Revolutionize Your Steel Coil Protection with Intelligent Packaging

Discover how our automated steel coil packing systems eliminate production bottlenecks while ensuring superior corrosion protection and handling safety for your valuable coils.

Throughput Optimization

Our automated steel coil packing line processes up to 15 coils per hour, eliminating manual handling constraints and production delays.

Cost Reduction

Reduce packaging labor costs by 60% and minimize material waste with precision-controlled wrapping systems.

Consistent Quality

Achieve uniform wrapping tension and complete surface coverage for optimal corrosion prevention during transit and storage.

Enhanced Safety

Automated handling systems eliminate direct worker exposure to heavy coils, reducing workplace accidents by over 85%.

Join 200+ global steel manufacturers who trust our automated coil packaging systems for reliable performance and ROI.

Request Your Custom Solution

Project Overview & Advantages

Explore our specialized capabilities and successful case studies across various manufacturing sectors

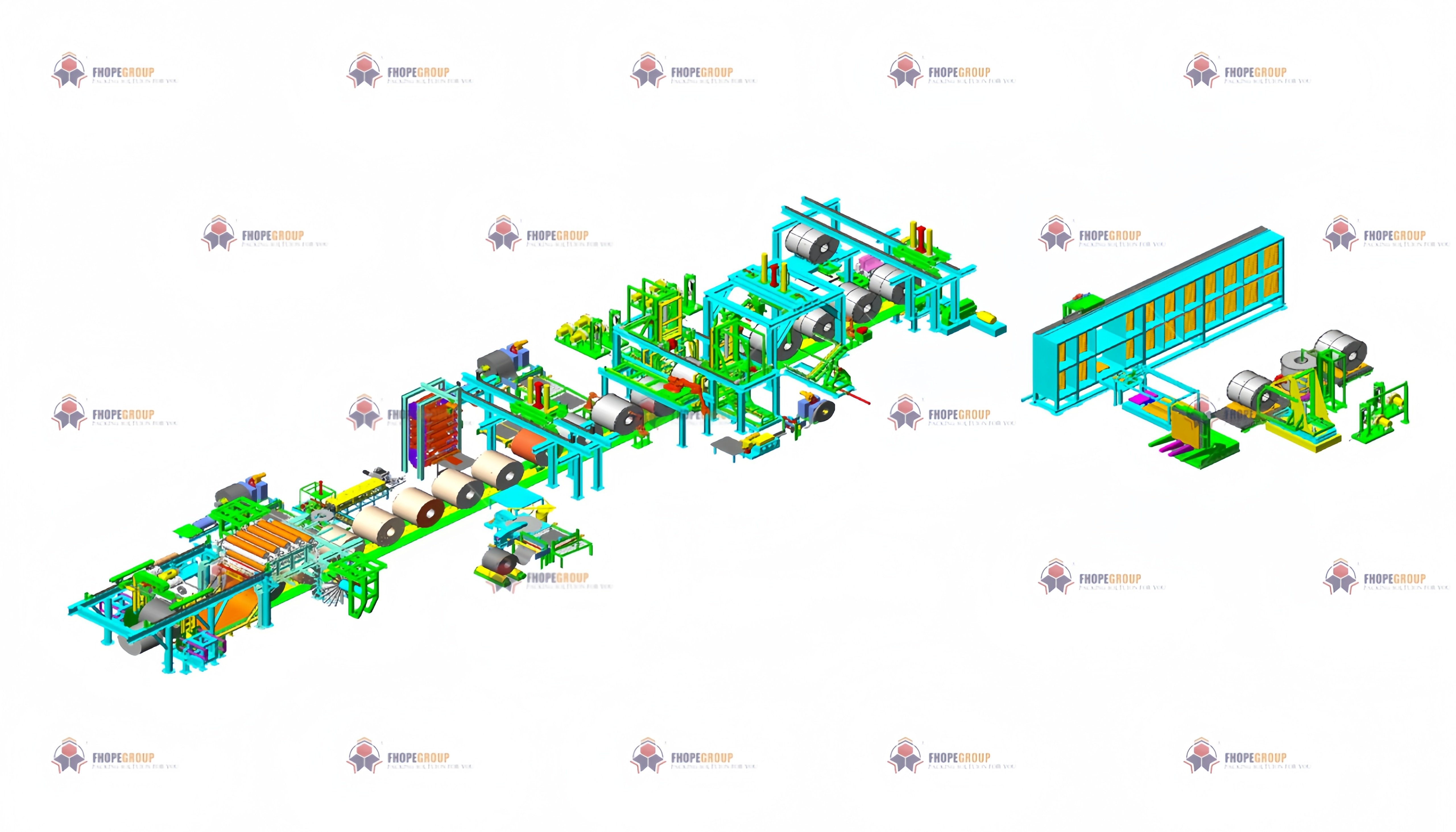

Steel coil packing line Manufacturing Excellence

Revolutionize your operations with an automated steel coil packing solution designed for efficiency and precision. Discover how our advanced steel coil packing line enhances productivity, ensures safe handling, and reduces operational costs – your key to streamlined manufacturing success.

Steel coil packing line

Revolutionize your operations with an automated steel coil packing solution designed for efficiency and precision. Discover how our advanced steel coil packing line enhances productivity, ensures safe handling, and reduces operational costs – your key to streamlined manufacturing success.

Copper coil packing line

Streamline your operations with a cutting-edge Copper Coil Packing Line. Discover how an Automated Copper Coil Packaging System enhances efficiency, reduces labor costs, and ensures secure handling. Optimize your production today!

Aluminum coil packing line

An Aluminum Coil Packing Line is a fully automated system designed to streamline the packaging process for aluminum coils. It ensures secure wrapping, strapping, and labeling, protecting coils from damage during storage or transport. This efficient solution enhances productivity, reduces labor costs, and meets industry standards for safe and reliable packaging.

Advanced Steel Coil Packing Line Solutions

Our automated steel coil packing solution revolutionizes industrial packaging with smart technology integration, delivering unmatched precision and reliability for heavy-duty coil protection across global manufacturing facilities.

Smart Operation Control: AI-driven monitoring systems optimize packaging parameters in real-time, ensuring consistent output quality with minimal supervision.

Adaptive Material Handling: Advanced sensor technology automatically adjusts to varying coil dimensions and surface characteristics for perfect wrapping every time.

Robust Construction: Heavy-duty components and precision engineering ensure reliable performance even in the most demanding industrial environments and conditions.

Faster Operation Speed

Reduced Operational Costs

System Uptime Reliability

Global Installations

European Steel Mill Automation Upgrade Case Study

Operational Challenge

A prominent European steel manufacturer struggled with inconsistent packaging quality and high labor dependency, leading to increased product damage during transit and rising operational expenses affecting their competitive edge.

Automation Implementation

We deployed a customized automated steel coil packing system featuring intelligent wrapping technology and precision strapping mechanisms. The solution achieved 18 coils per hour throughput with 98% packaging consistency and reduced material waste by 22%, delivering complete ROI within 14 months of operation.

Request Your Custom Solution

SHOWCASE & NEWS

Steel Coil Packing Line FAQ

Expert Answers to Your Steel Coil Packaging Questions

Our automated steel coil packing systems are engineered to process diverse coil types including hot-rolled, cold-rolled, galvanized, and stainless steel. They accommodate coils weighing 3-45 tons with outer diameters ranging from 500mm to 2500mm. Specialized configurations are available for delicate finishes and custom dimensions, ensuring optimal protection for every coil specification in your inventory.

Automated steel coil packing lines dramatically enhance throughput, processing 8-15 coils per hour compared to 2-4 with manual methods. This efficiency gain reduces labor requirements by 60-70% while eliminating consistency issues. Precision material application cuts film consumption by 25%, and integrated tracking systems provide real-time production data for better decision-making across your facility.

We utilize multi-layer protection systems tailored to your specific environmental challenges. Options include weather-resistant stretch film, anti-corrosion VCI paper, waterproof laminated barriers, and edge protectors. For international shipping, we incorporate desiccant systems and humidity indicators. Each material combination is tested to ensure it meets industry standards for corrosion protection and physical durability.

Absolutely. Our engineering team conducts comprehensive site assessments to design steel coil packing solutions that integrate seamlessly with your current operation. We adapt to space constraints, existing material handling equipment, and workflow patterns. Modular components allow for flexible configurations, whether you require inline processing, side-loading systems, or multi-station layouts for high-volume facilities.

We offer comprehensive support packages including on-site installation supervision, operator certification programs, and maintenance team training. Our remote diagnostic system enables real-time troubleshooting, reducing resolution time by up to 80%. Clients receive detailed documentation, video tutorials, and 24/7 access to our technical portal with spare parts ordering and service request capabilities.

Most facilities achieve full ROI within 18-30 months through multiple savings streams. Labor costs typically decrease by 65%, material waste drops 20-30%, and damage claims during transit are reduced by up to 90%. Additional benefits include increased throughput capacity, improved inventory accuracy, and enhanced compliance with customer packaging specifications. We provide detailed ROI analysis during the consultation phase.

```

Our Clients Around The World

We are honored to serve outstanding enterprises worldwide, establishing long-term stable partnerships. Below are some of our trusted partners who have chosen our manufacturing solutions.

Ready to Start Your Next Manufacturing Project?

Impressed by our projects? If you have similar requirements or want to discuss your project ideas, contact our expert team immediately for a free initial consultation.

Contact Our Experts