, steel service centers, and heavy equipment facilities.

Double-acting hydraulic cylinders provide superior control in both extension and retraction movements, ensuring smooth, precise load rotation. This dual-direction operation allows for exact positioning at any angle throughout the 90-degree tilting range. The hydraulic system delivers consistent power transmission, eliminating jerky movements that could compromise load stability. With precision flow control valves, operators can adjust rotation speed according to load characteristics. This technology enables handling of delicate or easily damaged materials with confidence, reducing product loss and improving workplace safety metrics significantly.

Modern hydraulic upenders incorporate multiple safety systems including emergency stop buttons, hydraulic safety valves, mechanical locking devices, and overload protection. The systems feature anti-slip platform surfaces, safety guards, and two-hand operation controls to prevent accidental activation. Advanced models include position sensors that automatically halt operation if irregular movement is detected. These comprehensive safety measures reduce workplace accidents by up to 85% compared to manual tilting operations. Regular safety audits and compliance with international standards ensure ongoing protection for both operators and equipment.

Yes, hydraulic upenders offer extensive customization options to match specific operational requirements. Modifications can include platform size adjustments from compact to extra-large dimensions, capacity enhancements from 1 to 50+ tons, and specialized surface treatments for unique load types. Control system integration allows compatibility with existing production lines, while various power options accommodate different facility capabilities. Special applications might include climate-resistant components for harsh environments or automated loading systems for high-volume operations. Our engineering team works directly with clients to develop tailored solutions that optimize workflow efficiency.

Proper maintenance involves daily visual inspections, weekly hydraulic system checks, and monthly comprehensive evaluations. Key maintenance tasks include monitoring hydraulic fluid quality, checking cylinder seals for wear, verifying structural integrity, and ensuring control system functionality. We recommend professional servicing every 1,000 operating hours or annually, whichever comes first. Our maintenance programs include remote monitoring capabilities that predict potential issues before they cause downtime. With proper care, hydraulic upenders typically deliver 15-20 years of reliable service, with many units remaining operational well beyond this timeframe in various industrial settings.

Our Clients Around The World

We are honored to serve outstanding enterprises worldwide, establishing long-term stable partnerships. Below are some of our trusted partners who have chosen our manufacturing solutions.

Ready to Start Your Next Manufacturing Project?

Impressed by our projects? If you have similar requirements or want to discuss your project ideas, contact our expert team immediately for a free initial consultation.

Contact Our Experts